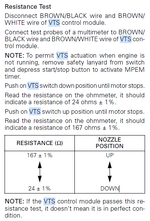

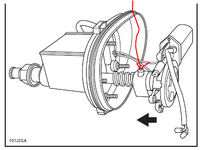

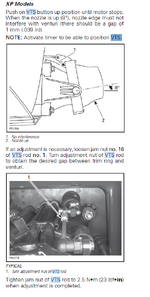

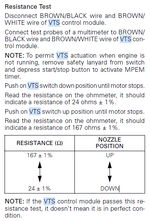

I just picked up and got running a 96 xp for 600$. Hadn’t been licensed since 2016. As the title states my vts gauge is wrong. It goes up and down with the trim but at all the way up, on the gauge it shows just barely more than all the way down. With trim down, on the gauge it’s way below down. Would be awesome if anyone had any ideas what to look for there.

Side note. The fuel gauge doesn’t work, but I know what to look for there. I Assume from past experiences the speedo doesn’t work iether but haven’t took it out yet

It appears someone put a new sbt engine in it before letting it sit for 10 years. 160 on one cylinder and 170 on the other. It’s spraying water out underneath the manifold as well as from one of the exhaust plugs. hoping it’s the manifold gasket and I don’t have to pull the cylinder.

I’ve done the carbs, removed all old fuel and oil, replaced oil lines, new starter+solenoid, new wear ring, new carbon seal, new vts boot, and prolly more I’m not thinking of. It already had fuel lines replaced. Someone let me know if they can think of anything else I should check.

Very excited to ride it after all I’ve heard about them.

Side note. The fuel gauge doesn’t work, but I know what to look for there. I Assume from past experiences the speedo doesn’t work iether but haven’t took it out yet

It appears someone put a new sbt engine in it before letting it sit for 10 years. 160 on one cylinder and 170 on the other. It’s spraying water out underneath the manifold as well as from one of the exhaust plugs. hoping it’s the manifold gasket and I don’t have to pull the cylinder.

I’ve done the carbs, removed all old fuel and oil, replaced oil lines, new starter+solenoid, new wear ring, new carbon seal, new vts boot, and prolly more I’m not thinking of. It already had fuel lines replaced. Someone let me know if they can think of anything else I should check.

Very excited to ride it after all I’ve heard about them.