Kingsspeedshop

Active Member

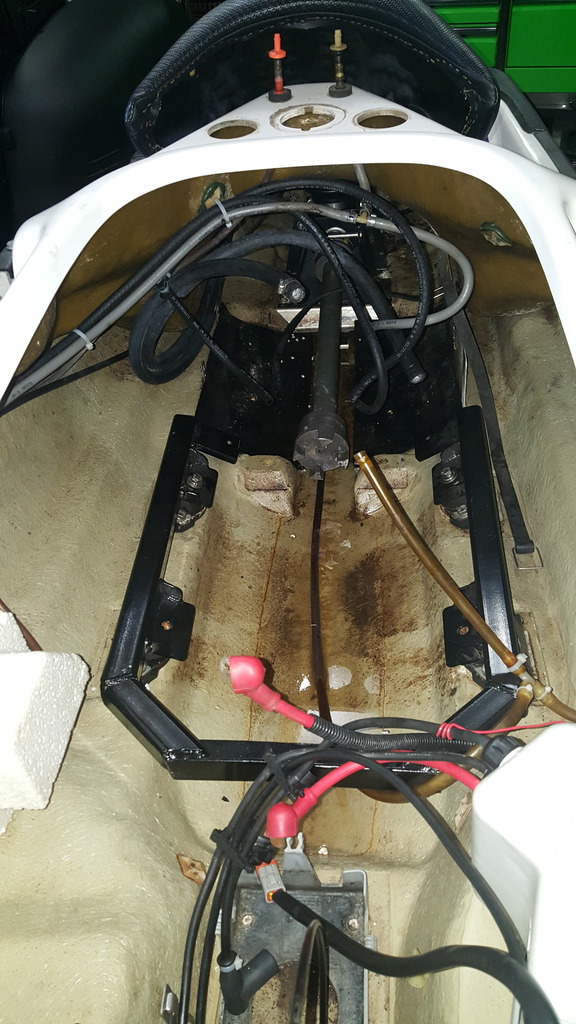

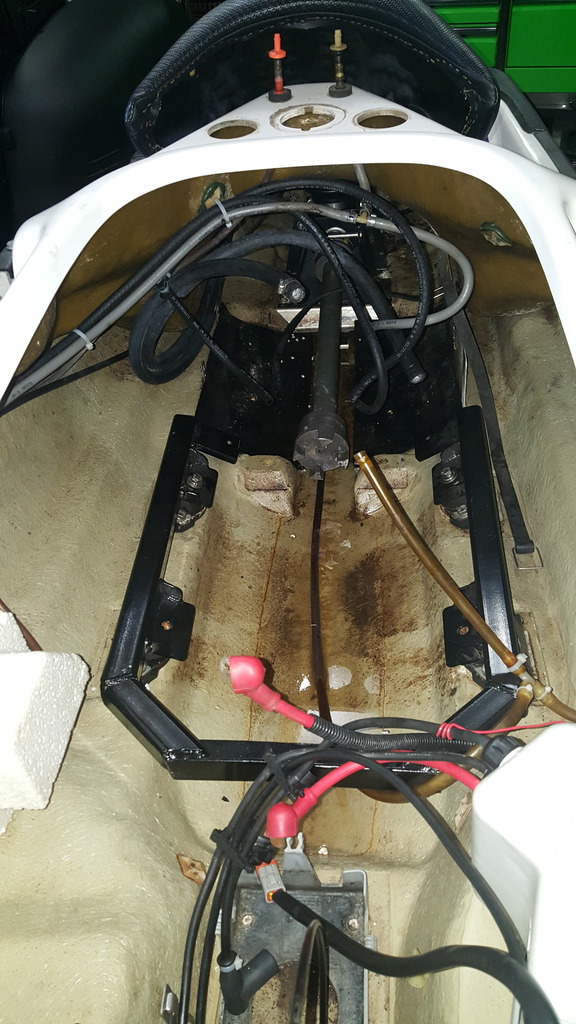

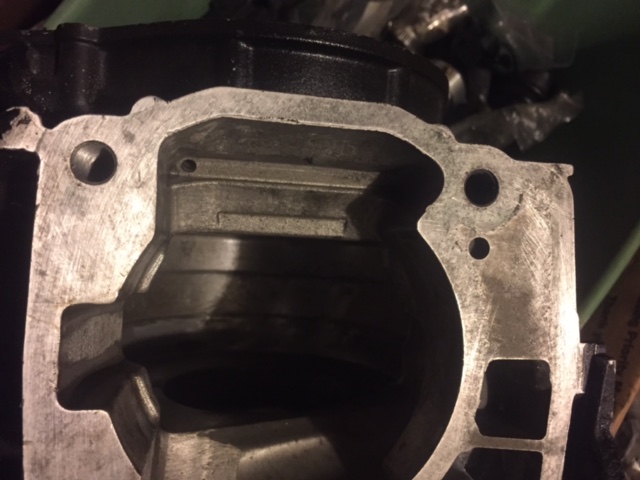

Well I have been going to the races for quite a few years as a spectator!. Always loved the sound and smell. Anyways This 2017 season I will be a racer for the first time. Was talking to Matt Braley one day about racing and building a ski to compete. Long story short he was on board and excited like I was! The class we will be running in will be Sport GP on the ProWatercross tour. The ski that we will be building is my Resto HX ski I got from backwoods AL called "Field of Dreams". The ski already has quite a few race inspired parts on it so its a good candidate. Matt will be building a fully ported superstock 787 from the ground up. Yes you heard right a 787. i know this class is running fully modded Kawi Triples but with Matt's knowledge and my riding skills I think we will be quite competitive. Over the holidays I got a head start on stripping the ski of parts we will not be using. All of the stuff on the ground will not be used besides the gas tank and a couple of hoses.