OK... let's start with the alignment. It doesn't matter if the mounts were left in the hull, since the adjustment is made between the mount, and the belly pan of the engine. (pressed steel plate)

Once you get the engine into the hull... leave it loose, and if you had old shims, do not put them back in. (but remember where they were) Then put your alignment tool in the pump hole, and see if it freely slides into the PTO. Adjust the shims as needed to make it a zero pressure slip fit. Take your time since a miss alignment can bend the driveshaft, or eat the splines out of the PTO. It's not hard, but make sure things are straight.

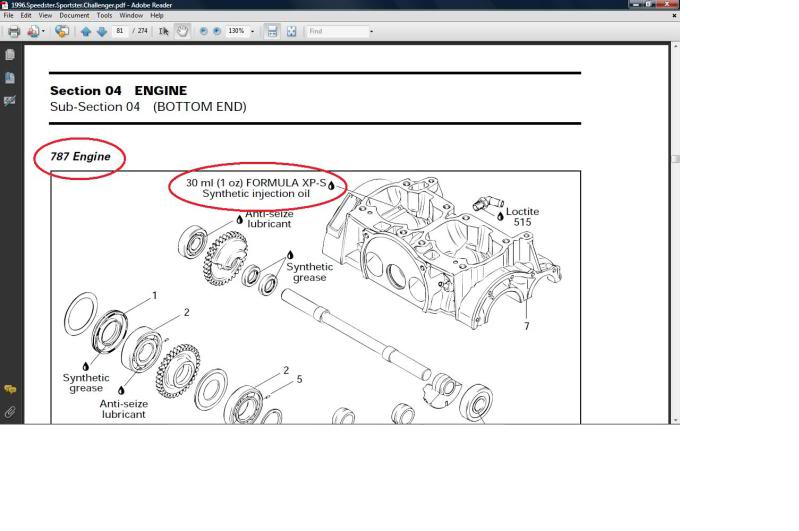

Next... the oil system.

I'm glad you are going to leave the oil injector in the engine. The Rotax/Mikuni oil pump is very reliable, and they almost never fail, BUT... the supporting parts can fail. Most of the time when we see someone say that their "Oil system failed"... it is plugged up, or the hoses fell off because no one ever serviced it. So... I would replace all of the hoses in the oil system. You don't need to replace the metal crimp clamps on the small hoses... just put them on with a good quality zip-tie. If there is a question about the quality... don't use them. You don't want to loose an engine because a dollar store zip-tire failed.

Also, there is an oil filter on the hose feeding the pump. replace it. And... the little hose nipples on the intake manifold are known to plug up over the years... while the hoses are off... make sure they are clear. (push some wire thought them)

On the pump there is a couple check valves, held on with a banjo bolt. Take them off, and clean them with a shot of carb cleaner. (they are the outlet of the pump)

If there is any reason to think that your pump is bad... you can check it while it's off the engine. (it tells how in the manual, and how much oil it should pump over a given time)

Next is the rotary valve...

Don't assume that the front of the valve will remain the front on your new engine. The internal rotary valve gears don't have a set position, so... if you put the valve on your engine, and it doesn't seem quite right... flip it over. Here again, take your time when setting the rotary valve timing. We see it all the time here where someone get's the new engine in the hull, but it won't run right, and after days of BS'ing... they finally take the manifold off, and recheck the valve. It's much easier to do it right the first time. Oh... and you don't have to go out and buy a Rotax degree wheel. Somewhere there is a simple one you can print out, and use it one time. (I've used a paper one a bunch of times)

Since everything is apart... it's a good time to clean the carbs, and fuel filter if you think there were problems with them.

After everything is back in, and hooked up... check these things before starting...

1) are all the oil hoses hooked up?

2) are all the cooling hoses hooked up. (including the one under the exht manifold)

3) do you have clean, approved oil in the oil tank?

4) add 2 oz of oil, per gallon of fuel to the main oil tank, for at least one full tank. (unless you have a Di engine, and I like to go 2 tanks for a ski) This helps with the break-in since the engine will run a little hot until the rings seat.

5) don't forget to bleed the oil system, and adjust the cable so you get the proper amount of oil.

Once that is all done, and you have test fired it in your shop/garage... go to the lake, and put it in, but leave it on the trailer.

1) start it up, and make sure the oil is pumping, and adjust your idle. (1500 rpm)

2) look for any water leaks, and make sure water is pumping.

3) look for exhaust leaks.

4) make sure you have a nice crisp throttle response.

After all that... go ride, and have fun. (try not to run full throttle for more than a few seconds at a time, but don't baby it either)

If you did everything right... after you burn the fuel with the extra oil, put in a fresh set of plugs, and try not to hurt yourself. :cheers: