colinkris1

Member

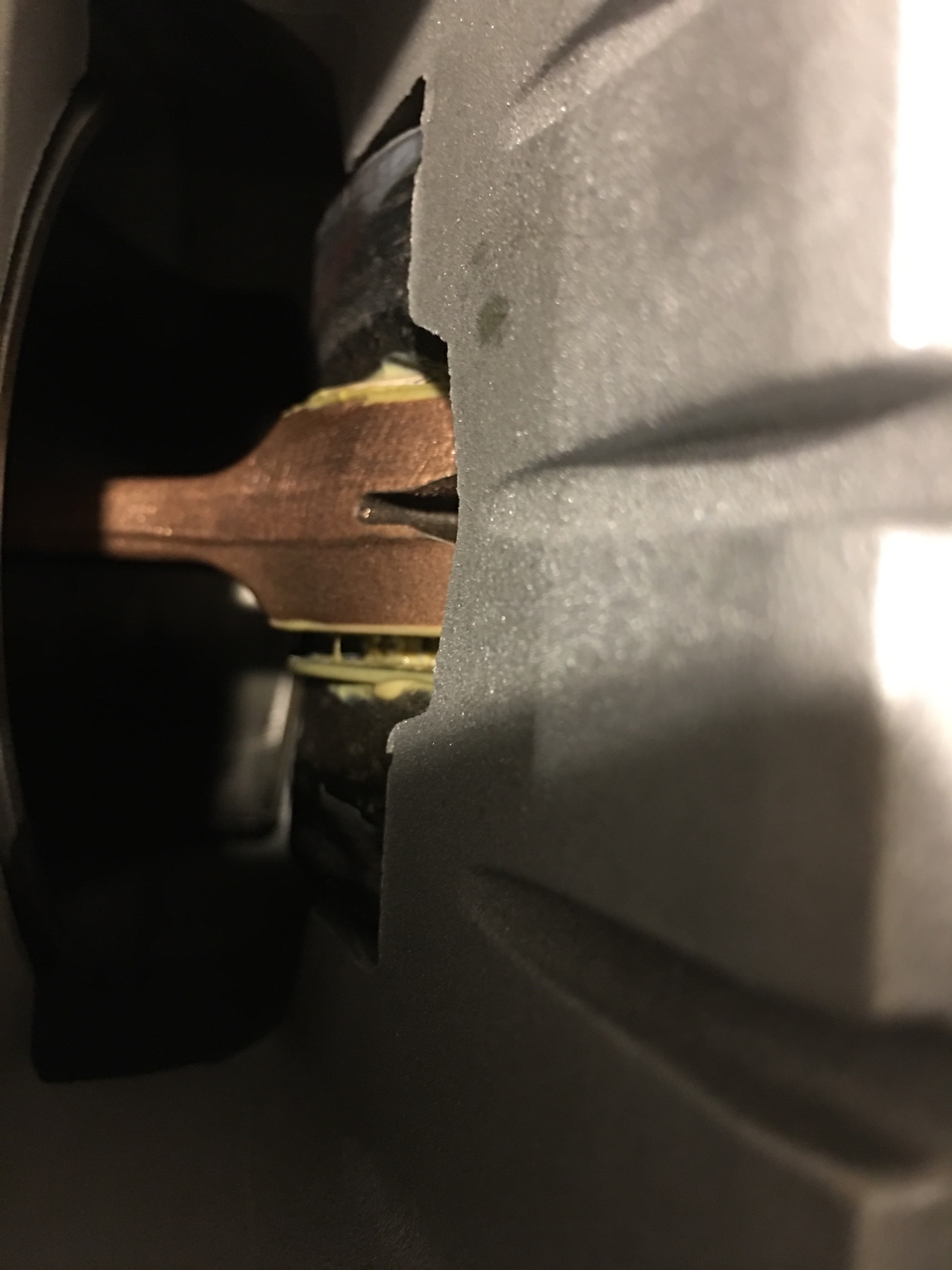

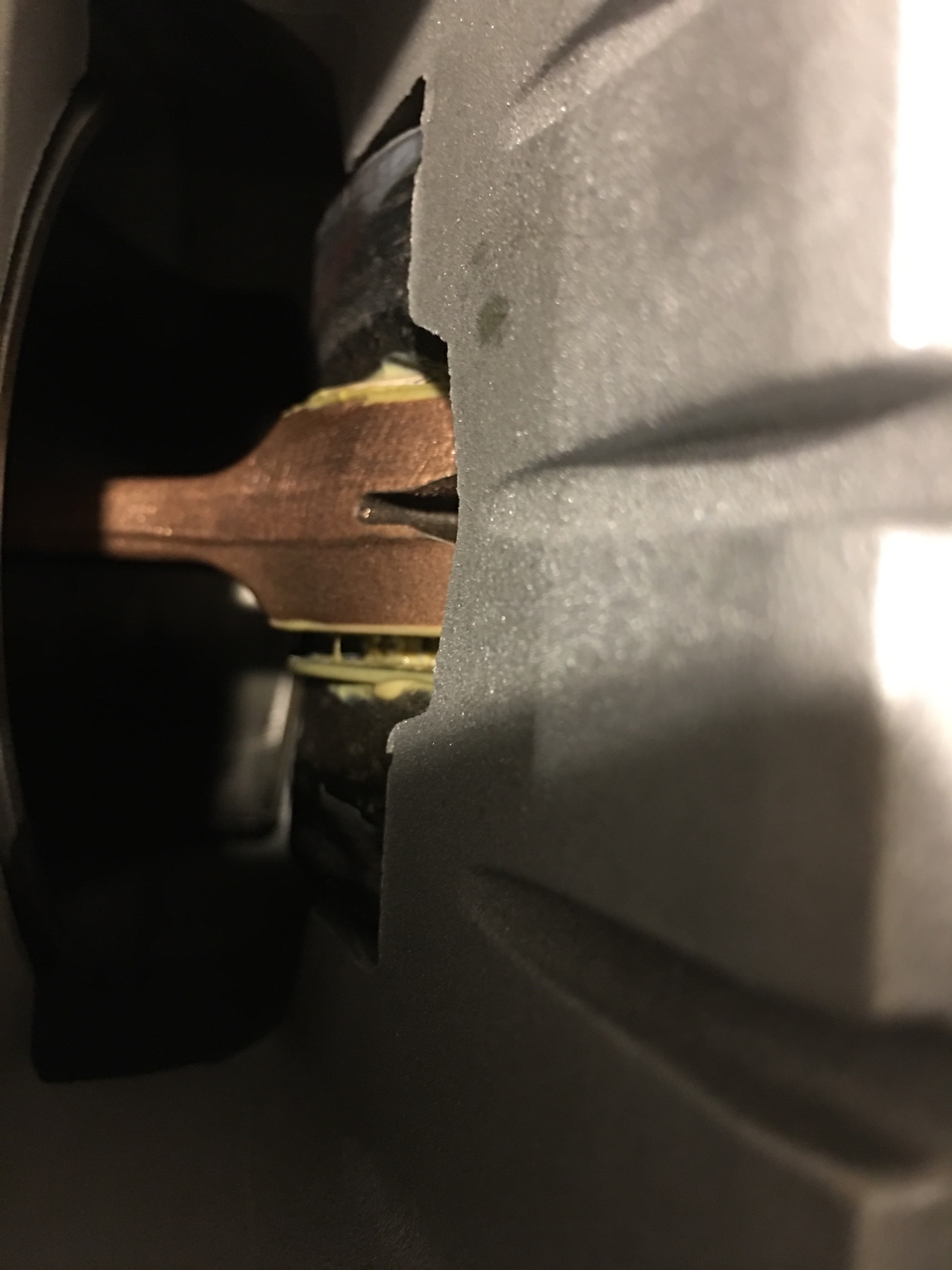

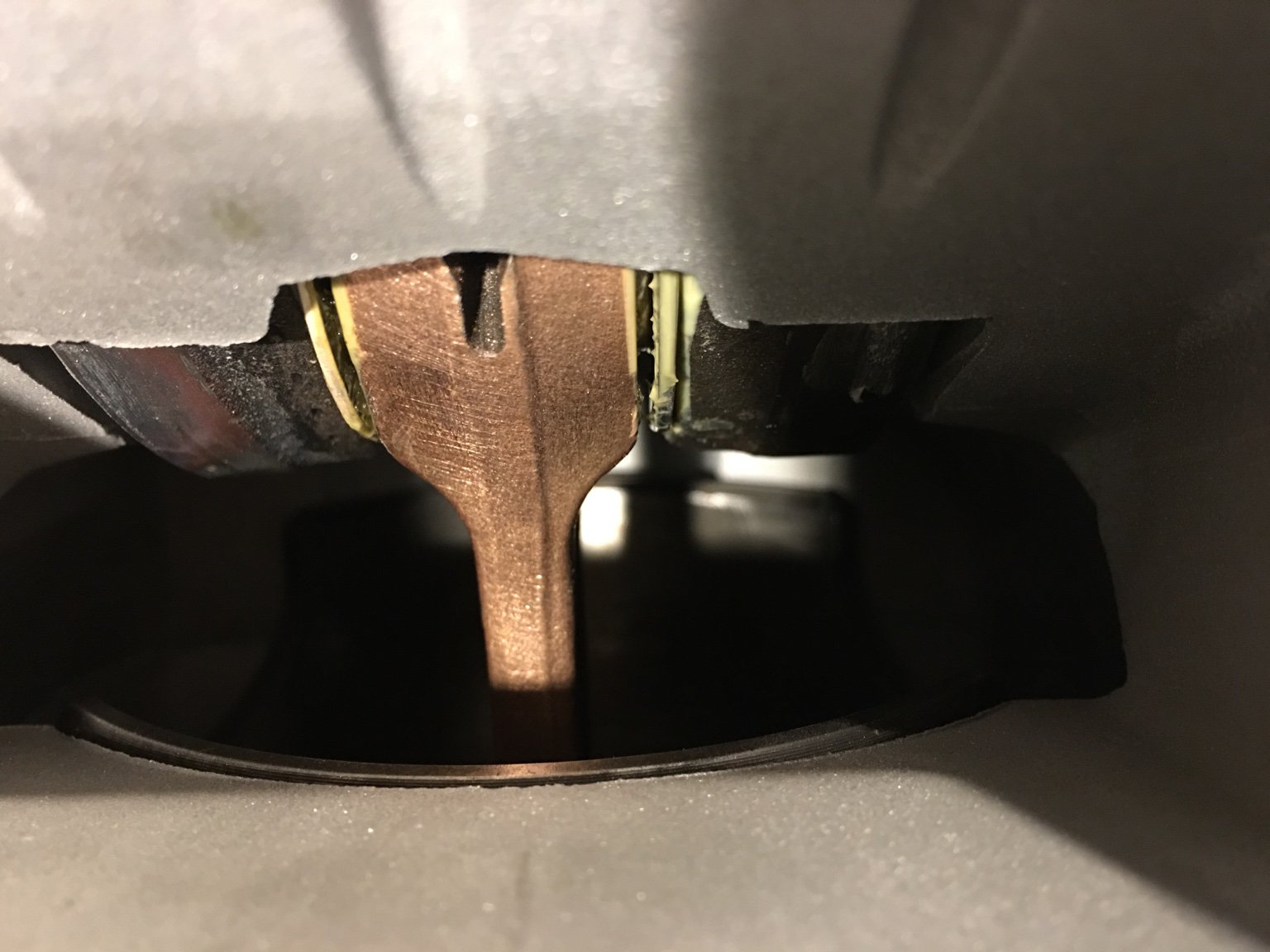

I got my 2 engines back (right on time) after the predicted 2 month turn around. 1 box check - sweet! The first arrived Friday and all looked good. Cylinder is bored .25 over. The second arrived Monday and I don't quite get the same warm fuzzy as I did with the first. It is bored .50 over. It also has what appears (to me at least) to be a rod that wasn't pressed tight enough? Also, it looks like they didn't put assembly grease on the other rod - just oil. The rods in the other engine both have lube and appear as tight as the one without lube pictured here. Also, is .25 in one engine and .50 in the other okay with stock jetting? Is this considered minimal boring over or a lot. No clue how much these can be bored and I've heard some shops just re-sleeve to stock specs. Please check out the pics and let me know.