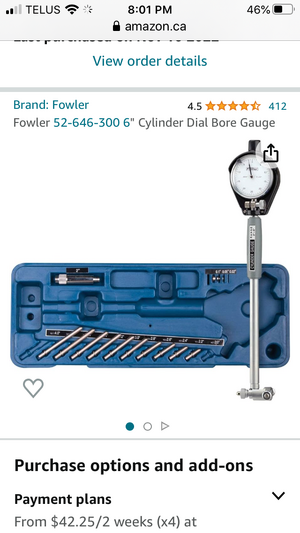

Hi all, I’m just starting to do a little research on measuring the runout on crankshafts. Thought I would start by asking everyone here a few questions. I have a Fowler dual bore gauge, and I was wondering if there would be a stand with a base that I could buy that would turn this dual bore gauge into a dial indicator that I could use? I’ve done a little looking online but all I’ve been seeing so far are dial Indicators with the base. I’m completely new with measuring the runout so any advice with anything to do with this would be great. I know with the ski doo’s the manual states that I can measure runout with everything still together with just the primary clutch removed. With the seadoo’s probably be mainly 657x 717 and 787 cranks could I test the runout with the crank sitting in one side of the crankcase or do I need a set of V blocks? I’ve watched a couple video’s of people rebuilding cranks, 1 was a 717 where he was trueing the crank by hitting what looked like the counter balance but I’m not sure for sure what he was hammering on, anyways just like to start by getting the proper tools and knowledge for measuring the runout.

Hi all, I’m just starting to do a little research on measuring the runout on crankshafts. Thought I would start by asking everyone here a few questions. I have a Fowler dual bore gauge, and I was wondering if there would be a stand with a base that I could buy that would turn this dual bore gauge into a dial indicator that I could use? I’ve done a little looking online but all I’ve been seeing so far are dial Indicators with the base. I’m completely new with measuring the runout so any advice with anything to do with this would be great. I know with the ski doo’s the manual states that I can measure runout with everything still together with just the primary clutch removed. With the seadoo’s probably be mainly 657x 717 and 787 cranks could I test the runout with the crank sitting in one side of the crankcase or do I need a set of V blocks? I’ve watched a couple video’s of people rebuilding cranks, 1 was a 717 where he was trueing the crank by hitting what looked like the counter balance but I’m not sure for sure what he was hammering on, anyways just like to start by getting the proper tools and knowledge for measuring the runout.-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

Tool to measure runout on crankshaft

- Thread starter burtshaver2021

- Start date