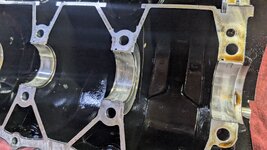

As the thread title says, the middle cylinder doesn't seem to be firing. It is getting gas and spark to all cylinders. Compression on cylinders 1&3 are right at 140, but the middle cylinder is 120ish. That's obviously not ideal, but I wouldn't think it is low enough to keep it from firing all together..........Or is it?

The other symptoms are as follows:

The beeper works, but is intermittent. The beeper itself tests out ok when hit with 12 volts.

The red LED flashes and the screen displays check engine. That is consistent.

It throws random codes with p0344(CAM) & p1200(TOPS) being the most consistent. But random enough that I not sure I should trust anything it says.

The random codes makes me wonder if its a bad ECU, but I'm not sure if that would also cause one cylinder to completely misfire or show low compression. Unfortunately, I don't have another ECU, nor do I have BUDS or CANDOO. Other than swapping out the ECU, is there a way to definitively test it?

I guess I'm just wondering what my next course of action should be??? I'm no jet-ski mechanic, but I do want to learn, so any insight or suggestions would be greatly appreciated.

The other symptoms are as follows:

The beeper works, but is intermittent. The beeper itself tests out ok when hit with 12 volts.

The red LED flashes and the screen displays check engine. That is consistent.

It throws random codes with p0344(CAM) & p1200(TOPS) being the most consistent. But random enough that I not sure I should trust anything it says.

The random codes makes me wonder if its a bad ECU, but I'm not sure if that would also cause one cylinder to completely misfire or show low compression. Unfortunately, I don't have another ECU, nor do I have BUDS or CANDOO. Other than swapping out the ECU, is there a way to definitively test it?

I guess I'm just wondering what my next course of action should be??? I'm no jet-ski mechanic, but I do want to learn, so any insight or suggestions would be greatly appreciated.