You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

02 RX DI Engine Rebuild

- Thread starter statikuz

- Start date

- Status

- Not open for further replies.

statikuz

Active Member

I followed the instructions in the shop manual - they're two different tests of two different systems, it even tells you to continue with testing the bottom end if the cooling system is leaking. Also the manual says 5 psi so that's what I did. I guess if they wanted it to be 8 they would have made it 8.

Anyway I wasn't offended at all, I've been pretty diligent with following the manual in most regards.

Anyway I wasn't offended at all, I've been pretty diligent with following the manual in most regards.

statikuz

Active Member

So yesterday the head gasket leaked while pressurizing via the cooling inlet and the engine tested OK, pressurizing via the exhaust manifold.

Today I sprayed the head gasket with a thin coat of copper spray and it seemed to seal up better this time, losing about a needle-width's of pressure over 3 minutes.

I re-tested the engine and found that one of the oil injection check valves leaks - I didn't catch it yesterday, I guess because it took that long for it to push the oil back through the pump and into the oil inlet line. It's pretty slow, maybe 0.5 psi over 3 minutes. I don't know what to do about that. I guess I can try and pull it out of the case but with my luck I'd break it off.

Then I decided to re-check the cooling system again, and now it leaks badly, both at the head gasket (between the layers) and the base gasket in one or two spots. I guess the next move is to take it down to the base gasket and try a little bit of 1211 on that, and try separating the layers of the head gasket and coating all the sides?

Today I sprayed the head gasket with a thin coat of copper spray and it seemed to seal up better this time, losing about a needle-width's of pressure over 3 minutes.

I re-tested the engine and found that one of the oil injection check valves leaks - I didn't catch it yesterday, I guess because it took that long for it to push the oil back through the pump and into the oil inlet line. It's pretty slow, maybe 0.5 psi over 3 minutes. I don't know what to do about that. I guess I can try and pull it out of the case but with my luck I'd break it off.

Then I decided to re-check the cooling system again, and now it leaks badly, both at the head gasket (between the layers) and the base gasket in one or two spots. I guess the next move is to take it down to the base gasket and try a little bit of 1211 on that, and try separating the layers of the head gasket and coating all the sides?

Last edited:

statikuz

Active Member

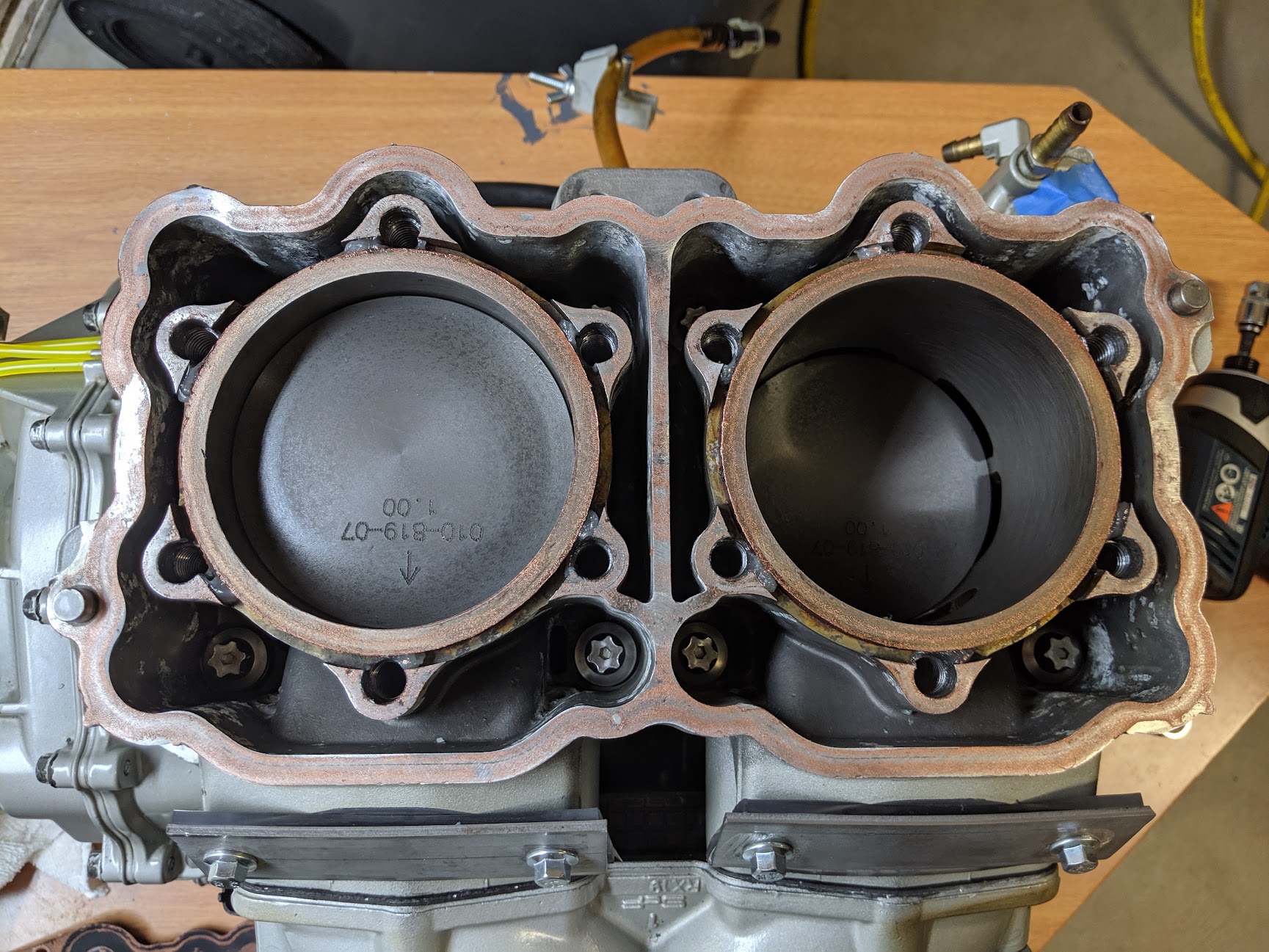

Here's some photos that might help. I think the head might just be pitted beyond saving. I had hoped it would be OK. It was mostly leaking on the left and right (fore and aft) sides, you can see where the copper didn't quite get smushed out. On the cooling inlet side it seemed to be leaking between the two layers of the gasket.

Any recommendations?

Any recommendations?

statikuz

Active Member

Alright, I was going to have the head resurfaced, there's no machine shops around here that do that sort of thing so I was going to send it out, but they said it was pitted too badly so I grabbed another on eBay that is in much better shape.

I unbolted the cylinders and gave the base gasket a very thin coat of 1211, bolted it back up (big zipties on the piston rings is the way to go), got an OEM head gasket, gave it a coat of spray copper, and I will try again tomorrow with the pressure test. I'm getting tired of having to clean those head bolts and reapply grease and Loctite every time.

I also found this thread on replacing the check valves; I had two leaking so I got some replacements (those ain't cheap) and will try this after testing.

injection oil check valve replacement

I unbolted the cylinders and gave the base gasket a very thin coat of 1211, bolted it back up (big zipties on the piston rings is the way to go), got an OEM head gasket, gave it a coat of spray copper, and I will try again tomorrow with the pressure test. I'm getting tired of having to clean those head bolts and reapply grease and Loctite every time.

I also found this thread on replacing the check valves; I had two leaking so I got some replacements (those ain't cheap) and will try this after testing.

injection oil check valve replacement

Before replacing the check valve on the DI I flushed the fitting a bit by pressurizing it with a Mitey Vac. First some cleaner then WD 40. It began working properly. I was told the check valves are Loctited in and should not be too difficult to remove. Perhaps a small amount of heat may be necessary.

statikuz

Active Member

Tested last night and both held 5 psi for 3 minutes per the manual so I quit screwing around with it. Looks like some combination of the new head, new OEM gasket, a bit of copper spray, and 1211 on the base gasket sealed it all up.

I re-primed the oil injection lines and watched them to see if any air was leaking back through the lines to the pump like it was before and I did not see that problem again, so I have decided against trying to replace the check valves.

I am going to hopefully get it back in the hull this weekend and aligned.

I re-primed the oil injection lines and watched them to see if any air was leaking back through the lines to the pump like it was before and I did not see that problem again, so I have decided against trying to replace the check valves.

I am going to hopefully get it back in the hull this weekend and aligned.

statikuz

Active Member

Got the engine back in (was able to borrow an engine hoist thank god) and aligned (that alignment tool is nice for $200). One of the pump mounting studs was stripped (who knows) so I had to replace that. Changed the pump oil and pressure tested it while it was out.

Putting the exhaust back in is the biggest chore - they give you that nice torque sequence which you can only kinda follow so that was a little frustrating.

Anyway, the only issue I ran into was greasing the PTO boot - it won't take any grease, it just squirts out around the fitting, could it be that the zerk fitting is gummed up? I tried to squirt a bit into my other ski and had the same problem so maybe its the grease gun?

gazzaskirepair

Active Member

You’ve done a good job and should fly across the water

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 89

- Replies

- 8

- Views

- 343