Re: 657 vs 657x

First off all 1994 XP's come stock with 657X motors. The ID tag is on top of the magneto housing.

The differences,

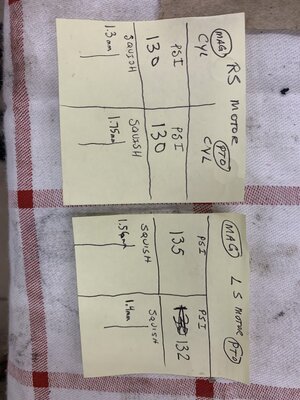

The cases are different, 657X cases are thicker walled and have a 1mm higher deck height.

The crankshafts are easily ID'ed by the holes drilled through the counterbalancer webs on the 657 crank, and the Labrinyth seal on the back of the 657X crank, plus no holes in the counterbalance webs on the 657X crank.

The clyinders are the same on both motors, but the heads differ. The 657 head has a step cut squish band and the 657x head does not have a step cut squish band.

When you remove a 657 head, you will see the piston rises all the way to the top of the clyinder sleeve and the 657X piston will only rise up to within 1mm of the top of the sleeve when you set it at TDC.

In 1994 XP's, they used the SBN 38mm I series carbs. In the 1994 SPX and GTX ( dual carb models that are not XP's ) they used the SBN 38mm carbs ( you can easily tell the difference by looking at the way the carb bolts onto the manifold. The SBN's use nuts to hold them onto the intake manifold and the 657X I series carbs use allen bolts through the whole carb body to attach them to the manifold. There are three bolts holding the airbox mount on a 657 carbs and two bolts on the 657X carbs.

The RV covers and intake manifolds differ, as the 657X has larger oval ports in the RV cover and engine cases, and the intake manifold has a different bolt pattern on the top and where it bolts to the RV cover.

The 657X pto flywheel is shaped differently, and it has a dual coil stator and a different Magneto flywheel.

There are different ignition modules in both models, and different coils.

Is that what you wanted to know?

Last edited by

Watercraft Magic; 08-08-2007, 12:13 PM.

If there is a 1mm difference in the two cylinders heights, you are mixed up about something. The pistons in the 1993 motor came to the top of the bores, thus the recessed squish bands in '93 heads. the '94 motor, the X, had pistons lowered by 1mm in the bores, and no cut into the chamber squish bands to even out the compression ratio of the two 657 motors.

Also, do not tell people that you can use a 657X head to raise compression on any non X 657. It will only last minutes in an engine with piston crowns at the very top of the bores before it melts the aluminum on the piston crown and if run lng enough, either blow a hole in the center of the piston, or detonate the rings and edges of the piston crowns so badly that they break off. It will for sure overheat and seize. You cannot run a two stroke motor without minimum squish clearances for the quality and octane fuel that is being run through it.

And like Dan pointed out, you got your X crank mixed up with your 657 crank if both came from the correct model years of XP's, 1993 and 1994.

In an effort to make a lighter full circle crank, Rotax needed to put large holes in the counterbalancer full circle weights, and make them thin and light as possible while still maintaing some reasonable amount of harmonics in the engine so it would not crack the engine cases, rotary valve surfaces above the top case, and shatter the intake manifolds. In doing so, the 1993 657 crankshafts were weaked to the point when they got hot from hard running, and were put under the shocking stresses of an impellor losing and regaining bite as the hull was sometimes in the air and other times in the water, it would twist the crankshafts in a heartbeat. I never checked index on a used 1993 crank without finding it way out of spec, sometimes twisted a quarter of the way around. Because the counterblancer flywheels on the '93 crankshafts were made the way they made them, the pins in them would loosen in their holes as the crankshaft flywheels expanded with heat. One good yank on the impeller would twist a crankshaft out of index. Imagine the twist on a driveline and crankshaft when an XP came down from jumping a wave with the rider still pinned on the throttle to rev limiter hieghts. That was the cheezeist crank that Rotax ever put into a Sea Doo hull. Good idea, bad results.

If you closely inspect the two PTO's, they are quite different too. One is heavier than the other. And that effects the absorbtion of engine harmonics, a terrible problem for a two clyinder motor. Seems to me, the 1994 PTO was shaped much differently than the two in your pictures. It was shaped more like the 720 pto. with the majority of the weight further away from the centerline of the crankshaft which is a big factor in torque production.

The cases are different for other reasons, mainly to make X cases stronger. The thickness of the aluminum in most all areas is thicker. When we were cutting cases for 4mm stroker cranks to fit into them, we had to add alot of aluminum to the lower part of the cases right at the bottom of the cases, by welding layers of aluminum onto the bottom of the cases, before we flycut the cases to clear the longer stroked crankshafts in 1993 cases. But no extra aluminum is needed in 1994 cases, until we tried as much as 8mm strokers...........

The area right where the rotary valve surface is above the upper case half, if you look at the two closely, you will notice reinforcment webs supporting that thin aluminum rotary surface above the cases where 1993 cases allways crack but not on 1994 X cases.

The two intake manifolds have totally different stud alignment as they are inline with short studs on a 1993 inatake manifold, and non existant studs, and replaced with threaded holes that are both angled on the manifold and not inline with each other at all. I series carbs use long hex bolts to hold the carbs on. '93's use nuts on studs that are frustrating and difficult to remove or even access with conventional SBN carb flanges on inline shaft to shaft carb sets.

They probably eliminated the case drain plugs because nobody ever really used them. They are extremely difficut to access when that motor is in a Sea Doo hull. Kinda like the drain plug in a 787 case, it is accessable if you know it is there, and not in an XP model, but a screw-in cap above the counterbalance drive gear is so much easier to remove and then suck the water out.

The two motors share only a few parts that were not changed. the head cover, the rods are the same specs I believe. I am not even sure if the bearings on the crank were exactly the same spec, but they are interchangeable on either crank. I think the 1994 bedplate may even be stronger, not sure though. I believe they used the same oil pumps on both motors. And maybe the woodruff keys in the crank snouts. Pistons fit either motor.

I am sure I forgot more than I remember.