Hey guys! Just had both my 787's rebuilt on my 99 speedster and I'm on premix, however my red light is on above my gas guage and I peeked at my oil tank and its about 20%. . Few questions..

Premix is in the gas and I have 1/2 tank left, how long should I run my tank before actually filling it with gas full tank?

I can just top off my oil tank with fresh genuine seadoo 2 stroke oil as it sits right now to make the light go away right?

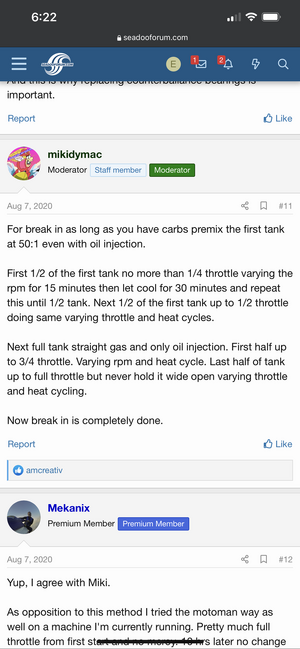

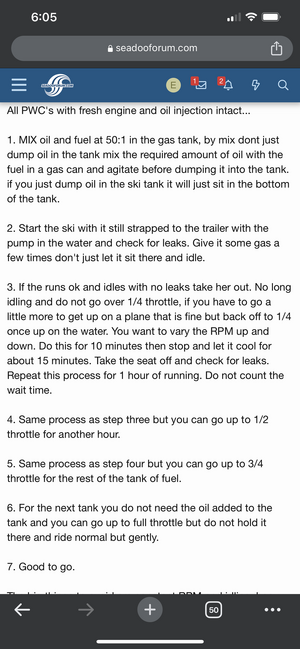

How long is break in period and what does it consist of? I'm getting/reading mixed answers.

Premix is in the gas and I have 1/2 tank left, how long should I run my tank before actually filling it with gas full tank?

I can just top off my oil tank with fresh genuine seadoo 2 stroke oil as it sits right now to make the light go away right?

How long is break in period and what does it consist of? I'm getting/reading mixed answers.

Last edited: