JC-SUPERJET

Active Member

The Check Valve Discs are cut from Plastic Sheets that come in ROLLS.

What that means is that the Check Discs will not be perfectly flat due to curl deformation.

This implies that there is only one side of the Disc that will lay flat and seal tight, and that is the side with the Sharpie Mark on them.

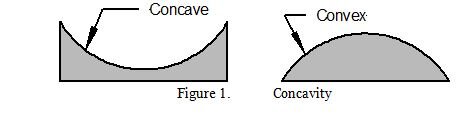

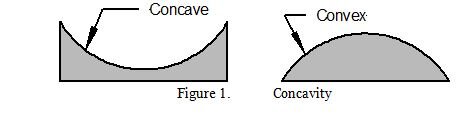

Another way to determine correct Disc Side to face down, is to mate the concave side to the Flange.

This will ensure a good seal because, the built-in "camber" will seal tight since the Disc will be under tension against the Flange when forced to lay flat by the Rubber Pin.

What that means is that the Check Discs will not be perfectly flat due to curl deformation.

This implies that there is only one side of the Disc that will lay flat and seal tight, and that is the side with the Sharpie Mark on them.

Another way to determine correct Disc Side to face down, is to mate the concave side to the Flange.

This will ensure a good seal because, the built-in "camber" will seal tight since the Disc will be under tension against the Flange when forced to lay flat by the Rubber Pin.

Last edited: