vert

Member

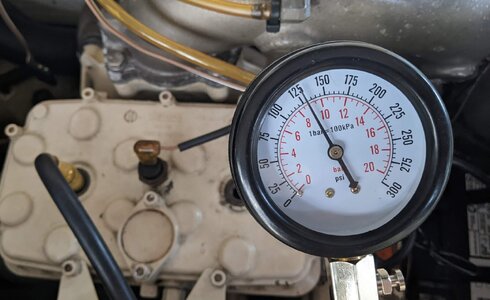

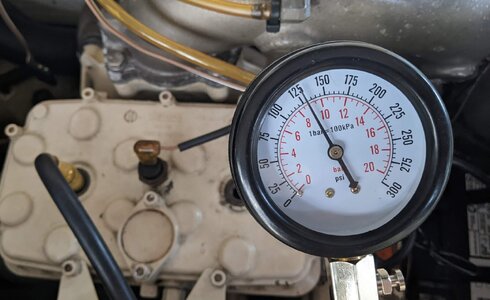

Second compression test results with a different tester, cheap one from Amazon. Both cylinders around 130 psi. It was bouncing between 125 and 130 at WOT, cold engine, both plugs out. One cylinder happened to stop the needle at just over 125 the other right at 130. The loaner tester from Autozone was not bouncing like this and ended up at around 135 on both.