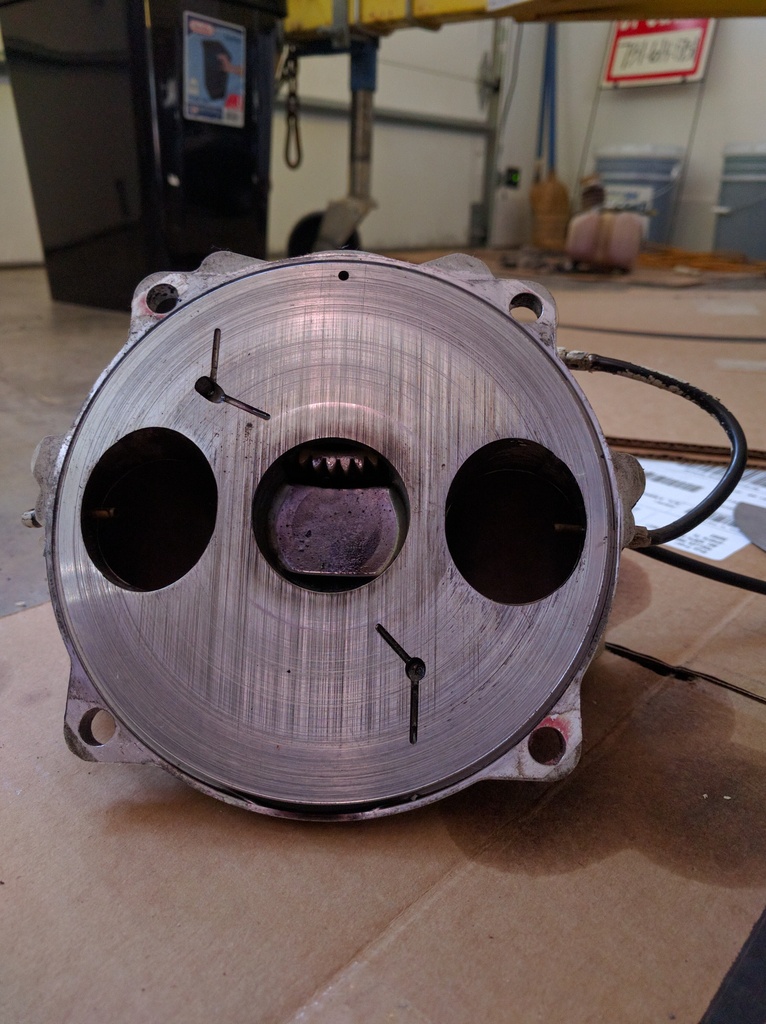

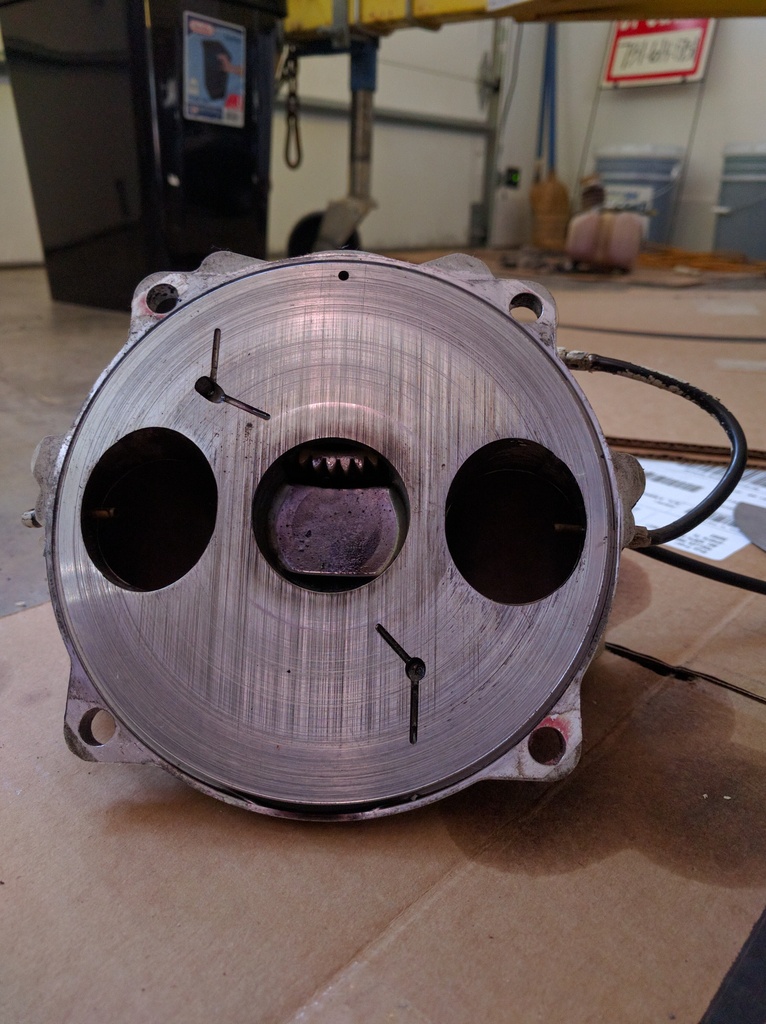

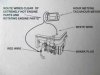

In the process of installing a SBT engine in my 96 GTi. Around 300-320 hours on it. At first look I figured the rotory valve and plate needed to be replaced but I figured I'd get a second opinion. It's not scored or dented or gouged, just what I would call typical wear, but I'm not sure what these are supposed to look like either.