Not trying to argue, just throwing thoughts out there. We know so little in how the MPEM actually internally is designed and works. And yes, the manual says that the memory of the MPEM is permanent, but how? Computers don't work that way and that's what the MPEM is -- a mini computer. What if the memory is permanent under certain conditions; whereas we're using these machines under an unlimited set of unexpected and tested variables. What if no one at Bombardier ever expected a seadoo to last 21 years and kill that battery they assumed never needed to be replaced and/or charged?

In thinking through all of this, I started googling a bit.

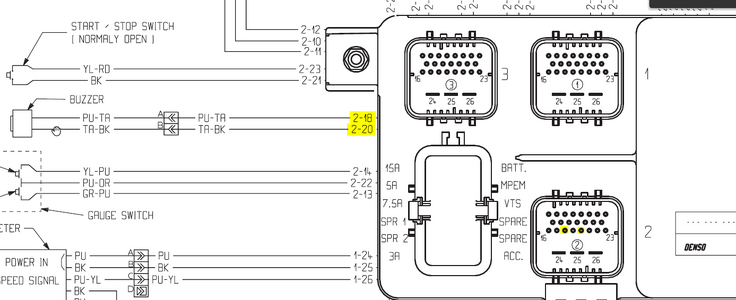

In other forums I found information on MPEM battery pull even with no key on the DESS post. So then I started thinking further...why would the MPEM pull power from the battery without key. Why would it need that?

I do IT for a living, and every computer has a CR2032 or CR2025 battery which stores and retains Basic Input Output System (BIOS) information. Your date and time, CPU information, boot device, TPM, etc settings which are required before the computer boots into your operating system (Windows, Linux, in the case of apple privitized Unix). Those batteries are about 2.4V - 3.0V. When that replaceable battery goes dead, it loses all of it's settings within the BIOS, and even the date will return to the original MFG date any time the computer is unplugged from power. So, what if, on our Seadoos, the MPEM requires power to retain settings, i.e., keys, etc.. On computers, BIOS settings are considered permanent as well -- defaults are permanent, modifications and changes to those non-default settings are not. Remember, the factory does not program your keys. In fact, I am told that the MPEM's don't even come installed within the machines when they are shipped anymore, and this is something the dealer must do to prep the ski.

Furthermore, what if there is a little onboard rechargeable battery within the MPEM, (or capacitor) that retains enough power to retain key programming, etc. which requires power and/or recharging. So when a "starting/running" battery hasn't been installed for long periods of time, like in my case 7 years, and we install a battery, it starts to recharge the MPEM. The 2.4V - 3.0V loss would make sense if that was what was required to recharge the MPEM.

More info on capacitors:

if the power supply is removed or disconnected, the capacitor can supply its stored charge into the circuit. In this way, the capacitor acts like a small battery. This energy-storing property of a capacitor is called its capacitance, and is usually measured in Farad.

In other words, a capacitor can be gradually charged to reach the required voltage level to provide the energy needed by an electronic device. Since 1 farad is a very high value, capacitors used in electronics usually contain capacitances measured in picofarads, nanofarads, microfarads, and millifarads. A charged capacitor left unused can retain its charge for a long time, even years.

Capacitors are crucial components in so many electronic devices such as household appliances, handheld devices like smartphones, and computers. The main function of a capacitor in these devices is to store electrical energy to facilitate their operation in diverse ways. Thus capacitors can be used to provide different types of electronic filtering, as well as provide a means to store and discharge energy.

It is pertinent to note that if a fully charged capacitor is not discharged in the circuit, it can retain the charge even when the main power supply is disconnected. Therefore, extreme caution is required when working with capacitors in general.

Very good capacitors lose internal charge after 10,000 hours, and over the course of 7 years, that would be 61,320 hours.

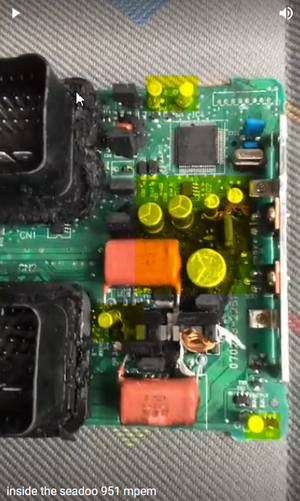

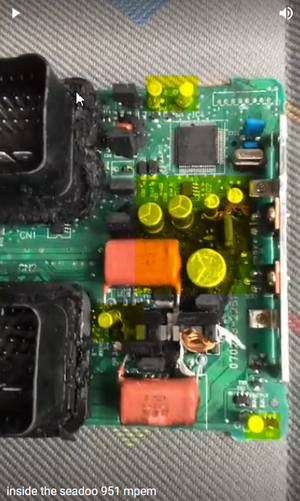

So I did some digging about what is inside the 951 MPEM, and found this....everything highlighted appears to be a capacitor. That's a lot of capacitors to recharge.

So maybe no one at seadoo thought 1) a ski would last that long and 2) no one would certainly have a battery disconeccted that long.

Don't get me wrong, I have listened to the advice here and I am replacing the battery - they are sending a new one to replace the brand new one. However, in thinking through all of this, it seems odd the battery would drop down to 10.9V, then pop back up to 12.7 (which is a 2.4 - 3.0V difference).

So far, the battery does not seem to lose power after being charged and sitting not installed. I charged it over night and am letting it sit for a day to re-verify this observation.

Yesterday when I took it to be checked, I removed it directly from the ski and did not charge, so of course it would have low reserve.