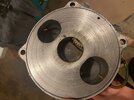

Hey everyone. In the middle of rebuilding a 717 out of my 97 season GTI, and whilst inspecting the used block that I ordered off eBay to replace my trashed one, I noticed a gouge in the block deck. Pictures are attached. What do y'all think? I've heard of guys filling gouges with high temp jb weld and sanding it level.

-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

Gouge in block deck

- Thread starter mtf0011

- Start date