-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1996 seadoo xp cylinder bore

- Thread starter Jakem1

- Start date

- Status

- Not open for further replies.

Group K, best of the best.

Group K – PURELY TECHNICAL Online

Group K – PURELY TECHNICAL Online

You should not have to ship them anywhere. 2-stroke bore is a simple task.I have a 96 xp and I’ve called nearly every machine shop around any they don’t bore my kind of ski. Does anyone know somewhere that I can go to?

If I have to I will ship them.

(AUSTIN AREA)

You would think, but most machine shops today do not chamfer the ports as they should. There is not a single local machine shop that I would trust with 2-strokes.You should not have to ship them anywhere. 2-stroke bore is a simple task.

Perhaps we are from different eras and areas. In South Louisiana lots and lots of 2 stroke engines and people with experience. Even young people around here were brought up on two-strokes and still use them daily. My friend VJ has been boring cylinders since the 1960's. I have friends on the bayou that only bore one cylinder and leave the others alone. Engine has been running 10 years. They ain't spendin all that money. LOL I love it down here.You would think, but most machine shops today do not chamfer the ports as they should. There is not a single local machine shop that I would trust with 2-strokes.

Yes, remember we here in California have tried to ban all 2-strokes for many years sadly.Perhaps we are from different eras and areas. In South Louisiana lots and lots of 2 stroke engines and people with experience. Even young people around here were brought up on two-strokes and still use them daily. My friend VJ has been boring cylinders since the 1960's. I have friends on the bayou that only bore one cylinder and leave the others alone. Engine has been running 10 years. They ain't spendin all that money. LOL I love it down here.

Talbees XP

Member

Having same problem here In mid West Florida, nobody machines 2 strokes go figureI have a 96 xp and I’ve called nearly every machine shop around any they don’t bore my kind of ski. Does anyone know somewhere that I can go to?

If I have to I will ship them.

(AUSTIN AREA)

Talbees XP

Member

I was quoted 75 a cylinder and 25 for chamferYou gotta find an old guy with a cylinder boring machine and NOT a machine shop. How much ya'll paying?? I got a buddy been boring cylinders since the 1960's.

I guess I don't know how to chamfer.... LOL these people can sure come up with some stuff. $25...Good grief. VJ and I talk about boring cyinders but it isn't something either of us want to do, especially the shipping and such.I was quoted 75 a cylinder and 25 for chamfer

Got a guy on the internet building engines people are raving about. He charges $2400 for a 787 and when I questioned the price his cronies said, "quality work costs money." That's good bullshit as well. It's a jungle out there. I'm a firm believer that if you want to control cost, time frame and quality.... best do it yourself. Good Luck !!

I agree with you, however the typical DIY mechanic does not have the skill set nor the equipment required to do cylinder boring unfortunatelyI guess I don't know how to chamfer.... LOL these people can sure come up with some stuff. $25...Good grief. VJ and I talk about boring cyinders but it isn't something either of us want to do, especially the shipping and such.

Got a guy on the internet building engines people are raving about. He charges $2400 for a 787 and when I questioned the price his cronies said, "quality work costs money." That's good bullshit as well. It's a jungle out there. I'm a firm believer that if you want to control cost, time frame and quality.... best do it yourself. Good Luck !!

Sounds like there are a lot of business opportunities regarding boring cylinders. You won't get rich but you'll make a few $$ and a lot of people happy. I could take a picture of my $5 Harbor Freight CHAMFER tool.  All you are doing is eliiminating the sharp edge on the ports so they don't hook a ring. Doesn't take much.

All you are doing is eliiminating the sharp edge on the ports so they don't hook a ring. Doesn't take much.

for sure I would like to see a picture of the tool, I would attempt to chamfer the ports after consulting someone who’s done it. From what I’ve read you can do it with a series of round files or with a dremel. Myself I would feel more comfortable going slow with the filesSounds like there are a lot of business opportunities regarding boring cylinders. You won't get rich but you'll make a few $$ and a lot of people happy. I could take a picture of my $5 Harbor Freight CHAMFER tool.All you are doing is eliiminating the sharp edge on the ports so they don't hook a ring. Doesn't take much.

Nothing to it. I use a small course triangle file from harbor freight. In the corners or where there is a radius I use a round course file. Just a slight taper/bevel is all you need. You remove the sharp edge. If you use a dremel or die grinder it's really easy to mark the bore by accident... I've done it which is why I use a small file. Takes about 15-20 minutes to do both cylinders. Just a little common sense.. Easy Peasy.for sure I would like to see a picture of the tool, I would attempt to chamfer the ports after consulting someone who’s done it. From what I’ve read you can do it with a series of round files or with a dremel. Myself I would feel more comfortable going slow with the files

Talbees XP

Member

my thoughts exactly, i may just grab a hone and check some youtube tutorials, there is a guy on there who in the past has worked on older pwc Sebastian bluecrew is his nameI agree with you, however the typical DIY mechanic does not have the skill set nor the equipment required to do cylinder boring unfortunately

Talbees XP

Member

I was thinking the same thing,Sounds like there are a lot of business opportunities regarding boring cylinders. You won't get rich but you'll make a few $$ and a lot of people happy. I could take a picture of my $5 Harbor Freight CHAMFER tool.All you are doing is eliiminating the sharp edge on the ports so they don't hook a ring. Doesn't take much.

Talbees XP

Member

so would I, didnt even know what the chamfer was had to look into it to see if he was pulling my chainfor sure I would like to see a picture of the tool, I would attempt to chamfer the ports after consulting someone who’s done it. From what I’ve read you can do it with a series of round files or with a dremel. Myself I would feel more comfortable going slow with the files

Talbees XP

Member

cool, i can get with thatNothing to it. I use a small course triangle file from harbor freight. In the corners or where there is a radius I use a round course file. Just a slight taper/bevel is all you need. You remove the sharp edge. If you use a dremel or die grinder it's really easy to mark the bore by accident... I've done it which is why I use a small file. Takes about 15-20 minutes to do both cylinders. Just a little common sense.. Easy Peasy.

Lol, no I have yet to see anyone on here misdirect someone on purpose.

Talbees XP

Member

I may also grab one cylinder from a seller on ebay, I have picked up a couple parts from a fresh water parts pwc and they are good parts, my pto cylinder piston is trash from previous owner, picked it up without a trailer for 150.00

I think lots of times vendors want you to believe only they can do a quality job. I fixed this guys ski that had about vibrated itself to pieces. It was a piece of crap and I told him to ride it till it blows. That's been 3 years ago. LOL He thinks I'm a good mechanic. Ha ha. He's wrong. I didn't do anything other than replace everything that fell off or broke and realign the engine. Gotta love it !!my thoughts exactly, i may just grab a hone and check some youtube tutorials, there is a guy on there who in the past has worked on older pwc Sebastian bluecrew is his name

Modesty is a virtue but those that are on the forum know that you can fix just about anything on these machinesI think lots of times vendors want you to believe only they can do a quality job. I fixed this guys ski that had about vibrated itself to pieces. It was a piece of crap and I told him to ride it till it blows. That's been 3 years ago. LOL He thinks I'm a good mechanic. Ha ha. He's wrong. I didn't do anything other than replace everything that fell off or broke and realign the engine. Gotta love it !!

There is much more to it than grabbing a few files and having at it.

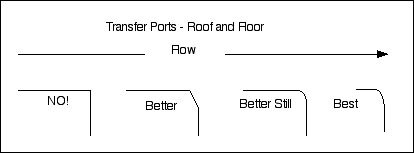

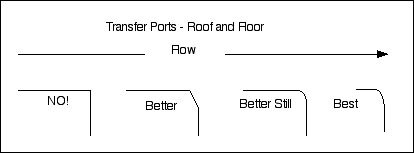

First, is the step and the angle as the piston ring is actually moving in and out of the groove as it travels past the port. So you need to control the speed and pressure on the ring. A poor chamfer will work but a good chamfer will increase the ring life.

The second is the shape. The better the shape the better the flow and the spec design of the port. The chamfer is the first path of the flow and port opening and closing. So an expert will actually shape the chamfer for maximum performance. This is why I have one of the best builders in the industry do my cylinders.

First, is the step and the angle as the piston ring is actually moving in and out of the groove as it travels past the port. So you need to control the speed and pressure on the ring. A poor chamfer will work but a good chamfer will increase the ring life.

The second is the shape. The better the shape the better the flow and the spec design of the port. The chamfer is the first path of the flow and port opening and closing. So an expert will actually shape the chamfer for maximum performance. This is why I have one of the best builders in the industry do my cylinders.

- Status

- Not open for further replies.

Similar threads

- Replies

- 36

- Views

- 1,217

- Replies

- 4

- Views

- 301