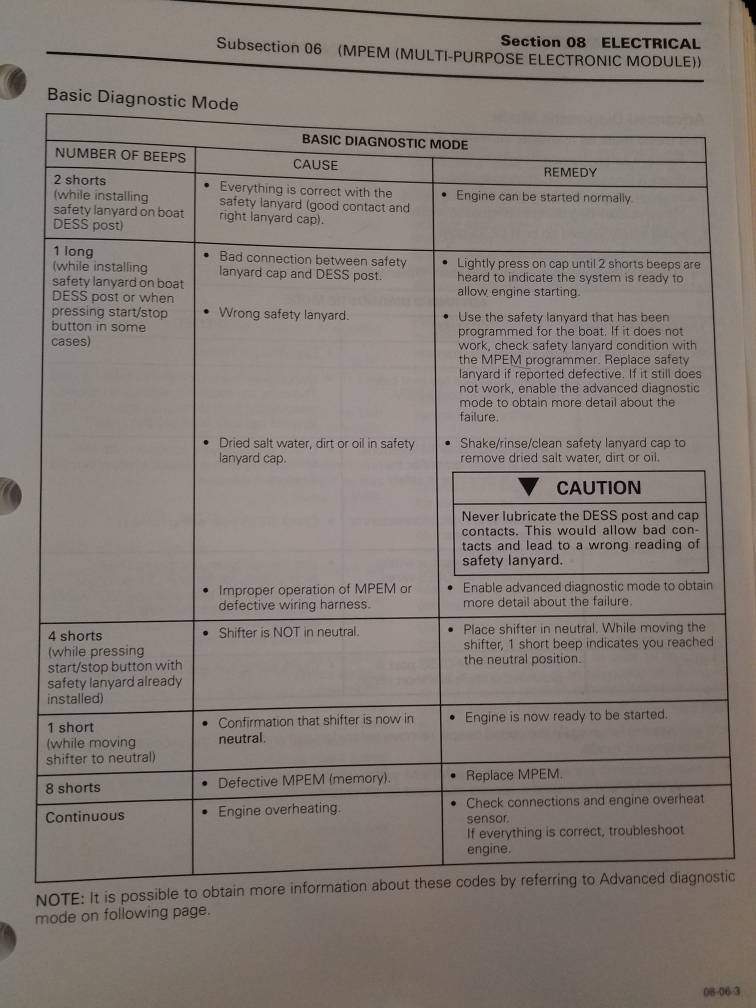

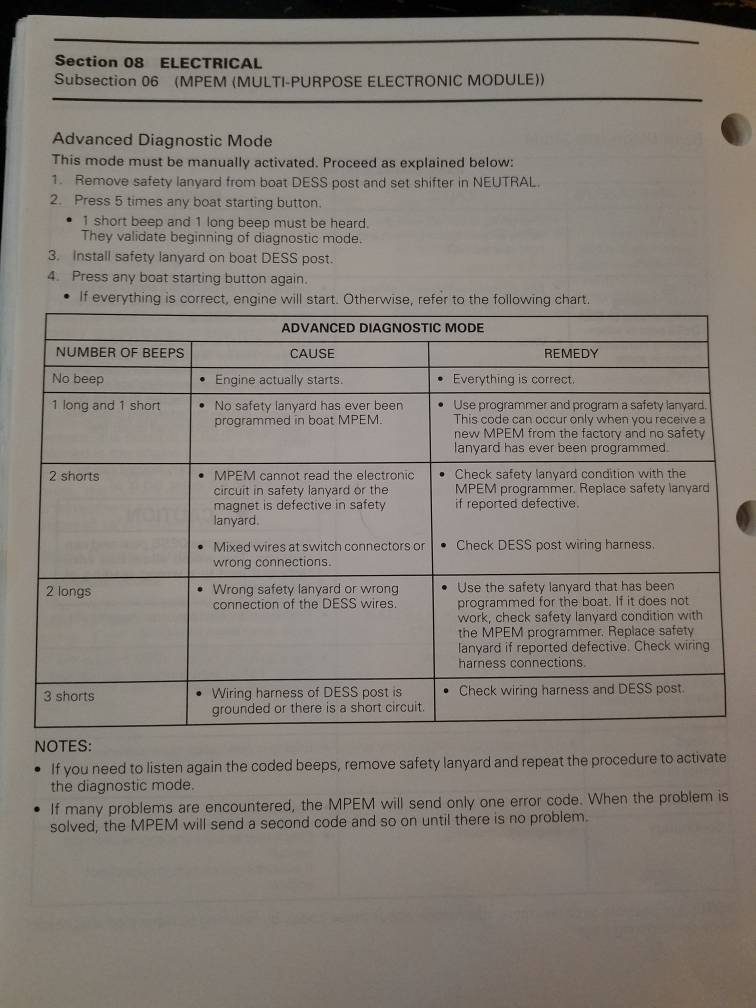

Okay, tried to follow all advice I received: cleaned up the terminal lugs, connected a battery with 13.8V and 200Ah, just to make sure I have plenty of power. Switched the battery switch to "on'', and pressed the starter button for the board-engine once - the rev-counter flickered once, can't tell if the gauges illuminated. Pressed starter button for starboard engine once - again rev-counter flickered once, only now for the starboard engine. No audible beeps. Then switched battery off, waited a few minutes, and turned back on again, and pressed board starter button five times - nothing, pressed starboard button five times -nothing. Disonnected battery, and checked the buzzer -dead, no wonder I didn't hear anything. Couldn't try a keyfob, since I don't have any yet. Reconnected battery, and checked circuits: Interior lights good, nav-lights and anchor light good, bilge pump good, fan circuit is good, but fan is dead, horn circuit good, but horn dead -after all not too bad. When I switch on the lights, the pilot light for the horn comes on, is that normal? The switch for the fuel is push-button, what does it do?

I found a dangling connector (2 core, black and green) behind the dashboard, does anybody know what that one is for?

On to the engine bay: Checked the MPEM visually, all fuses, terminals, overall condition, and it doesn't look to shabby. I found a bunch of connectors with caps and a busbar dangling roughly above the battery, what are they for? Once I have my Candoo, where does that get pugged into?

Connected a positive directly to the starter terminal with an in-line switch, and cranked the starboard engine until no fluid came out through the sparkplug holes - did many bursts about ten seconds, and then let the starter cool down again. Tried to test compression, got 110 at the Magneto side, and only 70 on the PTO side, but only because the starter didn't have enough strength to turn the engine over - the moment I took the tester off, it cranked over again pretty well, tester on, and it got stuck.

Tried the same with the board engine - starter spins, but doesn't engage, looks like the gear is seized and doesn't move forward.

Found massive corrosion holes at all welsch plugs.

So I guess it is clear I have to take the engines out and do a full rebuild on both, so no need to wait for the Candoo. Can anybody recommend a good place where I can order parts, what oversize pistons I can get if I rehone the cylinders (or is it easier to buy new sleeves?), is it okay to shave of a bit off the heads to increase compression, or will that only make the engine fail soon?

I have attached a few photos of the parts that cause me problems

I found a dangling connector (2 core, black and green) behind the dashboard, does anybody know what that one is for?

On to the engine bay: Checked the MPEM visually, all fuses, terminals, overall condition, and it doesn't look to shabby. I found a bunch of connectors with caps and a busbar dangling roughly above the battery, what are they for? Once I have my Candoo, where does that get pugged into?

Connected a positive directly to the starter terminal with an in-line switch, and cranked the starboard engine until no fluid came out through the sparkplug holes - did many bursts about ten seconds, and then let the starter cool down again. Tried to test compression, got 110 at the Magneto side, and only 70 on the PTO side, but only because the starter didn't have enough strength to turn the engine over - the moment I took the tester off, it cranked over again pretty well, tester on, and it got stuck.

Tried the same with the board engine - starter spins, but doesn't engage, looks like the gear is seized and doesn't move forward.

Found massive corrosion holes at all welsch plugs.

So I guess it is clear I have to take the engines out and do a full rebuild on both, so no need to wait for the Candoo. Can anybody recommend a good place where I can order parts, what oversize pistons I can get if I rehone the cylinders (or is it easier to buy new sleeves?), is it okay to shave of a bit off the heads to increase compression, or will that only make the engine fail soon?

I have attached a few photos of the parts that cause me problems