erikryan88

New Member

We just bought this boat about 2 weeks ago. After extreme cleaning, working out some issues, replacing plugs/oil, getting it running, getting it licensed we finally dropped it into the water today to see what it would do. And boy was that disappointing.

I had no power to go in reverse. Going forward was fine up to about 10-15mph, after that it revved really high and wouldnt go anywhere, like a slipping clutch. The starboard engine was quicker to do this than the port side but both have the issue.

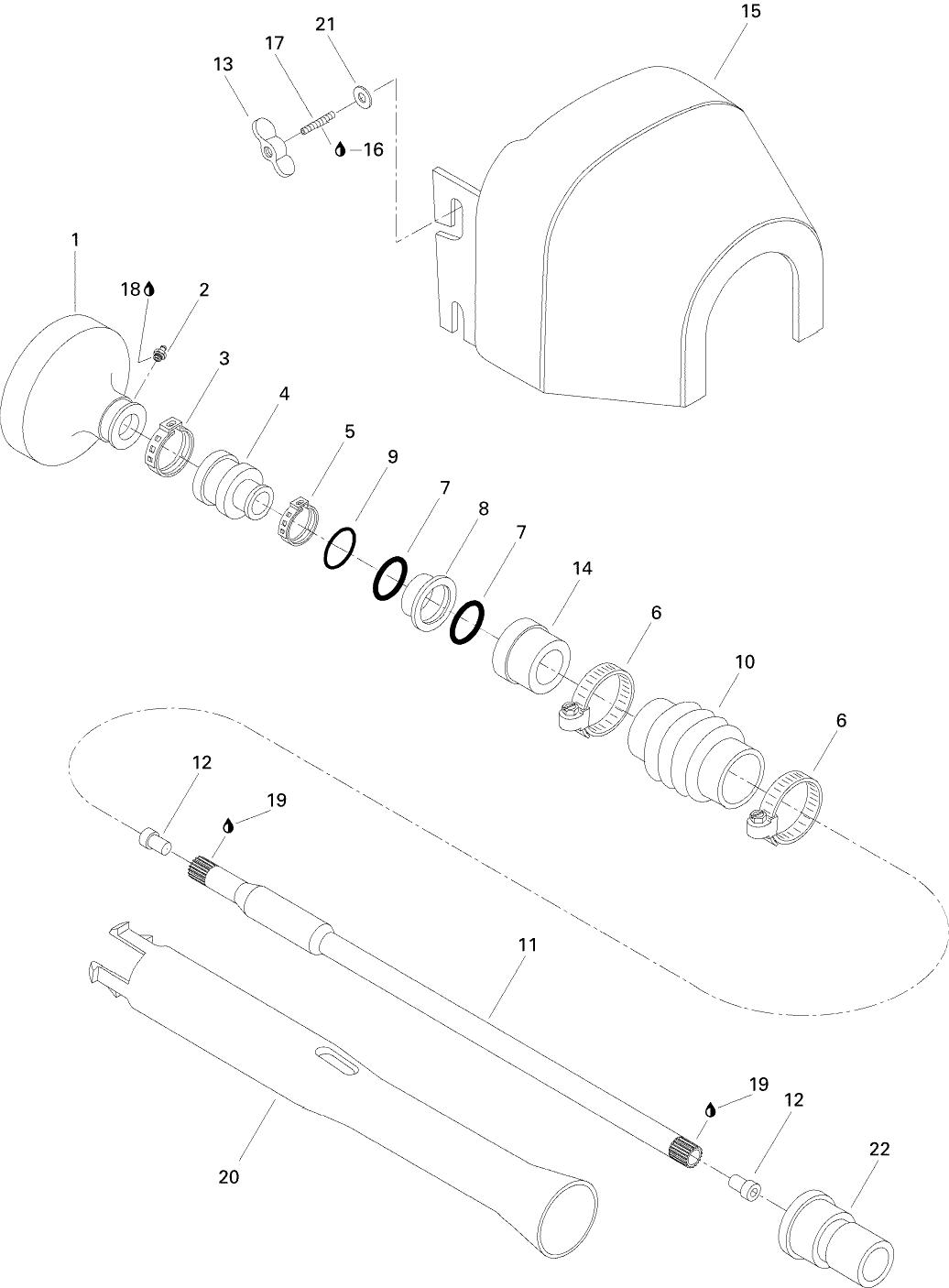

In the middle of the lake, annoyed, I googled and found this forum and possible causes. I limped it back to the trailer, got it home and pulled both jet pumps off. Both wear rings have a good amount of wear, looking down the side, i can see a decent sized gap. On one, the prop rubs in one spot so it looks a bit more rough.

Would you guys think its safe to say these rings are my issue? Can anyone point me in the direction of a sticky that has thorough directions in replacing these? Seals/orings that need ordered in addition to the rings? I may try and order a new prop for the one thats rubbing as it looks rather rough. Finding parts for these boats hasnt been easy thus far.

Im completely new to boat ownership and its not off to a good start.

Thanks in advance

I had no power to go in reverse. Going forward was fine up to about 10-15mph, after that it revved really high and wouldnt go anywhere, like a slipping clutch. The starboard engine was quicker to do this than the port side but both have the issue.

In the middle of the lake, annoyed, I googled and found this forum and possible causes. I limped it back to the trailer, got it home and pulled both jet pumps off. Both wear rings have a good amount of wear, looking down the side, i can see a decent sized gap. On one, the prop rubs in one spot so it looks a bit more rough.

Would you guys think its safe to say these rings are my issue? Can anyone point me in the direction of a sticky that has thorough directions in replacing these? Seals/orings that need ordered in addition to the rings? I may try and order a new prop for the one thats rubbing as it looks rather rough. Finding parts for these boats hasnt been easy thus far.

Im completely new to boat ownership and its not off to a good start.

Thanks in advance