This is coming out of left field so bear with me.

Does anyone know the oil temp or surface temp of the RV gear cavity area? A thermal map is present, just unknown for my Sea Doo.

I worked with various industrial screw compressors where temps mattered from start to finish & that is an understatement. ( circulated oil with aftercooler, that is)

Syn oil performs best in & around 180/220ish deg & depending on the environment/ambient temps, the "formula or setpoints " can be tweaked.

I have non reversible hi temp strips but I can't answer my own question until this summer & if I want to pull a rabbit out of my hat, the time would be before, not after.

So that being said......

A couple of sources from the

aviation side of the tracks puts their

engine temps anywhere in the range of 160/185 degrees @ the bottom cases. They didn't use temp strips, instead opted for IR gun.

On uncirculated oil temp @ RV gear cavity? No data to pin down specifics so just "spit balling" here but with open loop cooling, ballpark of 135/140

ish deg range(?)Honestly, wont know until I put the temp strips on my own craft this summer.

Anyway,

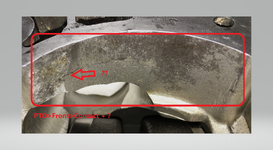

moving on towards the closed loop circuit on the RV gear cavity.

This area is going to get as much anal retentiveness that I can afford. I

do not want to put up with a headache that seems to plague these engines/operators.

I want this craft to be passed down @ least a generation before it's melted down & made into razor blades.

Imo, it's a weak link just because I have no experience with oil injected, rotary valve two strokes. I am out of my "comfort zone" with this concept.

That plus I'm getting to old for this shift. I don't do headaches as good as I use to.

The rest, CW/two stroke rebuild procedure?

Old hat.

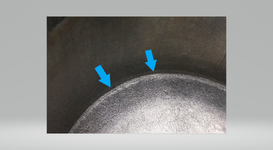

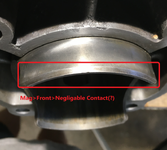

The crank/seals has only 40 hrs & it shows. Both seals /bearings are in outstanding shape. So, first & foremost, the inner seals go in absolutely

dry, period.. Seal valley in cases ,will be devoid of any containments/moisture, no mystery there. Already "nested" (with previous witness line @ 90 deg), the seals/crank in case & there is no hint whatsoever that spinning would occur. Fitment is spot on & up to the task it was designed to do under torque.ID of seal

seems uncompromised(?).

Incorporating Hydro Gear tank assembly, 350ml, just shy of 12 oz that's translucent so as to witness level & to be placed in the best height relationship(?) with the actual level in RV gear cavity. I do know the static pressure imparted on cavity will be reduced. This tank is going to undergo some slight modifications so as to easily disconnect (w/o the mess),

gently (cannot emphasize "gently" enough), purge, flush/circulate gear cavity. I

do expect to see bronze "dustings" (

not slivers) in the oil removed. Hardened steel moving on bronze, of course. Expected decrease in dustings as gears mate & "settle in". If sudden increase in dustings, alarms go off. Simple logic.

Fast forwarding...

Break in? Somewhat different than what I'm used to but I do realize that this is a different animal & by the way, BIG Shout out to this forum & SD enthusiast who pointed me in the right direction.

Allow me to share what I know of "break ins" on two strokes I've learned over the years. (bring a few sets of new plugs) & use NON-ETHANOL.

*Initial carb adj,>stay rich

but not to the point of underperforming during the varying of RPMs required in proper break in.

Next level of the varying higher RPMs,>again stay rich but read the plugs, the

full measure read. cut up the plug & read the ceramic. Make determination,>adj but still stay on the rich side of "correct", Do this during cool down in the heat cycle.

Continue this throughout the break in period & for Pete's sake, have the patience & stick to the regimented break in procedure.

After "successful" break in, again bring a few more sets of new plugs & then perform WOT throttle chops & again cut plug, read ceramic>adj, rinse & repeat until that "perfect burn" & then just the smallest tweak to the rich side of correct.

* If there's

only ETHANOL @ your destination, bring a couple of gallons of NON-ETHANOL (don't forget to premix if applicable) but go ahead & use the available ethanol there just be sure to run tank low/out before the extended, lengthy shutdown, few days>weeks. Pour in, run a minute or two> shutdown.

On the travel back, just remember...

OBEY ALL TRAFFIC LAWS!