Mike99

Active Member

Hey Guys!

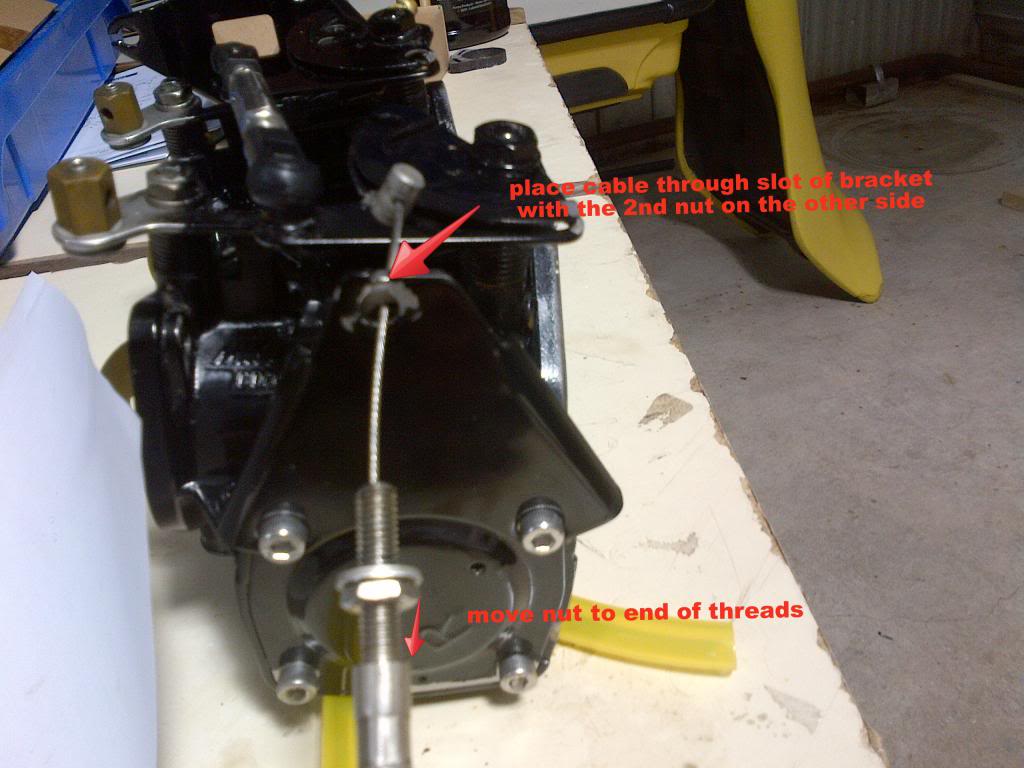

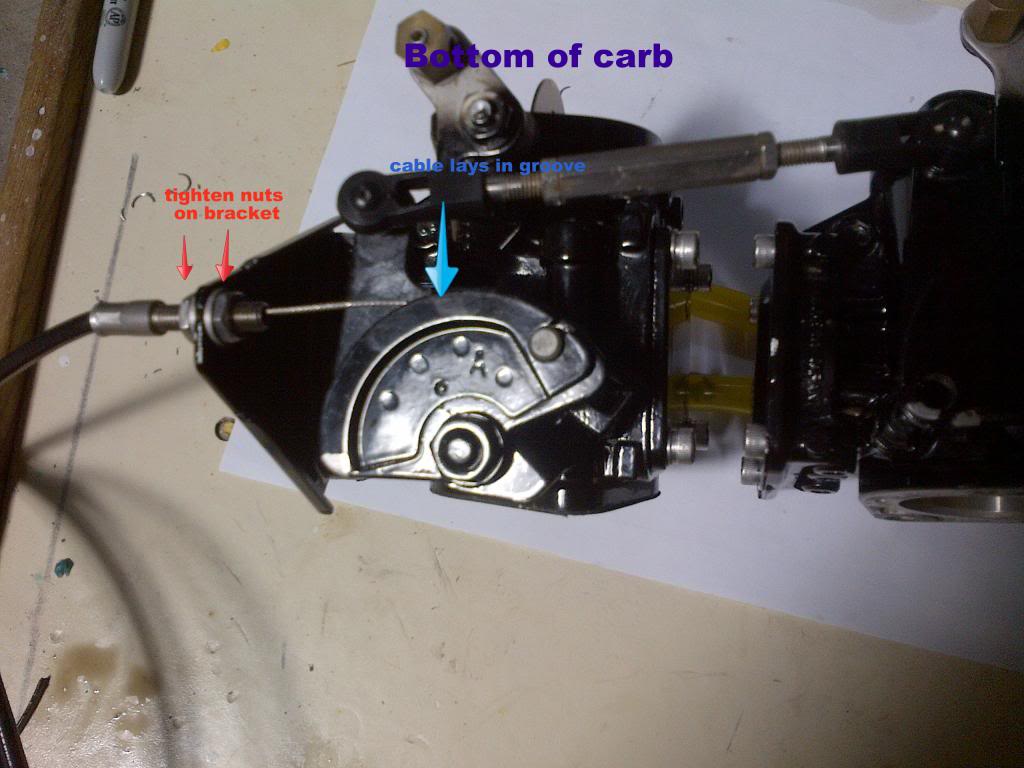

In prep for for changing out my oil and fuel lines this winter, I attempted to access the oil pump through the GTX glove box. My arms are not the longest, but I did manage to reach it. I was opening and closing the pump by hand, when the cable came loose off the pump. I managed to do my best imitation of Helen Keller, and was able to put the cable back on the pump. I noticed, though, that there seems to be some slack at both ends of the cable, and I can't see the alignment marks on the pump. The throttle is set up tight, with the slightest press of the throttle will move the butterflies. The oil pump does not kick in right away. I've included pictures of both ends of the cable for you guys to look at.

I'm not sure if it was tighter before I messed with it. I did notice that on one Helen Keller attempt, that the pump control wanted to turn farther than I should it have. It seems alright now, but does it have stops built into the pump? Maybe I was turning it the wrong way?? Could it be 360 degrees out, causing the slack?

Also, the oil pump adjustment mechanism on the carb seems impossible to adjust while the carbs are on the engine. How can you loosen the jam nut when you can't even feel it with your fingers??

Thanks!

Mike

In prep for for changing out my oil and fuel lines this winter, I attempted to access the oil pump through the GTX glove box. My arms are not the longest, but I did manage to reach it. I was opening and closing the pump by hand, when the cable came loose off the pump. I managed to do my best imitation of Helen Keller, and was able to put the cable back on the pump. I noticed, though, that there seems to be some slack at both ends of the cable, and I can't see the alignment marks on the pump. The throttle is set up tight, with the slightest press of the throttle will move the butterflies. The oil pump does not kick in right away. I've included pictures of both ends of the cable for you guys to look at.

I'm not sure if it was tighter before I messed with it. I did notice that on one Helen Keller attempt, that the pump control wanted to turn farther than I should it have. It seems alright now, but does it have stops built into the pump? Maybe I was turning it the wrong way?? Could it be 360 degrees out, causing the slack?

Also, the oil pump adjustment mechanism on the carb seems impossible to adjust while the carbs are on the engine. How can you loosen the jam nut when you can't even feel it with your fingers??

Thanks!

Mike