justinb

Active Member

Hi All

I recently did a bottom end replacement of crank seals and bearing the whole 100 yards

Same time I did the top end , I bought new piston and rings standard size as nothing was damaged on cylinder head I bought SBT ones,i was told I only needed to hone the heads which I got an engineering firm to do with the pistons and rings so they could measure all up .

I now recently tried starting but the one head had 90 psi, after striping it apart I noted the top ring had a big gap I then adjusted the ring .

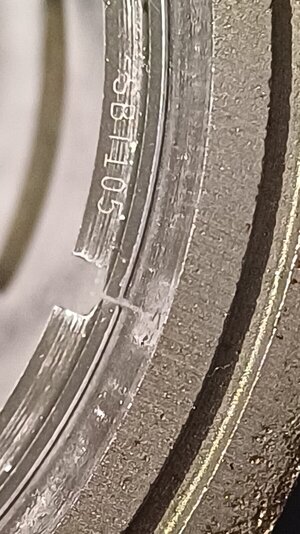

See first pic which has the ring in cylinder showing the ring gap , I belive this is in spec with SBT chart 0.05

Now look at the 2nd pic around the red circle the ring in this space is not sitting flush against the wall it has about a 0.002 space

Does this mean anything? In the 3rd pic with the piston on and in the sleeve I can't get a 0.002 in it any more .

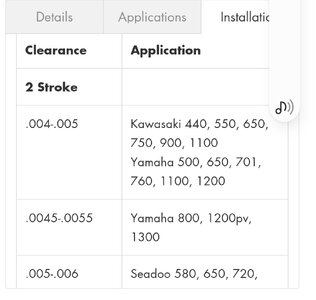

However the SBT chart says I should have 0.005 clearnce

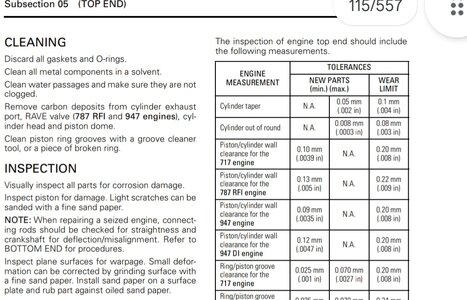

In the book seadoo book it says 0.001 which I don't have that side feeler gauge but it if look at the 0.002 I think it would fit if I had it .

Which should I be going off if I am using SBT rings and pistons or the book ?

The last 2 pictures are the inside of my cylinder

Thanks I don't know if it will work as is or do I need to have the cylinder wall honed deeper to fit the tolerances of the SBT rings and pistons

Or after riding it in this will change ?

Thanks

I recently did a bottom end replacement of crank seals and bearing the whole 100 yards

Same time I did the top end , I bought new piston and rings standard size as nothing was damaged on cylinder head I bought SBT ones,i was told I only needed to hone the heads which I got an engineering firm to do with the pistons and rings so they could measure all up .

I now recently tried starting but the one head had 90 psi, after striping it apart I noted the top ring had a big gap I then adjusted the ring .

See first pic which has the ring in cylinder showing the ring gap , I belive this is in spec with SBT chart 0.05

Now look at the 2nd pic around the red circle the ring in this space is not sitting flush against the wall it has about a 0.002 space

Does this mean anything? In the 3rd pic with the piston on and in the sleeve I can't get a 0.002 in it any more .

However the SBT chart says I should have 0.005 clearnce

In the book seadoo book it says 0.001 which I don't have that side feeler gauge but it if look at the 0.002 I think it would fit if I had it .

Which should I be going off if I am using SBT rings and pistons or the book ?

The last 2 pictures are the inside of my cylinder

Thanks I don't know if it will work as is or do I need to have the cylinder wall honed deeper to fit the tolerances of the SBT rings and pistons

Or after riding it in this will change ?

Thanks