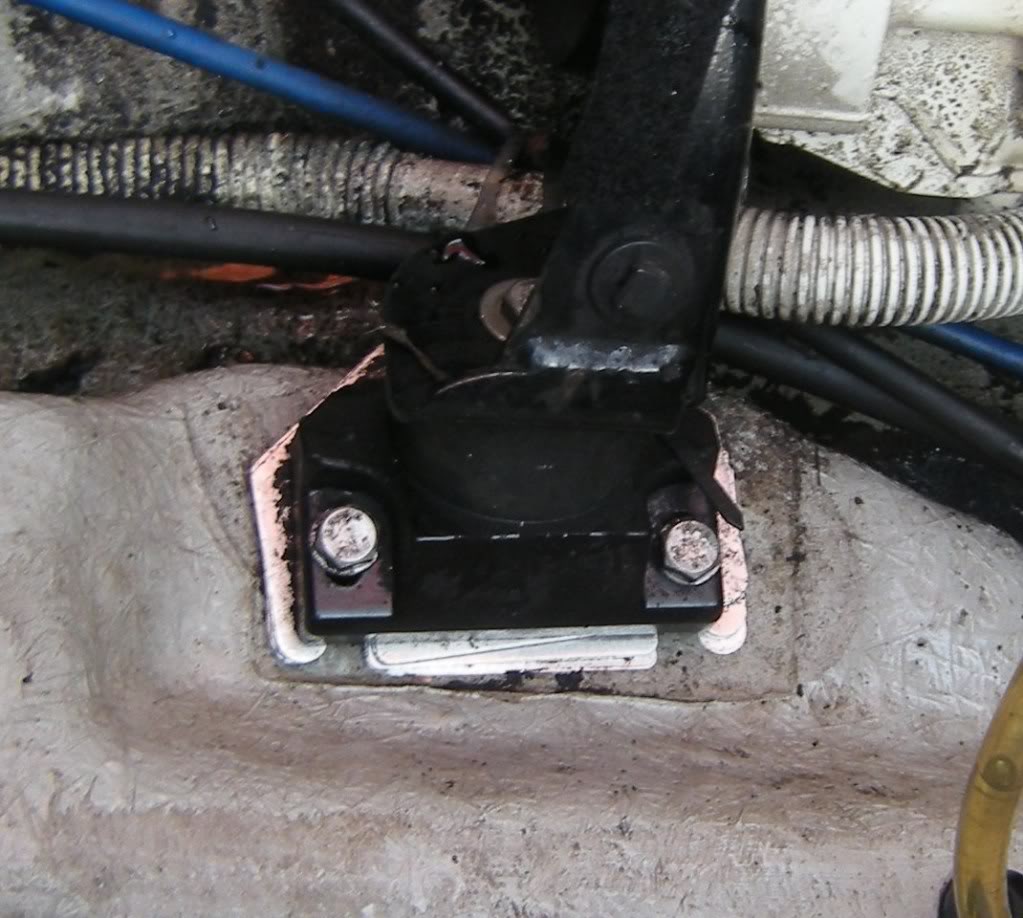

I hope you have better luck on yours than I did mine this past fall. For some reason, when I bought my boat, I found the pump had washers between the pump and hull, only on the top two studs. I found out why when I went to put my new motor in. With the 787 sitting on the bottom of it's engine mounts, with no shims, it already sat higher than the pump shaft. There was no way to "unshim" the mounts, so the only way to bring the shaft up to meet the PTO, was by using washers on the upper studs of the pump. This was the only way I could get alignment. In hindsight, I have to believe there may have been some damage to the fiberglass at the rear mounts, causing this. Normally, when you put the motor in, the drive shaft to pump will be lower at the PTO, so you have to shim the motor to lift up and meet the shaft. To be vice versa was a pain to work with.

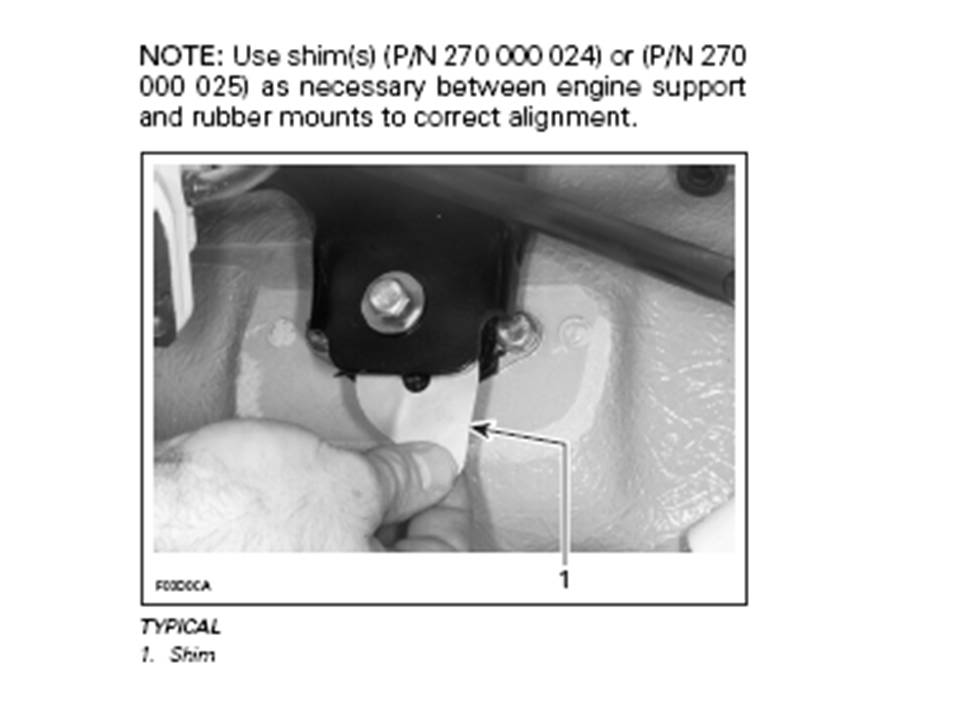

When you set up your alignment tool, you'll bolt the plate to the hull, flat out. Then, when you drop your motor down on top of your mounts, you'll push the alignment tool in to meet the PTO. Seeing where that shaft meets your PTO, will tell you where to shim the motor. You will be looking for the shaft to meet and recess into the PTO without any deflection. Don't worry if it's not perfect. The Rotax shaft was designed with a rounded edge at the end. That was to take up for slight differences in the alignment. But, do your best to get it as close as possible. If it's off too bad, you'll know from the excessive vibration. Cheers!