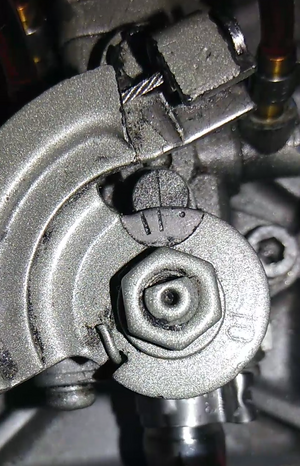

Just installed this engine and have 1/2 run time. Head gasket was leaking so I pulled the head and saw these marks on both pistons. I also had a film of fresh oil on the combustion areas of the head. I suspected that I had too much oil with the wrong setting on the pump which I didn't reset during the rebuild. Setting marks were lined up only problem is there are TWO marks.  I did some checking in the repair manual and the pump adjustment is "spot on" where it should be. These pictures are 1/2 hour run time mostly idle to 2500 RPM in the water. 1st break in. This may be normal which I will gladly accept. Plugs looked a little dark but that's to be expected at idle for long periods and all the pump oil coming in.

I did some checking in the repair manual and the pump adjustment is "spot on" where it should be. These pictures are 1/2 hour run time mostly idle to 2500 RPM in the water. 1st break in. This may be normal which I will gladly accept. Plugs looked a little dark but that's to be expected at idle for long periods and all the pump oil coming in.

Engine was a sluggish coming off idle which leads me to thin it is over oiling. I'm gonna take pressure tests for fuel and air and may run diagnostics with the Candoo just to be sure.

This was after I wiped the piston with a rag.

Engine was a sluggish coming off idle which leads me to thin it is over oiling. I'm gonna take pressure tests for fuel and air and may run diagnostics with the Candoo just to be sure.

This was after I wiped the piston with a rag.