Sportster-2001-951C-Stock

Well-Known Member

Hi dennis that is exactly what i was talking about. I believe I found the right spot. is it the little red screw in pic?

Also as you guys have stated, yes i want to narrow it down and find the cause of the oil pressure signal before worrying about compression. I am bringing the ski to a car shop tomorrow to borrow the oil pressure tester. I will see what I find then. Also how do I check the oil screens youve mentioned? Are you talking about the oil filter or is there something else?

Assuming there's enough room to leave a gauge mounted on the head, you could just buy an 100psi gauge and whatever fittings necessary, maybe 1/8" pipethread or metric? I'm not sure. Screw the gauge right into the head and leave it there permanently for future use?

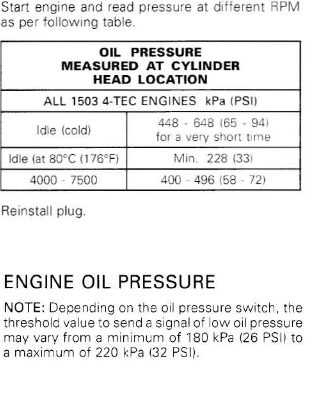

The reason I'm suggesting this is it's always nice to have a way to monitor the engine OP occasionally to get an idea if something's a-okay or not, and oil pressure ordinarily drops considerably as the engine and oil heats up, which can't be simulated on the trailer. You might have a good 50psi idling cold and that could drop to 5psi hot, hopefully not less than 10~15psi, general rule of thumb is 10psi for every 1000rpm hot oil.

I would of course prefer a lower psi gauge because the accuracy would be better at lower hot idle pressures but I don't know what maximum OP to anticipate with this particular motor. Say for instance normal OP at idle with hot oil is 50psi, and at WOT is 150psi, the 100psi gauge would be inappropriate. Typically, I see about 60psi cold oil max pressure and idle around 15psi hot, that's usually enough for a healthy engine.

So, 100psi gauge would be too large in that case, an 60 or 80psi gauge will give a better read at hot idle conditions.

Gauge needle should not pulsate up and down as RPM is held steady, a pulsating needle indicates a leak emerges at a certain crank position.

Last edited by a moderator: