Toolanddiemaker

Active Member

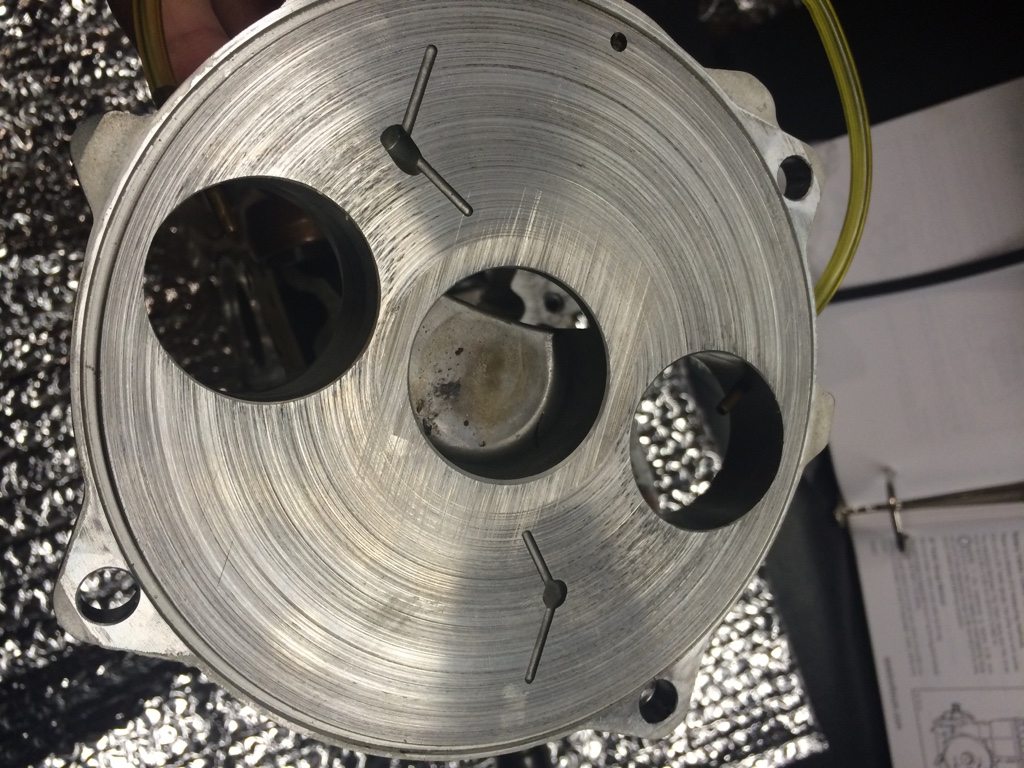

I just put the lower end together today on my 657 build and decided to check the clearance on the rotary cover I checked it with the rosin core solder method and with 45 degree feller gauges I got .015 with the solder and a micrometer the book says .012 plus or minus.002 so I'm basically a .001 out of tolerance the feller gauge showed .014 going in and the .015 was tight so there both close. I tested with a new valve plate and no o ring torqued to 15ft pounds. Is .001 out worth the $100.00 for a rework at sbt or will I be ok? On my speedster motors I sent them out because they were .008 out and started hard prior to rebuild but this motor fired right up prior to rebuild. Any suggestions? Thanks!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk