Krispy

Well-Known Member

So this past weekend I took my new to me ski out for sea trials, all was successful except I had my engine idle set too low.

In the water it was idling about 1000 rpm. At this RPM the engine would shake a bit, much like having a large "Cam" in a car. At these idle speeds there was a knocking against the hull that I couldn't identify. This knocking went away at about 1500 rpm.

This is something that I can't reproduce on the hose as the engine speed is much greater than 1500 without load on the pump.

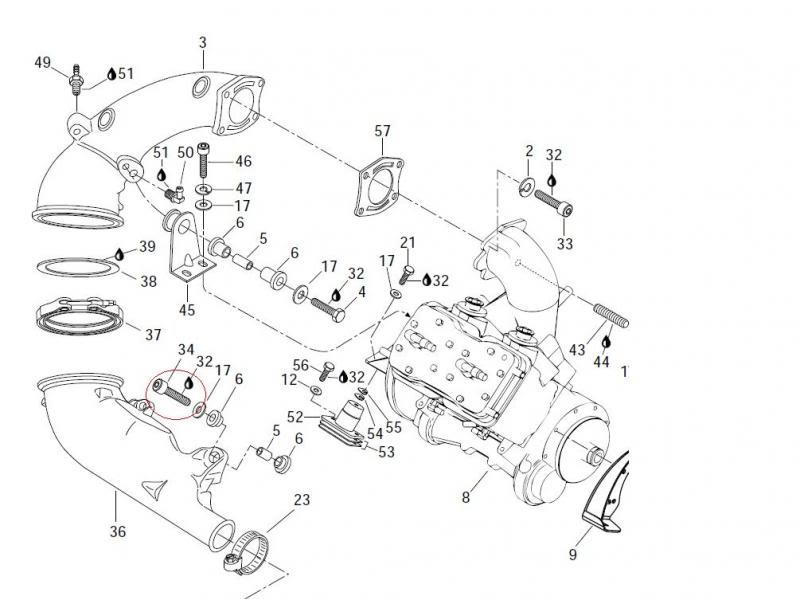

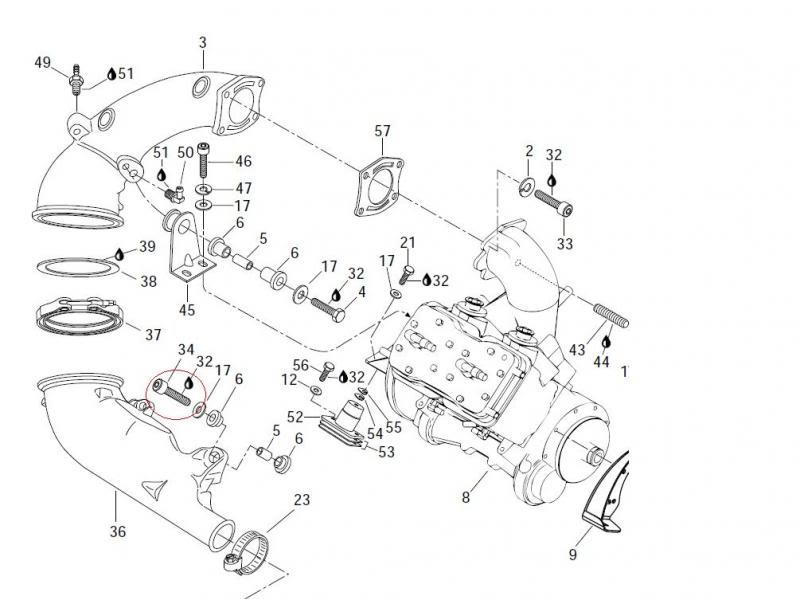

I checked all the engine mounting bolts, all are tight. I did however find the bolt that wasn't fully seated (circled in red).

It appears to be cross threaded slightly into the engine and I can't seem to access it with any of my tools with enough torque to back it off. Any suggestions?

Could this be the cause of the problem?

When I tug on the engine and exhaust nothing seems to contact the hull. But something sure is makcing a racket at these low idle speeds.

Check the Youtube Video.

[video=youtube;n9Svh1z5rFs]http://www.youtube.com/watch?v=n9Svh1z5rFs[/video]

The Youtube video is still uploading but should be online shortly...

In the water it was idling about 1000 rpm. At this RPM the engine would shake a bit, much like having a large "Cam" in a car. At these idle speeds there was a knocking against the hull that I couldn't identify. This knocking went away at about 1500 rpm.

This is something that I can't reproduce on the hose as the engine speed is much greater than 1500 without load on the pump.

I checked all the engine mounting bolts, all are tight. I did however find the bolt that wasn't fully seated (circled in red).

It appears to be cross threaded slightly into the engine and I can't seem to access it with any of my tools with enough torque to back it off. Any suggestions?

Could this be the cause of the problem?

When I tug on the engine and exhaust nothing seems to contact the hull. But something sure is makcing a racket at these low idle speeds.

Check the Youtube Video.

[video=youtube;n9Svh1z5rFs]http://www.youtube.com/watch?v=n9Svh1z5rFs[/video]

The Youtube video is still uploading but should be online shortly...