Probably easier and more cost efficient to keep an eye out in your local market for someone parting out a boat

-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

96 Speedster - rookie troubleshooting workflow

- Thread starter lowspeedpursuit

- Start date

lowspeedpursuit

New Member

The thought had crossed my mind, but I live in kind of a weird spot. It's a peninsula that's suddenly become extremely rich over the past decade, so there's a lot less DIY community, everything for sale nearby carries a huge premium, and radius-based marketplace filters aren't smart enough not to try and send me directly across the bay on what's actually a 4hr one-way trip.

There's a partout listed in exactly such a location, actually, for an '04 Speedster. I'm having trouble figuring out if later access covers are "close enough" to fab into one of mine, but it doesn't seem worth the trip.

I also don't think I ever mentioned this part, but this was more-or-less a $300 boat. Repairs ($30 tach, 7x$50 carb rebuilds + needle seats + wear rings, $220 impeller) have been another $600. If the going rate for these things is $2-350 (ebay), that feels pretty wasteful. Same beef I have with the traction mat kits I see at $3-400.

Anyway, everyone knows boats aren't for poor people, more at 5.

There's a partout listed in exactly such a location, actually, for an '04 Speedster. I'm having trouble figuring out if later access covers are "close enough" to fab into one of mine, but it doesn't seem worth the trip.

I also don't think I ever mentioned this part, but this was more-or-less a $300 boat. Repairs ($30 tach, 7x$50 carb rebuilds + needle seats + wear rings, $220 impeller) have been another $600. If the going rate for these things is $2-350 (ebay), that feels pretty wasteful. Same beef I have with the traction mat kits I see at $3-400.

Anyway, everyone knows boats aren't for poor people, more at 5.

Last edited:

Ebay is always overpriced, if I’m selling something or buying I consider it to be worth roughly half of the average ebay price. I always shake my head when a post will come up with someone asking what is this worth. Last one I remember was a pretty minty 1997 GSX on FB group that was for sale for 1500.00 with a trailer. Lots of answers like I just sold mine for 500.00. and it’s worth 800.00 tops, meanwhile they just bought one for 600.00 with no trailer that needs everything, sitting outside its whole life, sink 600.00 in parts and countless hours into it, but no way is a garage kept machine with low hours worth 1500.09 lol.

lowspeedpursuit

New Member

Oh, absolutely, it goes both ways. Sellers want a million dollars for their stuff, but simultaneously buyers want to pay $3.50 instead of what stuff is actually worth.

I'm getting the impression boats have the same problem as motorcycles in being a lot less fabrication-friendly than cars and trucks. There's always some piece of plastic you've got to have, only the dealer ever sold it, and there's not really such a thing as the junkyard.

Without economies of scale, it goes like you're saying: buying all the parts a shitbox needs to be complete will run you more than it would just have cost to start with something nicer.

But, sometimes your budget is what it is, and if you want to play, you've just gotta do the best you can.

I'm getting the impression boats have the same problem as motorcycles in being a lot less fabrication-friendly than cars and trucks. There's always some piece of plastic you've got to have, only the dealer ever sold it, and there's not really such a thing as the junkyard.

Without economies of scale, it goes like you're saying: buying all the parts a shitbox needs to be complete will run you more than it would just have cost to start with something nicer.

But, sometimes your budget is what it is, and if you want to play, you've just gotta do the best you can.

lowspeedpursuit

New Member

I have a tentative plan for the access cover, but before that, starboard carbs are resisting achieving correct pop-off.

Manual spec is 40-56. Port, one carb with new parts came out at 48, and the other was high until I used one of the old levers to match.

Starboard MAG with all-new parts popped at 60+. Old levers were even higher. Bending the lever up to get 55 makes it contact the diaphragm and not hold pressure. But, the old needle pops at 56 with a flat lever. Short spring from the kit pops <40 (same as the port carbs), so that won't work.

Starboard PTO is off-the-charts high and won't pop at all with any combination of parts and the spring that's in there. The short spring and the old lever from the MAG carb (bent very slightly down) pops at 56. So that matches, and is barely in-spec, but involves using two different springs.

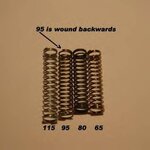

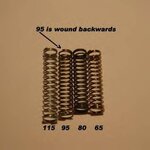

It looks like stock part #270500267 is supposed to be 80g, and based on

I'm looking at 95g in here right now. I have zero idea why all else being equal, PTO is so much higher than MAG.

Followup:

I can find posts saying mixing springs is not the move, but it was nice yesterday, and I wanted to see what would happen. What happened is the starboard engine started in my driveway, but not in the water, so we didn't take the boat out. Looks like the small spring was too weak and the PTO carb flooded. Now I know firsthand for sure.

80g springs have been in the mail, so we'll see if everything starts smoothly with those instead of the previous owners' 95g's. It looks like I've got some kind of aftermarket pod air filters, and conventional wisdom is those run lean, so I'm not sure why they would also have run leaner springs.

Ultimately, I guess I don't really get the point of checking pop-off. Nothing but the needle and spring system should factor in, so if you have all-new parts, and the stock spring size works the best regardless of pop-off reading... who cares what the reading is?

Manual spec is 40-56. Port, one carb with new parts came out at 48, and the other was high until I used one of the old levers to match.

Starboard MAG with all-new parts popped at 60+. Old levers were even higher. Bending the lever up to get 55 makes it contact the diaphragm and not hold pressure. But, the old needle pops at 56 with a flat lever. Short spring from the kit pops <40 (same as the port carbs), so that won't work.

Starboard PTO is off-the-charts high and won't pop at all with any combination of parts and the spring that's in there. The short spring and the old lever from the MAG carb (bent very slightly down) pops at 56. So that matches, and is barely in-spec, but involves using two different springs.

It looks like stock part #270500267 is supposed to be 80g, and based on

I'm looking at 95g in here right now. I have zero idea why all else being equal, PTO is so much higher than MAG.

Followup:

I can find posts saying mixing springs is not the move, but it was nice yesterday, and I wanted to see what would happen. What happened is the starboard engine started in my driveway, but not in the water, so we didn't take the boat out. Looks like the small spring was too weak and the PTO carb flooded. Now I know firsthand for sure.

80g springs have been in the mail, so we'll see if everything starts smoothly with those instead of the previous owners' 95g's. It looks like I've got some kind of aftermarket pod air filters, and conventional wisdom is those run lean, so I'm not sure why they would also have run leaner springs.

Ultimately, I guess I don't really get the point of checking pop-off. Nothing but the needle and spring system should factor in, so if you have all-new parts, and the stock spring size works the best regardless of pop-off reading... who cares what the reading is?

Last edited:

lowspeedpursuit

New Member

On what might be the last nice day of the season, 2nd test run was also mostly successful:

1. Replaced all 4 carb springs with black 80g Mikuni from OSD. In the process, I discovered the port carbs actually came to me with... one 95g and one 65g. I guess that's why the low-speed screws were set so weird. So, obviously that's not what prevented starboard from starting for the 2nd test run attempt. On a lark, I ran a wire through the pilot jets. I think a flake of black paint from the carbs clogged one of the pilot jets the first time I took them apart. Starboard now fires instantly.

2. Idles are synced, and throttles are 95%+ synced. Starboard cable is maxed out. I'm probably not going to fuck with it.

3. Driving and planing is way, way better. I had 1 or 2 runaway cavitations, which I think were more from the chop.

4. Redneck engine access cover is good to go:

It's the forward corner of an F150 bedliner cut to roughly fit the space, clamped to leftover 2" foam insulation with toggle bolts. It works way better than I expected, and the engine compartment didn't even come close to hitting the temp limit of the foam. Maybe still bears thinking about come summer water temps, I guess.

It's probably time to winterize, and off the top of my head, this leaves two problems I could still use advice on:

1. PO added speakers and a stereo in the glove box. Wiring is not the greatest. It's inconvenient that he didn't bypass the master battery cutoff with the yellow (memory keepalive power) wire. Is there any reason not to do this myself? Are these boats weak to parasitic drain?

2. I pulled a big pebble out of the speedometer pickup and sprayed it with electronics cleaner, but it still doesn't work. There were at least two times today--one during an unintended jump--that it spun up and registered a random number, so something is going on down there. Thoughts?

1. Replaced all 4 carb springs with black 80g Mikuni from OSD. In the process, I discovered the port carbs actually came to me with... one 95g and one 65g. I guess that's why the low-speed screws were set so weird. So, obviously that's not what prevented starboard from starting for the 2nd test run attempt. On a lark, I ran a wire through the pilot jets. I think a flake of black paint from the carbs clogged one of the pilot jets the first time I took them apart. Starboard now fires instantly.

2. Idles are synced, and throttles are 95%+ synced. Starboard cable is maxed out. I'm probably not going to fuck with it.

3. Driving and planing is way, way better. I had 1 or 2 runaway cavitations, which I think were more from the chop.

4. Redneck engine access cover is good to go:

It's the forward corner of an F150 bedliner cut to roughly fit the space, clamped to leftover 2" foam insulation with toggle bolts. It works way better than I expected, and the engine compartment didn't even come close to hitting the temp limit of the foam. Maybe still bears thinking about come summer water temps, I guess.

It's probably time to winterize, and off the top of my head, this leaves two problems I could still use advice on:

1. PO added speakers and a stereo in the glove box. Wiring is not the greatest. It's inconvenient that he didn't bypass the master battery cutoff with the yellow (memory keepalive power) wire. Is there any reason not to do this myself? Are these boats weak to parasitic drain?

2. I pulled a big pebble out of the speedometer pickup and sprayed it with electronics cleaner, but it still doesn't work. There were at least two times today--one during an unintended jump--that it spun up and registered a random number, so something is going on down there. Thoughts?

lowspeedpursuit

New Member

Are you fucking kidding me:

Trying to figure out what's up with sand in the water jackets or whatever. One bolt snapped off almost clean with the head. It's so corroded to the head, the head won't move one bit either.

EDIT: That was stupid. It's literally just stuck to the head and not the jug:

Pulled the air filter bracket and the exhaust manifold and spun the entire head around until it was out, which is good, I guess, since I can't weld or drill stainless.

Bad news is I'm entirely wasting my time and however much new head seals cost, since there's no sand in the jug, or the exhaust manifold. I already blew out all the lines, and I blew out the main exhaust pipe before I installed it in the first place.

I'm in here because the telltale was super weak, and a bit of sand comes out if you blow into it while it's running. What does that leave?

Trying to figure out what's up with sand in the water jackets or whatever. One bolt snapped off almost clean with the head. It's so corroded to the head, the head won't move one bit either.

EDIT: That was stupid. It's literally just stuck to the head and not the jug:

Pulled the air filter bracket and the exhaust manifold and spun the entire head around until it was out, which is good, I guess, since I can't weld or drill stainless.

Bad news is I'm entirely wasting my time and however much new head seals cost, since there's no sand in the jug, or the exhaust manifold. I already blew out all the lines, and I blew out the main exhaust pipe before I installed it in the first place.

I'm in here because the telltale was super weak, and a bit of sand comes out if you blow into it while it's running. What does that leave?

Last edited:

lowspeedpursuit

New Member

Incredibly nice dude sold me whatever I wanted off a '95 he was about to scrap, so I've got a bunch of stuff I never expected to be able to find:

1. Stock inner engine access cover w/ stock anchor light.

2. Stock airboxes & flame arrestors. Not sure if whichever PO installed pods rejetted the carbs, but I kind of doubt it. Also thinking stock airboxes might be even quieter.

3. Speedometer to see if it works any better or if I need to rebuild one.

4. Tool / dry storage containers for the glove box, spare gauges, throttles, dock lines, and some other stuff I'm probably forgetting.

The engines were gone, but there was a head laying there which unfortunately isn't directly compatible with the '96. Ditto for the computer (rectangular vs. round bulkhead connector). Not sure if combining the '95 head with my '96 head cover would cause a cooling snafu (the passages are different, not just the ports).

1. Stock inner engine access cover w/ stock anchor light.

2. Stock airboxes & flame arrestors. Not sure if whichever PO installed pods rejetted the carbs, but I kind of doubt it. Also thinking stock airboxes might be even quieter.

3. Speedometer to see if it works any better or if I need to rebuild one.

4. Tool / dry storage containers for the glove box, spare gauges, throttles, dock lines, and some other stuff I'm probably forgetting.

The engines were gone, but there was a head laying there which unfortunately isn't directly compatible with the '96. Ditto for the computer (rectangular vs. round bulkhead connector). Not sure if combining the '95 head with my '96 head cover would cause a cooling snafu (the passages are different, not just the ports).

lowspeedpursuit

New Member

Good call, the more I looked at it, the head cover seal is 100% different.

Got the starboard engine back together and started both with the stock airboxes. Starboard actually starts easier at this point. Idled higher, but seemed to run fine. Guess I'll bring the pod filters along for the first test-run next Spring just in case.

Turned the fuel selectors off, ran antifreeze into both heads, installed valves on the lines from the oil tank, and pulled the scupper ball off.

Still gotta test the other speedo, trim the back corners slightly to make the '95 access cover fit, pull the battery, put the cover on, and park it.

Got the starboard engine back together and started both with the stock airboxes. Starboard actually starts easier at this point. Idled higher, but seemed to run fine. Guess I'll bring the pod filters along for the first test-run next Spring just in case.

Turned the fuel selectors off, ran antifreeze into both heads, installed valves on the lines from the oil tank, and pulled the scupper ball off.

Still gotta test the other speedo, trim the back corners slightly to make the '95 access cover fit, pull the battery, put the cover on, and park it.

Similar threads

- Replies

- 13

- Views

- 632

- Replies

- 8

- Views

- 604

- Replies

- 0

- Views

- 419

- Replies

- 5

- Views

- 693

- Replies

- 1

- Views

- 335