IDoSeaDoo

Well-Known Member

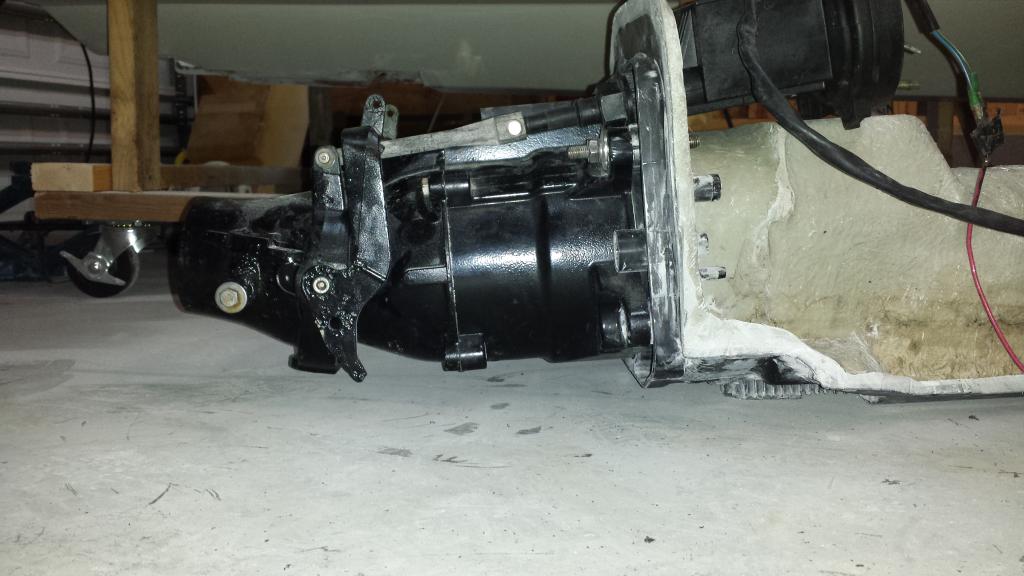

Here are some pics of the recent progress.

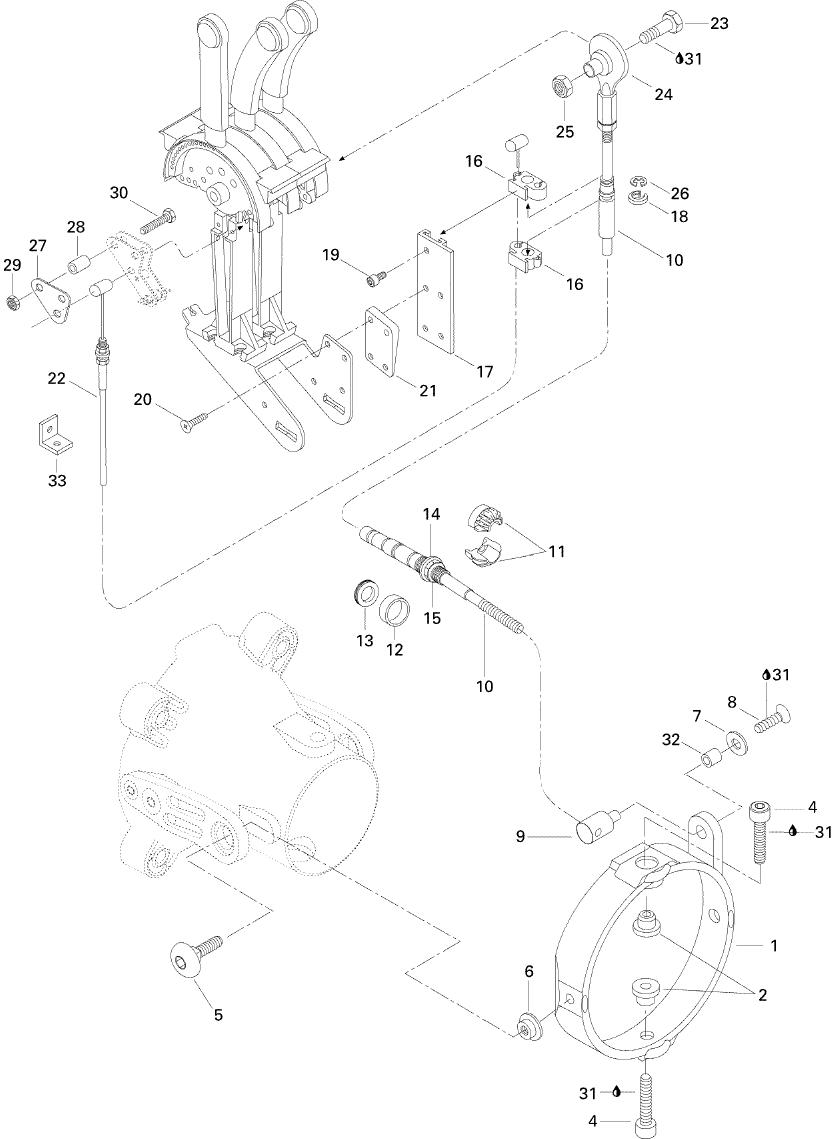

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]That's the section I cut out of the donor.

[/URL][/IMG]That's the section I cut out of the donor.

[/URL][/IMG]This a side-by-side of the old XP tunnel and the 4tec GTX tunnel. Everything GTX is larger

[/URL][/IMG]This a side-by-side of the old XP tunnel and the 4tec GTX tunnel. Everything GTX is larger

[/URL][/IMG]Here it is in the XP hull.

[/URL][/IMG]Here it is in the XP hull.

Here is the Cradle we built for her. Putting her in it was an interesting experience. Never really see boats just hovering above the ground Kind of a cool sight.

Kind of a cool sight.

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG] Too bad I didn't get it from the side!

[/URL][/IMG] Too bad I didn't get it from the side!

[/URL][/IMG]

[/URL][/IMG]

I can't imagine doing this without my awesome new respirator. It was my dad's xmas present to me. Seeing as how I'm getting more and more into these crazy sorts of projects, I need a good breathing device. The mask was okay, but this keeps it all out of my whole face. Thanks Dad!

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

[/URL][/IMG]

Here is the Cradle we built for her. Putting her in it was an interesting experience. Never really see boats just hovering above the ground

I can't imagine doing this without my awesome new respirator. It was my dad's xmas present to me. Seeing as how I'm getting more and more into these crazy sorts of projects, I need a good breathing device. The mask was okay, but this keeps it all out of my whole face. Thanks Dad!