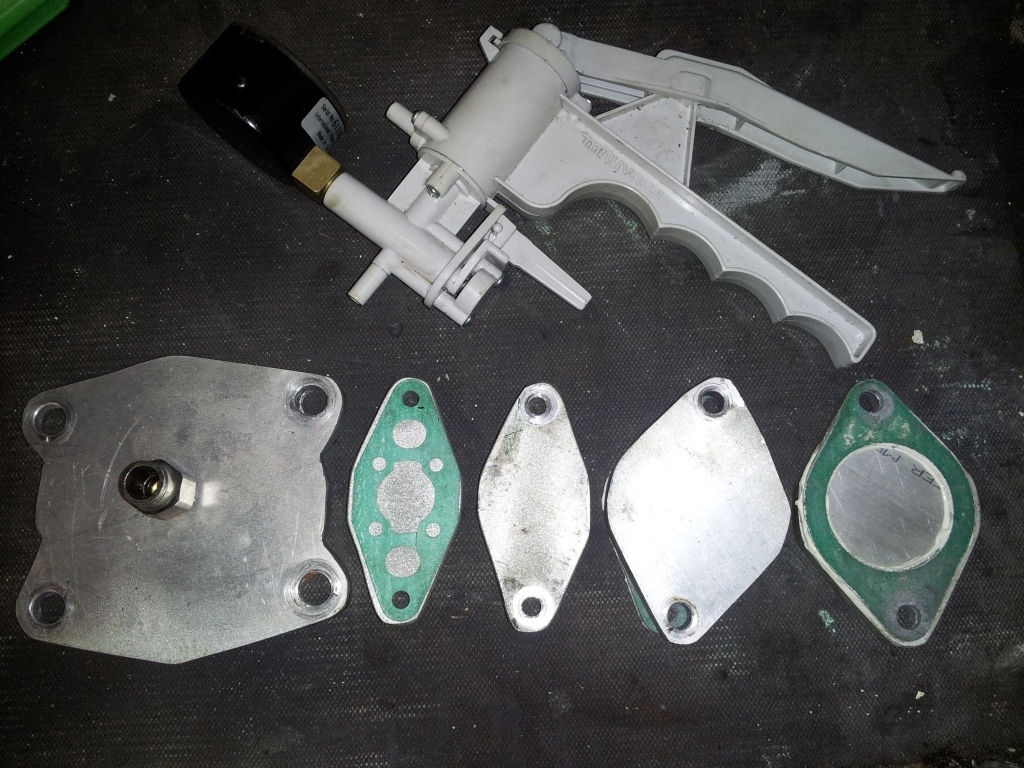

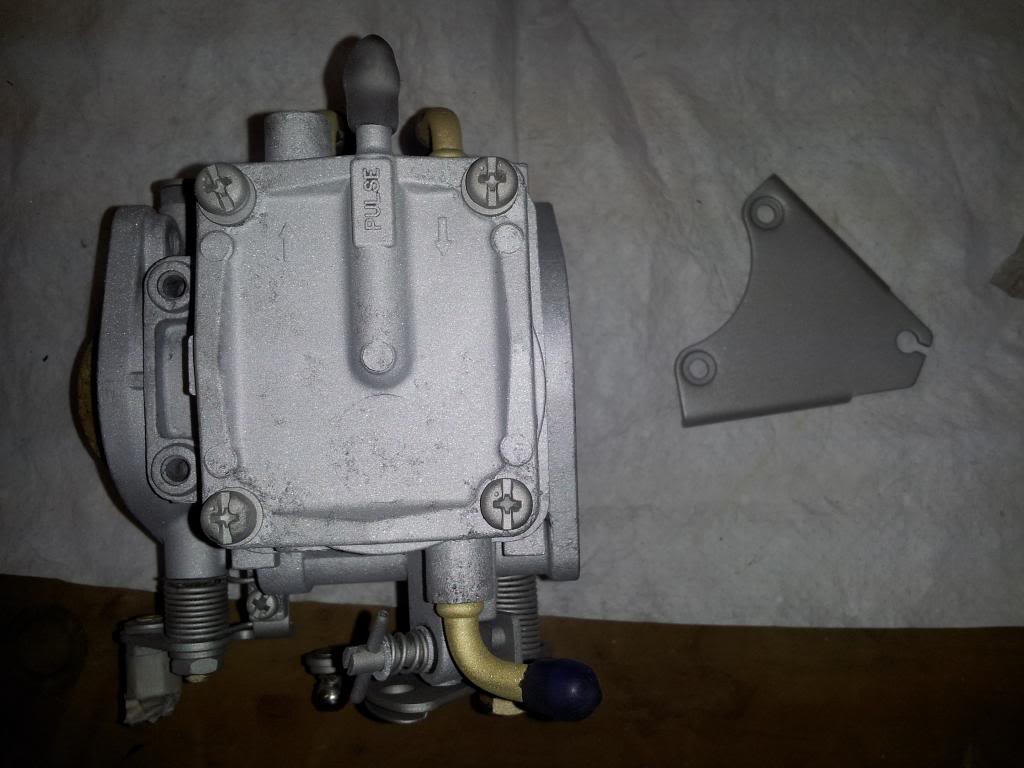

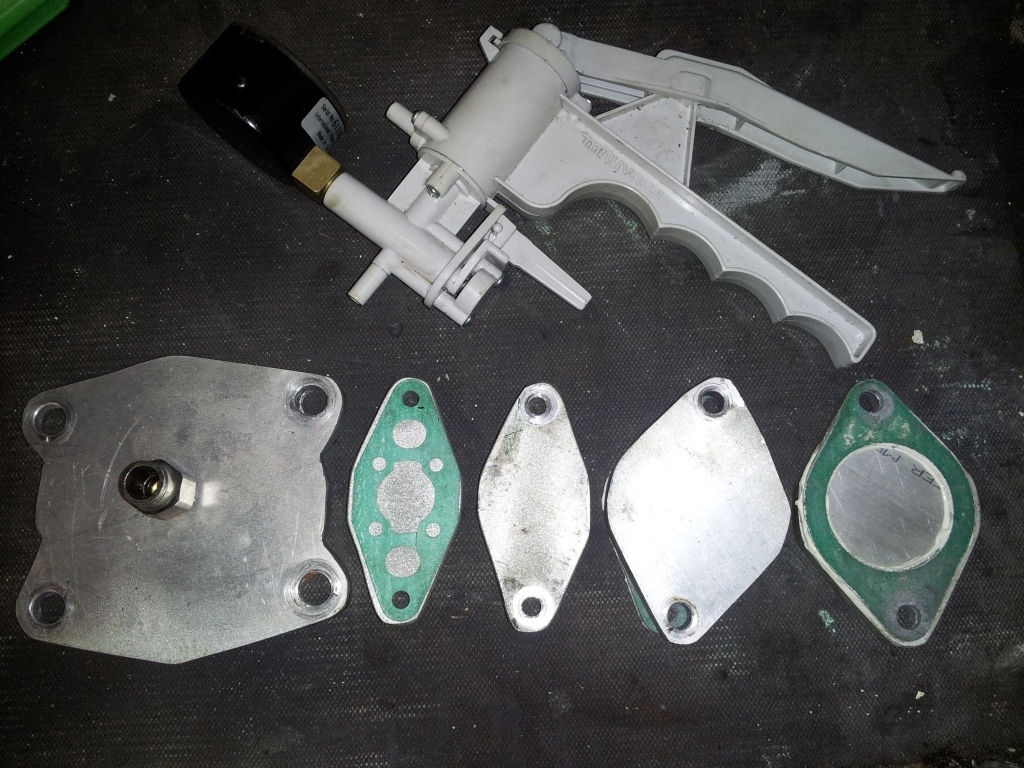

Ok, so some of you guys have commented about my pressure testing kit. This kit is mimicked off the kit that Bombardier has shown in their service manual. I use this to pre-test the engine BEFORE and AFTER a rebuild. I use it before to check for any internal leaks that could pop up from say a bad winterizing job and cracked a cylinder jacket etc... You can check several areas on the 787. You can check the Rotary Valve seals, engine cooling passages and the top end and the bottom end. The procedure and flow chart is in the service manual. I tried using rubber for gaskets, they didn't work very well so I prefer to use OEM gaskets. I use hi-temp RTV on the exhaust portions of the kit and on both sides of the gaskets and for the carb flange gaskets I use gaskets from a Speedster jet boat (204250035), they measure almost .125 thick(real thick) compared to .021 for a ski I use Threebond 1211 on them. When I test I use the Mityvac hand pump, you can get them at auto parts stores and harbor freight (http://www.harborfreight.com/mityvac-vacuum-pump-39522.html), I run this through a 1/4" ball valve available at Home Depot, Lowes, or plumbing supply store, and I have the valve inline so when I reach 5 psi I close the ball valve, just to eliminate any leaking that could come from the hand pump. You can also use an air compressor--BUT REGULATE IT DOWN TO 5 PSI, this will save you on needing the hand pump. You can make a soap/water solution to spray on the engine and watch for air bubbles to find your external leak, the internal leaks are covered in the manual. In the following picture is what you will receive EXCEPT the fitting, the Hand pump and gaskets, you're only getting the block off plates. You'll get two RAVE block offs, two CARB block offs, and one Head Pipe block off all made from 3/8" thick aluminum. I also use vacuum plugs that are available at your local auto parts store, I use them for the oil injection nipples, fuel pump pulse line, water cooling fittings and finally the Rotary Valve in/out fittings. I use push to connect fittings designed for air lines, we use them at work for our equipment. You'll need to come up with an adapter for what ever size lines you'll use. I could provide all this but it will take the price too high, so I'm keeping this kit to the basic plates and you can be resourceful to gather the rest and cobble with what you have. I will be glad to answer ANY questions you might have to get you started.

Now to the nitty gritty. The kits will be $65.00 plus shipping. I'll work this two ways, I'll gladly ship via USPS and will get you the shipping charges BEFORE you pay OR if you have your own UPS account I'll gladly ship using your account and have it bill direct to you. I do not charge more than what I get charged and no handling fees. I try to keep from using the USPS boxes as they are charging you for them--they're NOT FREE, the flat fee is usually more than what I can ship it for using a box I supply/recycle--I try to keep everything on the cheap, so how ever get it there cheaper is how it will go. I typically ship USPS Priority Mail. I will ship North of the border, EH!

So to start I'm getting these made in quantities of 5, so I'll have the first 5 made once five guys post up they want a set. I really don't want to go too far out on the line for these as I'm not sure how many are interested. The current delivery is 3 to 4 weeks, the water jet runs non stop all day so they have to "fit" me in. I'm not pulling down mega bucks making these, by the time Paypal gets their cut, my time to get them, pack them and ship them it's just about a wash on what I'm paying for them. I'm just doing it for the fun of the hobby to be honest, I have a full time business and it does not revolve around boating. I do service work and travel so there may be times I'm not around to possibly ship, but can usually figure something out and can respond.

Attn Mods, if this is in the wrong section feel free to move it.

Now to the nitty gritty. The kits will be $65.00 plus shipping. I'll work this two ways, I'll gladly ship via USPS and will get you the shipping charges BEFORE you pay OR if you have your own UPS account I'll gladly ship using your account and have it bill direct to you. I do not charge more than what I get charged and no handling fees. I try to keep from using the USPS boxes as they are charging you for them--they're NOT FREE, the flat fee is usually more than what I can ship it for using a box I supply/recycle--I try to keep everything on the cheap, so how ever get it there cheaper is how it will go. I typically ship USPS Priority Mail. I will ship North of the border, EH!

So to start I'm getting these made in quantities of 5, so I'll have the first 5 made once five guys post up they want a set. I really don't want to go too far out on the line for these as I'm not sure how many are interested. The current delivery is 3 to 4 weeks, the water jet runs non stop all day so they have to "fit" me in. I'm not pulling down mega bucks making these, by the time Paypal gets their cut, my time to get them, pack them and ship them it's just about a wash on what I'm paying for them. I'm just doing it for the fun of the hobby to be honest, I have a full time business and it does not revolve around boating. I do service work and travel so there may be times I'm not around to possibly ship, but can usually figure something out and can respond.

Attn Mods, if this is in the wrong section feel free to move it.