ParamedicCurt

New Member

Here's the situation:

2003 GTX-DI (Rotax 951) with only 86 hours. It had low compression, bad fuel pump and bad air compressor.

New WSM top end - 128 and 119 compression now

New WSM air compressor - good compression now

New fuel pump - good fuel flowing to the rail now

The fuel rail has been cleaned. All the O-rings have been greased and feel good and tight.

No error codes

Had a spare set of injectors so I swapped injectors - it ran for about 20 seconds (just twice) very rough. No throttle control

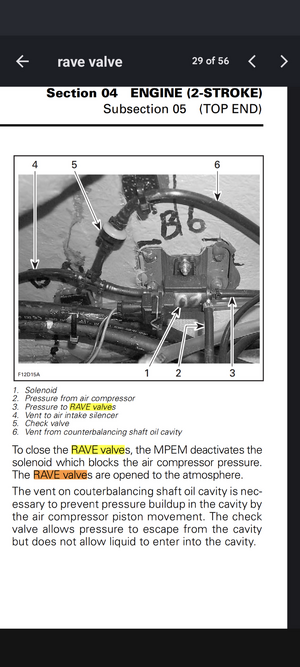

Cleaned the check valve and solenoid (they didn't appear to be dirty inside)

New spark plugs, properly gapped

New Battery

No large draw on battery when cranking

After ALL that, it still won't start. I even checked to see if there are codes that aren't triggering a maintenance light. There are none according to the display. The best result is when I changed injectors. It acts like it wants to fire, but just doesn't.

Could it be an ignition coil? I went to Harbor Freight tonight to get an in-line tester and they closed 4 minutes before.

Should I try replacing the check valve and solenoid?

Could there be something in the MPEM that needs to be reset? On YouTube I saw the Seadoo Refurb guy from Canada use Can-doo Pro on the same year ski reset something (after doing a complete rebuild) and it fired right up. How much would a repair place charge to do that?

I'm determined now to not let this thing beat me!

I'm very vested now.

- New handle bar grips installed

- New deck mats installed

- New bearings, couplers and tires installed

- All the waxes and pads to take the oxidation off the hull and refresh all the black plastics

- Heat gun and Goo Gone to get the old ugly stickers off

Any ideas?

2003 GTX-DI (Rotax 951) with only 86 hours. It had low compression, bad fuel pump and bad air compressor.

New WSM top end - 128 and 119 compression now

New WSM air compressor - good compression now

New fuel pump - good fuel flowing to the rail now

The fuel rail has been cleaned. All the O-rings have been greased and feel good and tight.

No error codes

Had a spare set of injectors so I swapped injectors - it ran for about 20 seconds (just twice) very rough. No throttle control

Cleaned the check valve and solenoid (they didn't appear to be dirty inside)

New spark plugs, properly gapped

New Battery

No large draw on battery when cranking

After ALL that, it still won't start. I even checked to see if there are codes that aren't triggering a maintenance light. There are none according to the display. The best result is when I changed injectors. It acts like it wants to fire, but just doesn't.

Could it be an ignition coil? I went to Harbor Freight tonight to get an in-line tester and they closed 4 minutes before.

Should I try replacing the check valve and solenoid?

Could there be something in the MPEM that needs to be reset? On YouTube I saw the Seadoo Refurb guy from Canada use Can-doo Pro on the same year ski reset something (after doing a complete rebuild) and it fired right up. How much would a repair place charge to do that?

I'm determined now to not let this thing beat me!

I'm very vested now.

- New handle bar grips installed

- New deck mats installed

- New bearings, couplers and tires installed

- All the waxes and pads to take the oxidation off the hull and refresh all the black plastics

- Heat gun and Goo Gone to get the old ugly stickers off

Any ideas?

Attachments

Last edited: