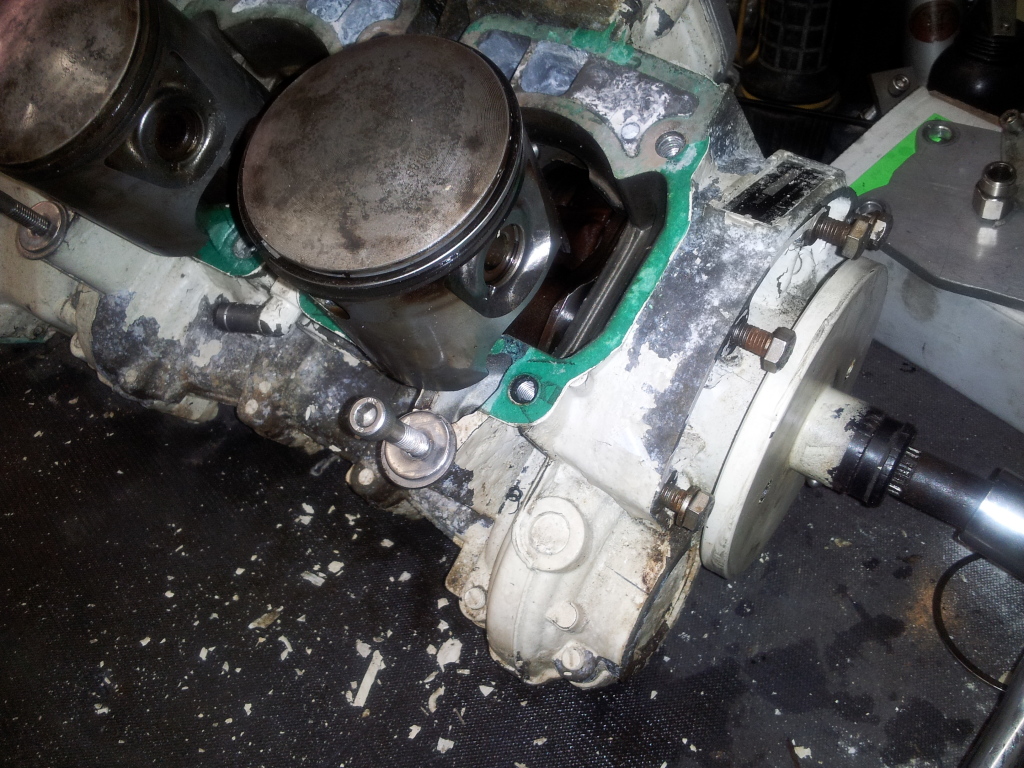

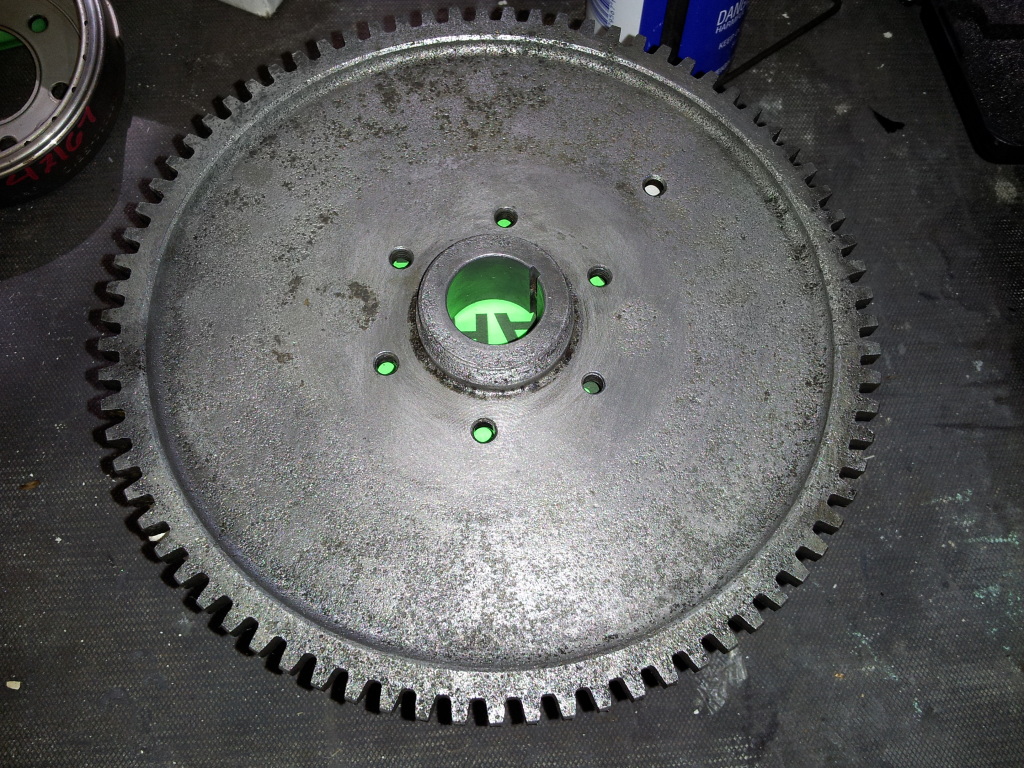

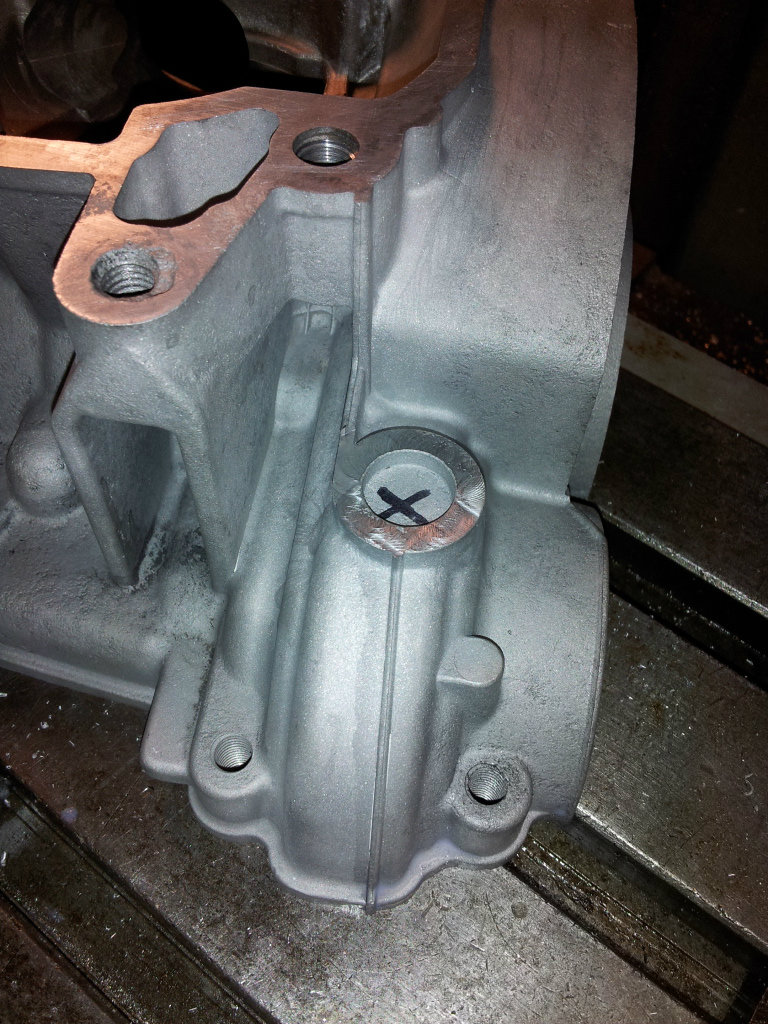

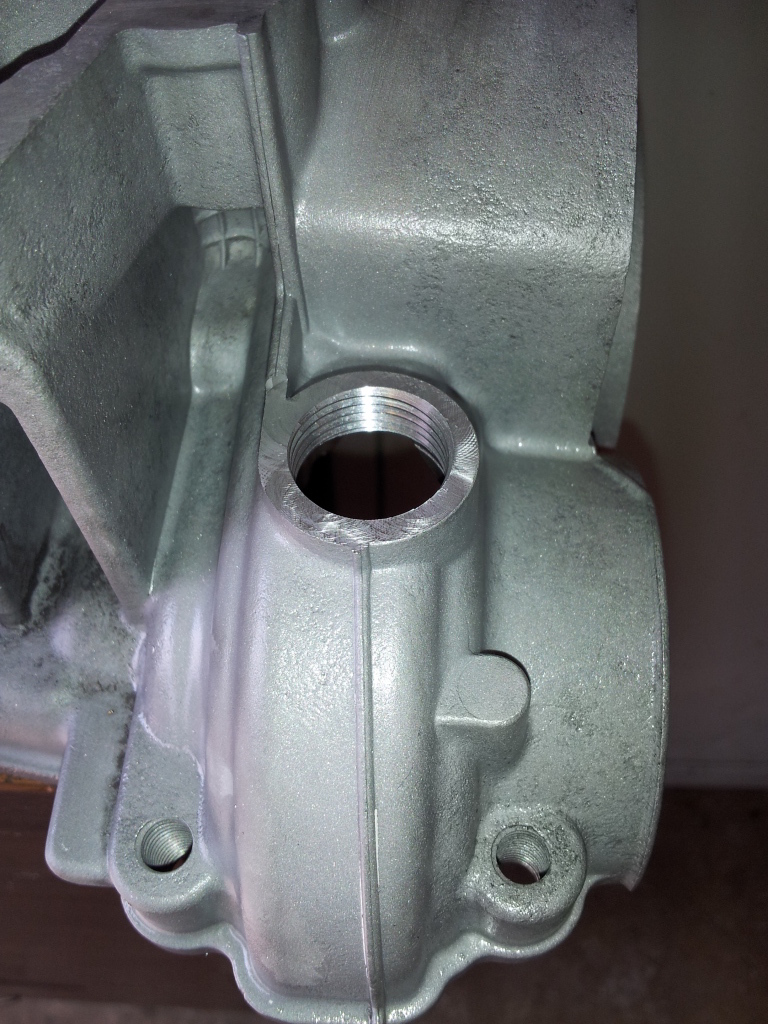

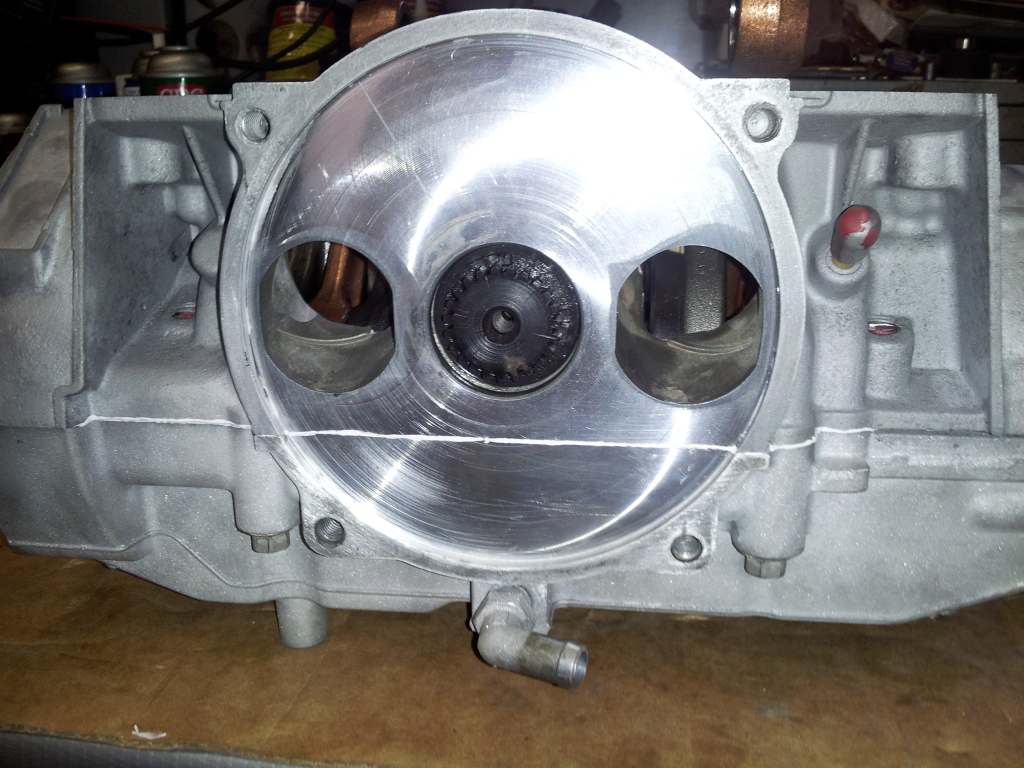

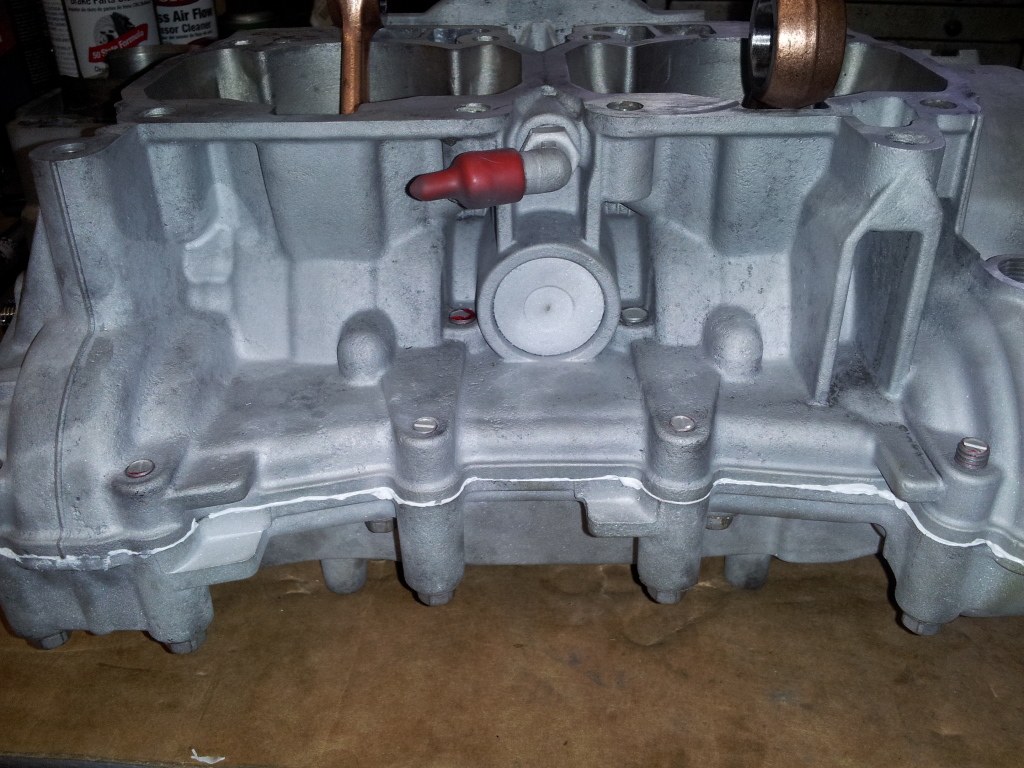

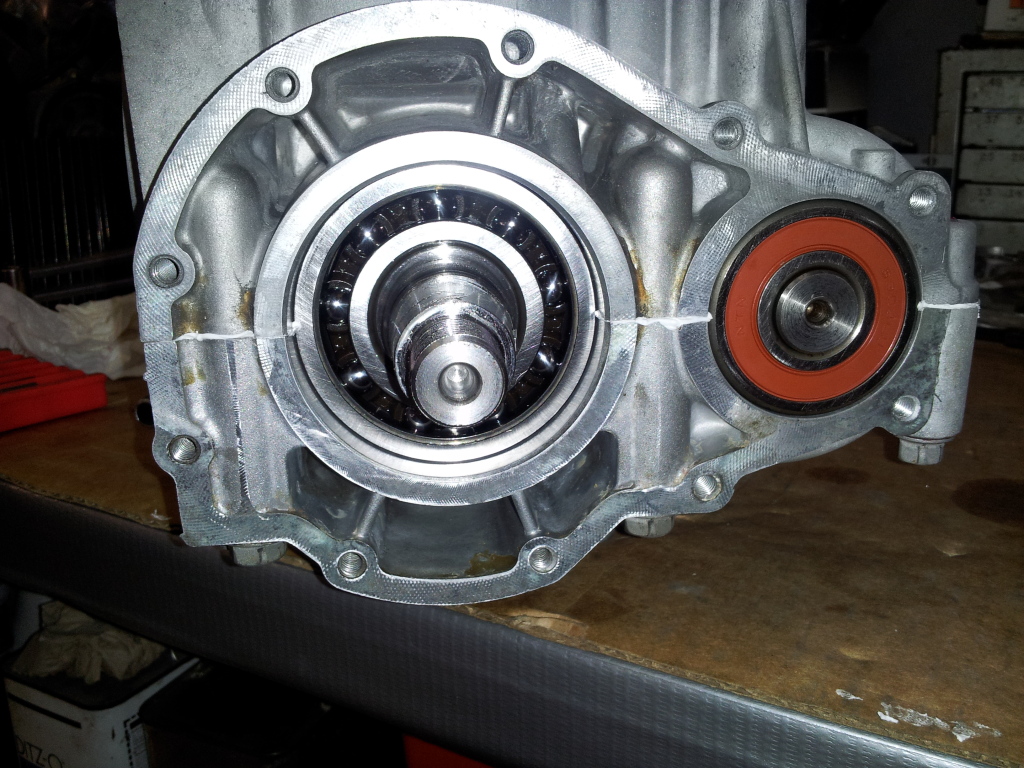

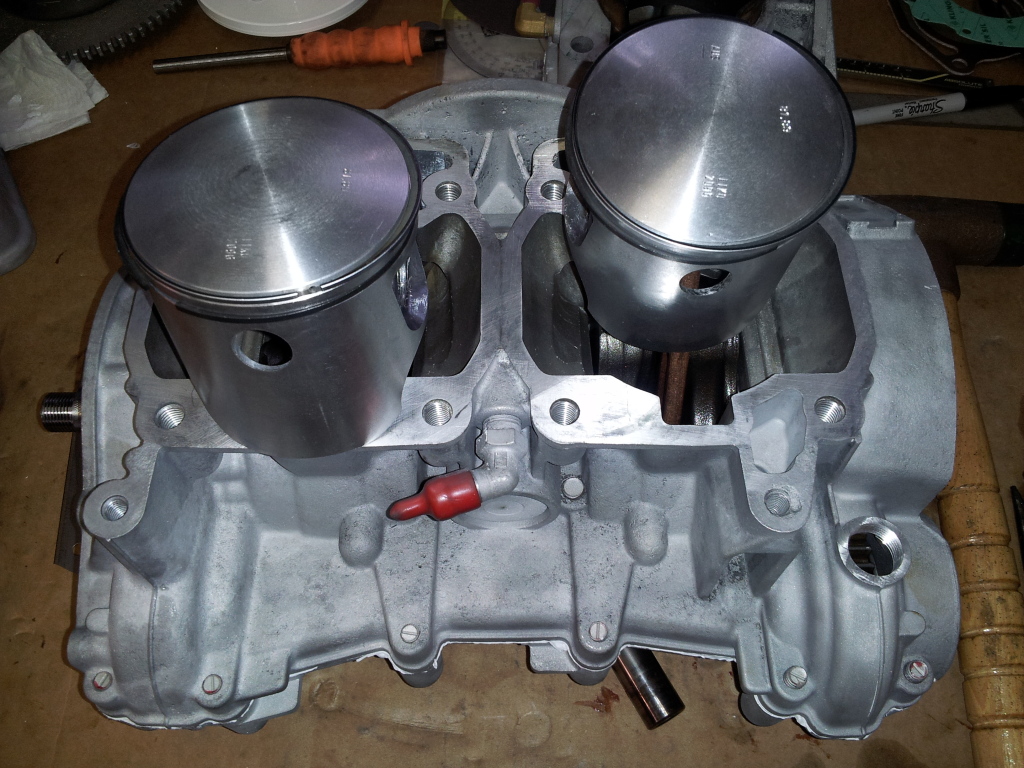

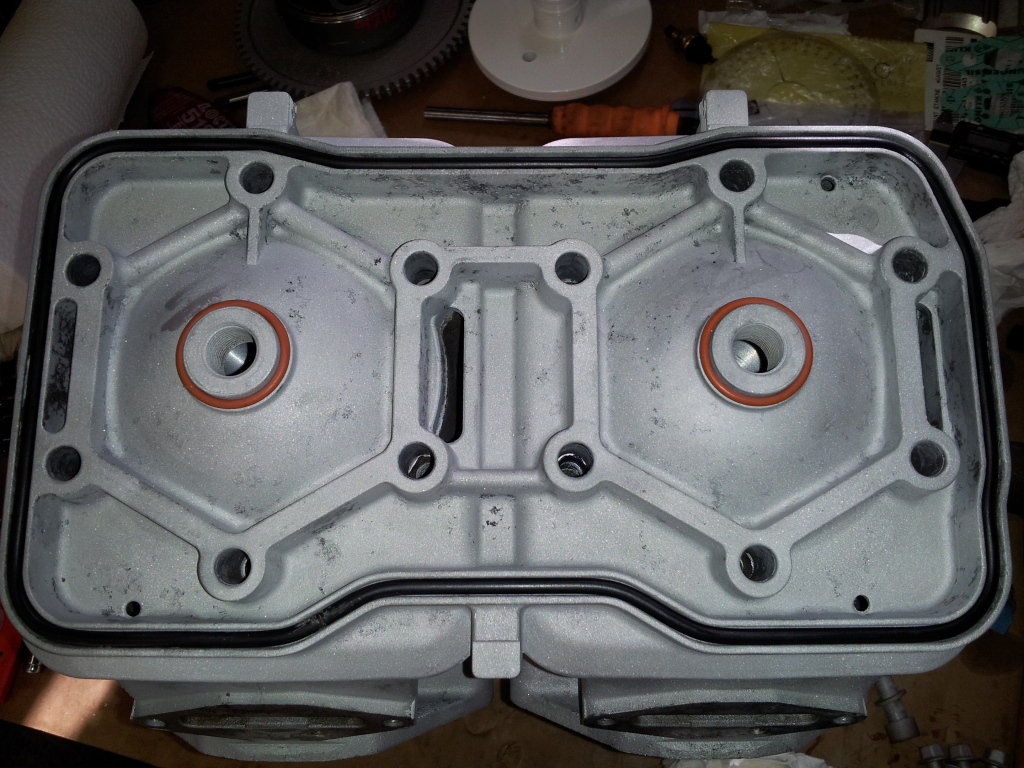

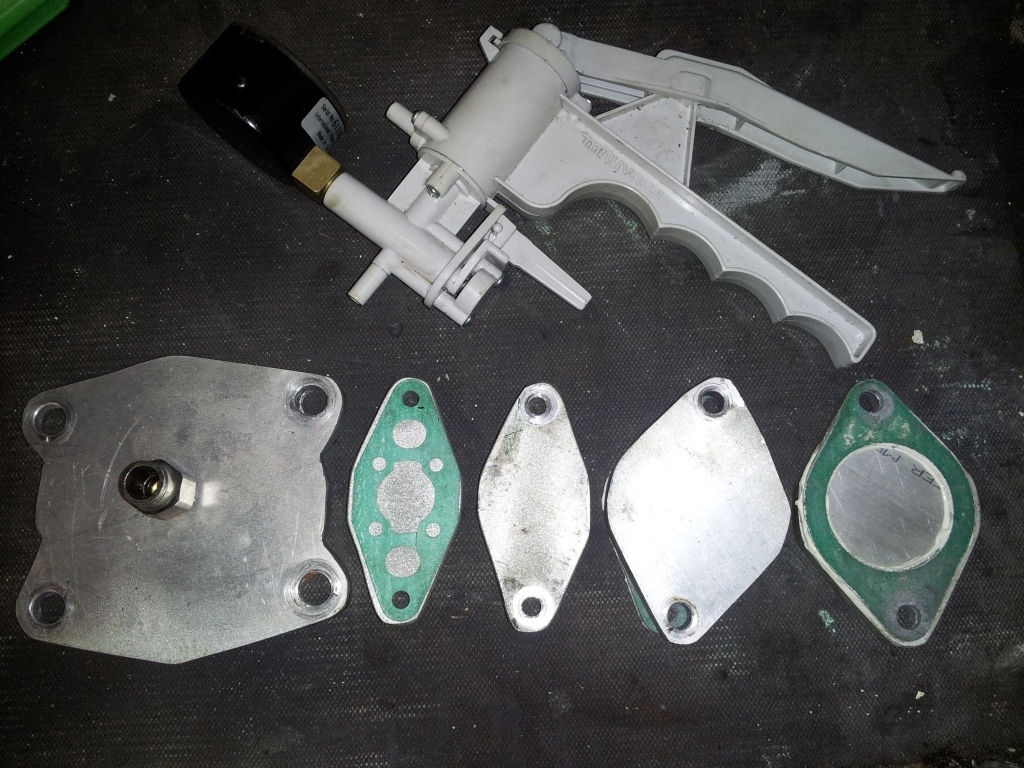

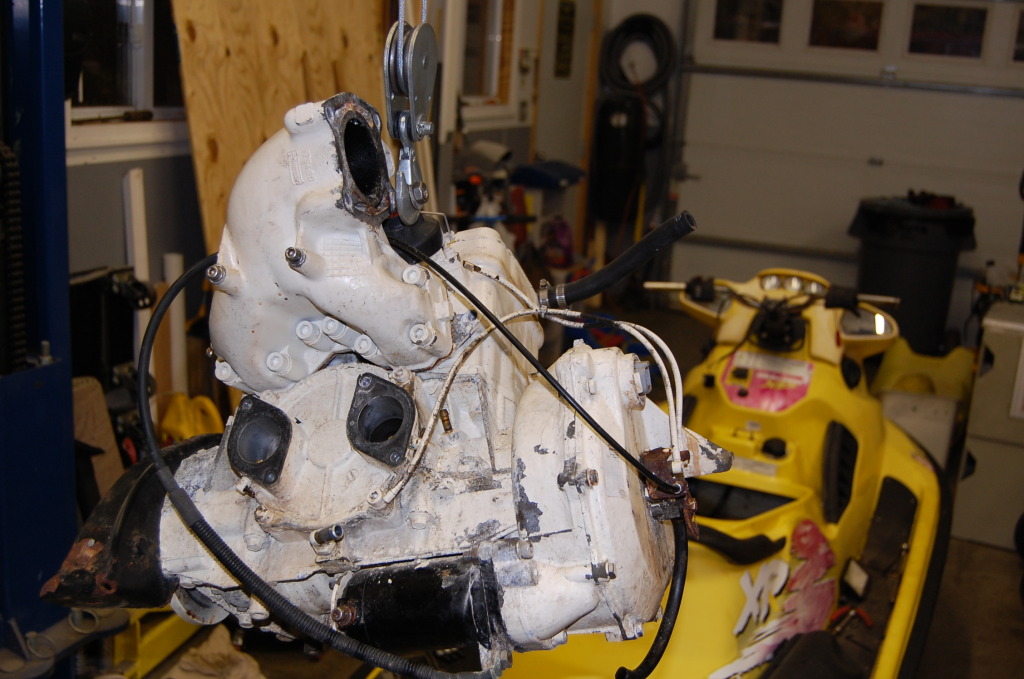

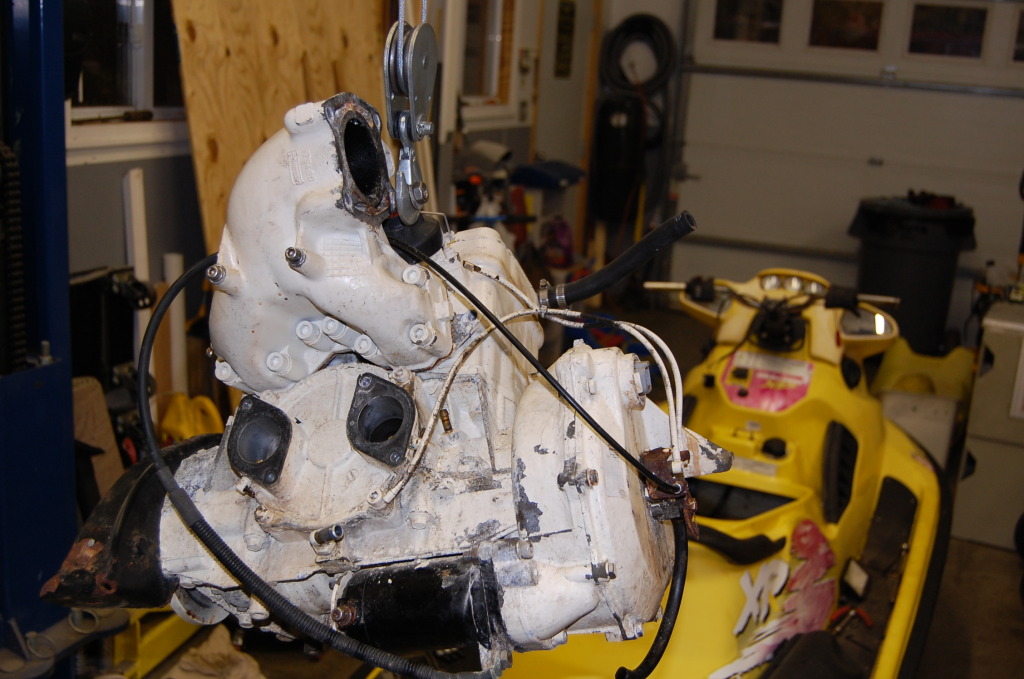

Alright, here it is, now that it is in my legal ownership(that was seedy at best) I can start the thread. I picked this XP up in the beginning of August, got nothing but a registration card, not in the sellers name, nor the seller to him, but the seller to him---did you get that one. But it all came back to me registered and titled in my name. It was tattered, well it was Clapped Out to say the least. It looks like it sat uncovered for who knows how long, engine looks like it spent time at the bottom of the ocean, it would barely turn over by hand. But hey, I was up for a project. So I got it home and tore into it to see just how bad it really is. Well, it's pretty sound just neglected. So, I yanked the engine, and stripped the hull internally. Then had at it with the Castrol Super Clean, the inside now looks like new. The project turned around at that point, next the outside of the hull. Stripped the graphics---that was tough for me to let go of. I think I may be the only one who actually likes them. I had new 96 XP's back in the day, they were the first NEW skis I bought. I'm also a bit of a purist when it comes to things original. So let the resto process begin. I'll post up as things progress.

Last edited by a moderator: