-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

new 951 di engine needs to be primed/bleed but HOW?

- Thread starter ricardo1

- Start date

- Status

- Not open for further replies.

68ragtop

Well-Known Member

I am under the impression that the maint warnings & limp mode will self restore once the triggering source/problem is corrected. I know that was the case with mine. I am also pretty sure all triggered history codes are stored long term in the MPEM even long after the issue is resolved.

Sportster-2001-951C-Stock

Well-Known Member

Yes, once the fault issue is resolved the MPEM will no longer indicate there was a problem but it will remember for xxx number of engine starts so you can still pull the code much later after the problem was corrected. The code history will still be there until cleared by BUDS/VCK basically, so best thing to do with BUDS/VCK is to clear all codes and then look for code that won't clear, this code will relate to the problem.

Good luck with it, let us know what BUDS says!

Good luck with it, let us know what BUDS says!

Sportster-2001-951C-Stock

Well-Known Member

This reading must be in the unit of centigrade, I guess, if so then this must be the issue b/c water boils at that temperature and surely should make an fault code appear.

Now you have an exact direction to follow, thanks to BUDS system.

Now you have an exact direction to follow, thanks to BUDS system.

Sportster-2001-951C-Stock

Well-Known Member

I thought you tested the resistance of all the sensors at the AMP connectors already? did you skip the water temp sensor?

I think he tested at the sensor, so most likely it's a broken wire or damaged connector pin.

Getting VERY close, do you have your swimming shorts and life vest on?

68ragtop

Well-Known Member

Getting VERY close, do you have your swimming shorts and life vest on?

I would like that to happen up here soon. Haven't even had my RX in the water yet since I have owned it.

50 degrees today. But, at least the sun is shining.

ricardo1

Active Member

Yes that's what the owner of the dealer said, either a bad wire or the contact on the ecu.I think he tested at the sensor, so most likely it's a broken wire or damaged connector pin.

Getting VERY close, do you have your swimming shorts and life vest on?

As soon as he said what sensor it was I got my diagram up and wrote down that its unit 4 9 and 11.So Unplug #4 at the MPEM again & check pins #9 & #11 supposed to be 2280 - 2740 (or 2.28k - 2.74k)

I would like that to happen up here soon. Haven't even had my RX in the water yet since I have owned it.

50 degrees today. But, at least the sun is shining.

Tell me about it man, last time I was in the water was on my 97 xp months ago it was a nice 70 degrees out today.

Sportster-2001-951C-Stock

Well-Known Member

You're STILL at work?!?!? :O

Sportster-2001-951C-Stock

Well-Known Member

I would like that to happen up here soon. Haven't even had my RX in the water yet since I have owned it.

50 degrees today. But, at least the sun is shining.

It's still broken until you splash it for testing! I think Ricardo's got you beat!

ricardo1

Active Member

You're STILL at work?!?!? :O

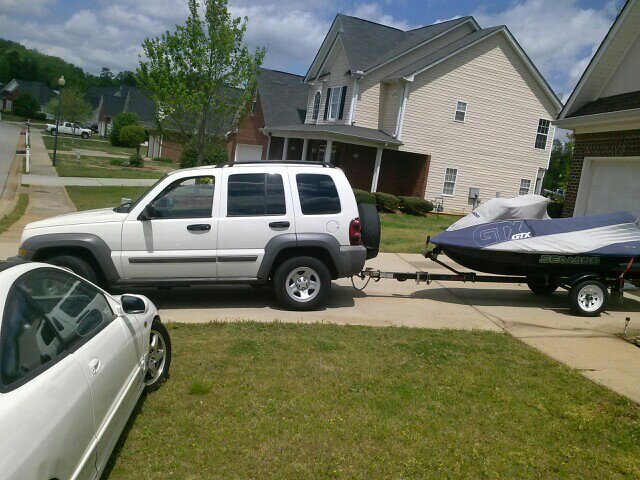

That was when I got back from the dealer and I had to change and go in but I was running late and since I work 2 miles from the store and just came to work with the ski on it. Just took this picture at work.

Last edited by a moderator:

Sportster-2001-951C-Stock

Well-Known Member

I found out what it was, you guys won't believe me. Sooo I had the knock sensor and the engine temperature sensor connected backwards I started the ski and bam no maint nor red light!!!!! Thanks a lot guys.:cheers:

Excellent, and yes I can believe that!

ricardo1

Active Member

Excellent, and yes I can believe that!

I got the water hose on the ski and rev the ski and it read 6300 rpm which is a little low if my memory serves me correct when I read the manual. I need to put loads of black rtv seal on the cooper ring in the exhaust pipes so It doesn't leak correct? asking because of the little exhaust leak I have between the two pipes.

I also ordered a new wear ring and the elbow for the oil tank since its leaking a little. Hopefully tomorrow after paintball practice I take the ski out for couple of hrs and have some fun.

Sportster-2001-951C-Stock

Well-Known Member

I think you have to put the ski in the water to test max RPM, should be around 7000 to 7200 in water WOT top speed. The reason is I expect, possibly the MPEM programing may not allow out of water rev to 7000? I don't have a DI so I don't know for sure.

Leaking at expansion pipe flange clamp? I guess RTV is okay but copper ring crushing action is the real seal? It can be a challenge to get flanges perfectly straight and eliminate leaks, straight flanges is key. I guess the copper ring can be reused maybe but think new one is better?

Good luck!

Leaking at expansion pipe flange clamp? I guess RTV is okay but copper ring crushing action is the real seal? It can be a challenge to get flanges perfectly straight and eliminate leaks, straight flanges is key. I guess the copper ring can be reused maybe but think new one is better?

Good luck!

68ragtop

Well-Known Member

a couple years ago I was doing some maintenance work on one of my 2-stroke snowmobiles. I was looking at the piston crown for no real reason, but noticed there was almost no piston wash. It was running lean on both cylinders. Starting looking closer for the cause, I found a crack in the expansion pipe. Welded it up & everything cooled back down. Soooo, what I am getting at is, in 2-stroke sleds a leaking pipe can cause the engine to run lean & then you know what can happen.  I don't think a seadoo is any different.

I don't think a seadoo is any different.

I wouldn't run it much with an exhaust leak.

I wouldn't run it much with an exhaust leak.

Sportster-2001-951C-Stock

Well-Known Member

a couple years ago I was doing some maintenance work on one of my 2-stroke snowmobiles. I was looking at the piston crown for no real reason, but noticed there was almost no piston wash. It was running lean on both cylinders. Starting looking closer for the cause, I found a crack in the expansion pipe. Welded it up & everything cooled back down. Soooo, what I am getting at is, in 2-stroke sleds a leaking pipe can cause the engine to run lean & then you know what can happen.I don't think a seadoo is any different.

I wouldn't run it much with an exhaust leak.

Yes that makes perfect sense, seems like most bilge exhaust leaks tend to fill the bilge with carbon monoxide as well and the riders seat has to be removed for ventilation.

Thank you for this thread!! After my rebuild I've been doing a lot of troubleshooting. Even broke down and bought a CandooPro. It gave me P0166 I believe, which said "engine temperature out of range." Upon doing some research I stumbled on this thread and I too crossed the connectors on the Knock Sensor and Engine Temperature Sensor. What a relief to have my first rebuild actually running correctly. A DI seems like a terrible machine to start out with, but I've learned a lot.

Thanks again.

Thanks again.

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 511

- Replies

- 17

- Views

- 828

- Replies

- 23

- Views

- 1,908