Hello guys, first post so please bare with me haha.

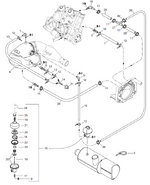

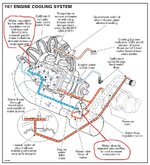

So I bought a 96 XP about a month ago. PO said he rebuilt the carbs and got new pistons in it. Right out of the gate the ski ran fine, in my opinion, then again I am new to two-strokes so maybe I’m missing something? After looking further into it I noticed the ski was missing a flame arrestor “grill” I ordered a new one and placed it into the air box along with a new air box cover and latches. After a couple times of riding after said repairs I started to notice that the exhaust hose from cone into water box melted a hole into it. I read up on the forums and noticed people kept mentioning the WRV, so I replaced that with a whole new assembly, including replacing the wire clip for the bellow with a ziptie, and of course added a new OEM exhaust hose. Took the ski out for another test and sure enough the hose started to bubble again… I unplugged the top hose from the WRV going to the caled’ fitting in the tuned pipe while the ski was on and it was shooting water out and the pisser is shooting out fine while idling and cruising, both the engine block and top side of tuned pipe are cool to the touch but the water box and cone are scorching hot… I checked all cooling lines for blockages and none were found, I also checked the calibrated fitting going into the tuned pipe from the WRV and it seemed fine? I blew into it and got some resistance but I’m guessing it’s because the caled’ fitting has a smaller opening than the others? I ordered a new one just to make sure along with the proper loc-tite. Correct me if I’m wrong… Anyway, I’m completely at a loss and wanted to get some opinions from people who have WAY more experience than me.

So I bought a 96 XP about a month ago. PO said he rebuilt the carbs and got new pistons in it. Right out of the gate the ski ran fine, in my opinion, then again I am new to two-strokes so maybe I’m missing something? After looking further into it I noticed the ski was missing a flame arrestor “grill” I ordered a new one and placed it into the air box along with a new air box cover and latches. After a couple times of riding after said repairs I started to notice that the exhaust hose from cone into water box melted a hole into it. I read up on the forums and noticed people kept mentioning the WRV, so I replaced that with a whole new assembly, including replacing the wire clip for the bellow with a ziptie, and of course added a new OEM exhaust hose. Took the ski out for another test and sure enough the hose started to bubble again… I unplugged the top hose from the WRV going to the caled’ fitting in the tuned pipe while the ski was on and it was shooting water out and the pisser is shooting out fine while idling and cruising, both the engine block and top side of tuned pipe are cool to the touch but the water box and cone are scorching hot… I checked all cooling lines for blockages and none were found, I also checked the calibrated fitting going into the tuned pipe from the WRV and it seemed fine? I blew into it and got some resistance but I’m guessing it’s because the caled’ fitting has a smaller opening than the others? I ordered a new one just to make sure along with the proper loc-tite. Correct me if I’m wrong… Anyway, I’m completely at a loss and wanted to get some opinions from people who have WAY more experience than me.

Last edited: