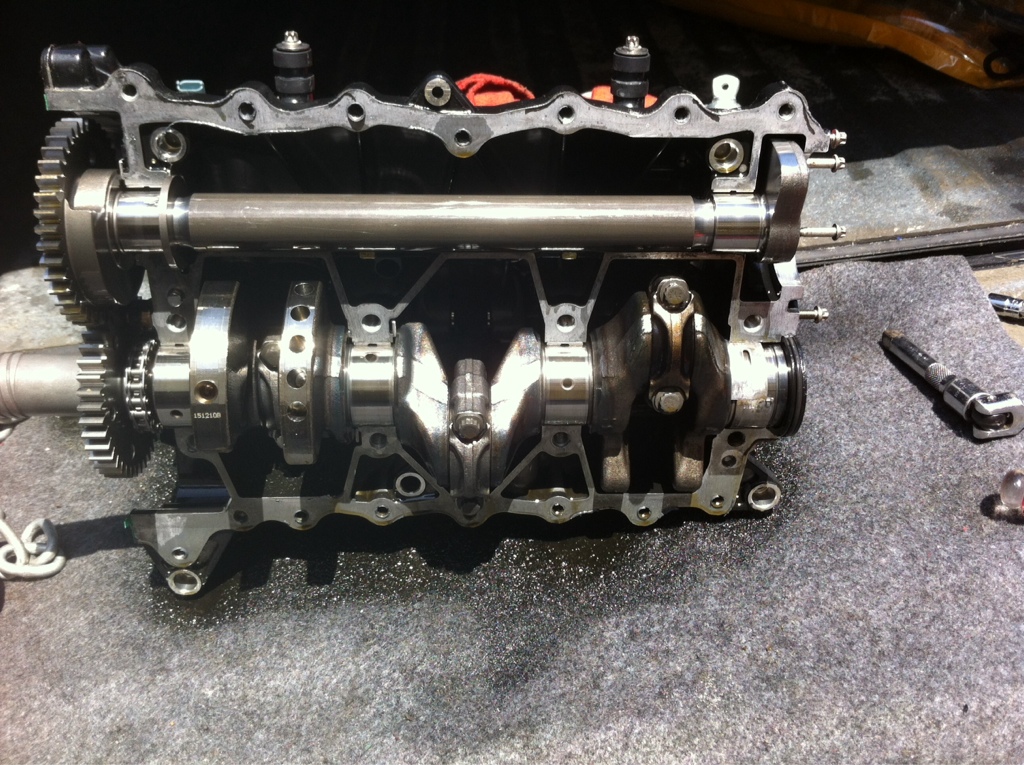

I recently purchased a 2008 RXP-X with an engine noise for a deal that I couldn't turn down. I have checked the Supercharger which is in good shape, pulled the valve cover and no broken rockers, and pulled the pump to make sure the noise was in the engine as expected it still was. I figured it to be a rod knock from the little that I had heard it, but wanted to try a few things to make sure. So now I am at the point were I need to make up my mind if I want to rebuild or buy an SBT drop in. I think the damage is limited, as there no shavings in the oil. I am more than likely looking at a new rod, new crank, new rod and main bearings as well as stretch bolts and gaskets. The ski only has 39 hours on it, and when I pulled the rocker cover it was super clean. I am an automotive mechanic and have no problems doing the work, but I am just wondering if it would be worth it to rebuild over the slightly higher cost for an SBT drop in. Any thoughts or suggestions would be welcome.

Also, or these engines prone to rod bearing failure, and should I look at ARP Rod bolts and a hone for the rods based on the ARP bolt's added clamping force?

Just want a stock ski but fix any issues that might cause a future failure while I am at it.

Kurtis

Also, or these engines prone to rod bearing failure, and should I look at ARP Rod bolts and a hone for the rods based on the ARP bolt's added clamping force?

Just want a stock ski but fix any issues that might cause a future failure while I am at it.

Kurtis