WaterChampion

Member

Hi,

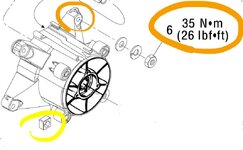

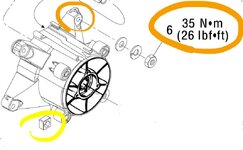

I’ve done several pump replacements on 96 Seadoo GTI’s and I’m not sure if I should follow the manuals stated torque specs. It always seems like it’s too much. As you can see here from the photo, with it set to the proper torque, it has squished the plastic downwards so far I’m surprised it didn’t crack. This has happened on two Seadoos that I’ve done. Also the little square plastic washer backing nuts for the stacked shroud end up deforming and trying to rip the plastic when set to the specified torque. I’ve check the torque wrench on several other things and got a perfect click but on this it just keeps going, never achieving torque. Is it because the plastic is 30 years old? At this point I think I should just tighten them with some “umph” and call it done? It’s also interesting to me why this doesn’t call for LT 242…

Thoughts?

I’ve done several pump replacements on 96 Seadoo GTI’s and I’m not sure if I should follow the manuals stated torque specs. It always seems like it’s too much. As you can see here from the photo, with it set to the proper torque, it has squished the plastic downwards so far I’m surprised it didn’t crack. This has happened on two Seadoos that I’ve done. Also the little square plastic washer backing nuts for the stacked shroud end up deforming and trying to rip the plastic when set to the specified torque. I’ve check the torque wrench on several other things and got a perfect click but on this it just keeps going, never achieving torque. Is it because the plastic is 30 years old? At this point I think I should just tighten them with some “umph” and call it done? It’s also interesting to me why this doesn’t call for LT 242…

Thoughts?