Riverguy42

Member

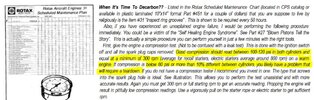

While scouring the web looking for compression specs and test procedures actually published by Bombadier or Rotax, the interesting thing is that the ONLY place I can find these is in the maintainence manuals for the 2-stroke Rotax AIRCRAFT engines. This might be because the FAA forces aircraft engine manufacturers to do this, but why would Rotax keep this 'confidential' for Jet Boats and PWC?

My factory Sea Doo shop manual (1996 Sportster/Speedster/Challenger) does not specify either the psi numbers, nor the correct procedure for testing.

From the Rotax aircraft manuals I'm seeing minimum acceptable numbers of 80-87psi. The highest 'minimum' number I can find is 100psi from an authorized Rotax Aircraft Engines dealer in California, who also says "below 80 psi is time for top-end rebuild". The same dealer says the top of the 'good' range is 120psi while cranking a warmed-up engine at a minimum of 300rpm.

I can't find any reference to any compression spec above 120PSI.

Here and on the various PWC websites I'm reading things like "150/150 is perfect and 120 it’s toast". Where are these higher numbers coming from, and what is the procedure for getting them? Also, several posts have raised the question as to why Sea Doo doesn't specify what the compression numbers should be?

I was seeing 123/125 on my new-to-me Rotax 717 (1996 Sportster). I used a precision pressure gauge to verify the calibration of my compression tester and battery was strong and cranking very fast, throttle wide open, engine was warm.

After reading "...and 120 it's toast" I was getting ready to do a top-end teardown, but now I am reading that these numbers are 'perfect'. Likewise, the nearby Sea Doo dealer says 120 psi is about right for these engines when new. With a new impeller and wear ring it's running perfectly, topping out at ~43mph.

Can anyone say where these 150 psi numbers are coming from, and what is the detailed proceedure for getting them?

My factory Sea Doo shop manual (1996 Sportster/Speedster/Challenger) does not specify either the psi numbers, nor the correct procedure for testing.

From the Rotax aircraft manuals I'm seeing minimum acceptable numbers of 80-87psi. The highest 'minimum' number I can find is 100psi from an authorized Rotax Aircraft Engines dealer in California, who also says "below 80 psi is time for top-end rebuild". The same dealer says the top of the 'good' range is 120psi while cranking a warmed-up engine at a minimum of 300rpm.

I can't find any reference to any compression spec above 120PSI.

Here and on the various PWC websites I'm reading things like "150/150 is perfect and 120 it’s toast". Where are these higher numbers coming from, and what is the procedure for getting them? Also, several posts have raised the question as to why Sea Doo doesn't specify what the compression numbers should be?

I was seeing 123/125 on my new-to-me Rotax 717 (1996 Sportster). I used a precision pressure gauge to verify the calibration of my compression tester and battery was strong and cranking very fast, throttle wide open, engine was warm.

After reading "...and 120 it's toast" I was getting ready to do a top-end teardown, but now I am reading that these numbers are 'perfect'. Likewise, the nearby Sea Doo dealer says 120 psi is about right for these engines when new. With a new impeller and wear ring it's running perfectly, topping out at ~43mph.

Can anyone say where these 150 psi numbers are coming from, and what is the detailed proceedure for getting them?