boatrboy

Active Member

Although I have a lot of experience working on boats (pretty decent mechanic) I'm new to the PWC world so take it easy on me  .

.

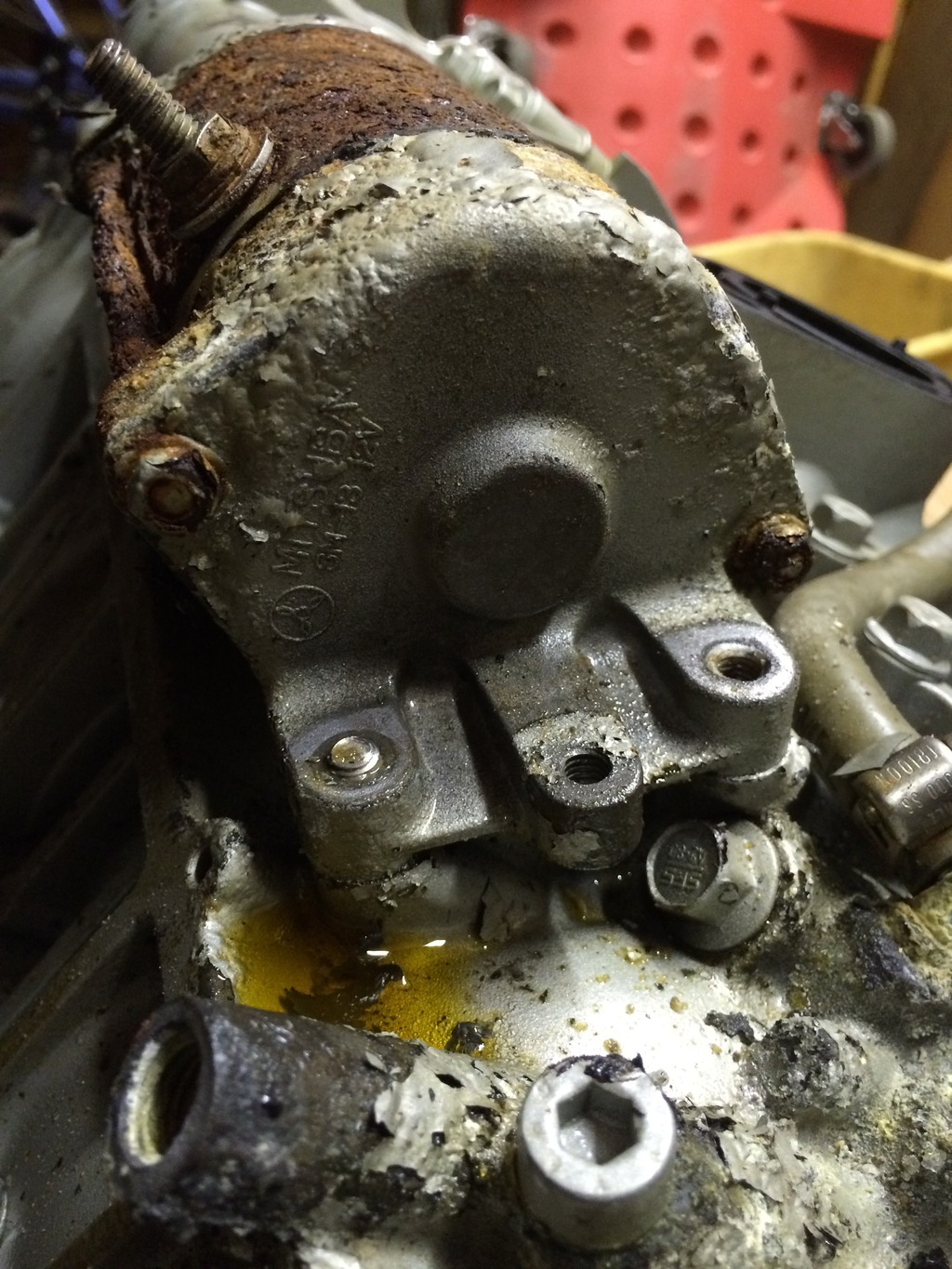

Short history - I purchased this ski from a friend not running after a horrific knock. So far I have removed the head and found the rear (assuming when I see PTO it means rear) piston badly damaged and actually missing the wrist pin bearing. I want the engine out on the bench so I can evaluate the lower end. I'm not sure what damage it did to the rod and will need to decide to go with a rebuilt motor or just top end. I have the exhaust, rave's and carbs's off with everything labeled and photographed.

1) At this point all I need to do is disconnect the drive shaft and unbolt the lower block and pull it out. I unbolted the six (or so) bolts on the PTO adapter thinking it would pop off the flywheel and slide back on the splines and give me enough room to pull the motor up. I gave it some love taps but to no avail. Do I really need to pull the pump off and leave this assembled to the motor for now????

Should I unbolt the rear motor mount from the hull, or take out the bolts attaching the block to the motor mount?

I read many posts so far and realize there is an alignment to be concerned about, but right now I just want the motor out.

2) Many posts suggest that the root cause of a blown cylinder on these motors is due to lack of oil (bad oil pump), clogged oil lines and grey Tempo gas lines breaking down causing lean carb mixture. Most of these lines are metric sizes. They are close to standard sizes sold in auto parts stores - is that what most of you use?

Any advice would be greatly appreciated.

Mark

p.s. this is NOT a DI version

Short history - I purchased this ski from a friend not running after a horrific knock. So far I have removed the head and found the rear (assuming when I see PTO it means rear) piston badly damaged and actually missing the wrist pin bearing. I want the engine out on the bench so I can evaluate the lower end. I'm not sure what damage it did to the rod and will need to decide to go with a rebuilt motor or just top end. I have the exhaust, rave's and carbs's off with everything labeled and photographed.

1) At this point all I need to do is disconnect the drive shaft and unbolt the lower block and pull it out. I unbolted the six (or so) bolts on the PTO adapter thinking it would pop off the flywheel and slide back on the splines and give me enough room to pull the motor up. I gave it some love taps but to no avail. Do I really need to pull the pump off and leave this assembled to the motor for now????

Should I unbolt the rear motor mount from the hull, or take out the bolts attaching the block to the motor mount?

I read many posts so far and realize there is an alignment to be concerned about, but right now I just want the motor out.

2) Many posts suggest that the root cause of a blown cylinder on these motors is due to lack of oil (bad oil pump), clogged oil lines and grey Tempo gas lines breaking down causing lean carb mixture. Most of these lines are metric sizes. They are close to standard sizes sold in auto parts stores - is that what most of you use?

Any advice would be greatly appreciated.

Mark

p.s. this is NOT a DI version