A few months ago I bought a 98 Sportster 1800. I knew it would need work but didn't realize how bad it really was. I have decades of automotive mechanical and fabrication background but not a single day of boat experience. I bought this boat because it was cheap, had mostly good, new upholstery, and supossedly two new engines. If I had any experience in Sea Doos at all I would have ran away from it as fast as I could. Be that as it was, 2 new engines, virtually every mechanical component replaced, months of electrical trouble-shooting, and thousands of dollars later, (all done by me) it is running great and my wife, daughter, and I were able to still get out on the water for a few days before the season ended. I live on the Gulf in FL so I'm sure we'll still go out on warm winter days as well.

During the mechanical repair process I quickly realized that I was missing tons of crap from the boat. It became apparent that I needed a parts boat. I also realized that the rear seats were not OEM. The PO had replaced the original bench seat with 2 aftermarket bucket seats that were too tall and made it difficult to fit my legs under the dash. Once I got them under there, any bumps resulted in bruised and painful knees. So when I found a parts boat with a salvageable bench seat and a better trailer than I had, I snatched it up for $1000. It has paid for itself exponentially through this process as I've used almost every component from it except the hull.

Now that winter is here I am starting the project of replacing these aftermarket seats with an OEM bench again. These benches are not easy to find so I am having to work with what I got out of my parts boat. The parts boat sat outside in the woods for 13 years before I got to it. Almost every seat in it was completely rotted and un-salvageable EXCEPT the bench seat. While rough, I knew I could save it. I am not an upholstery guy, but I have worked with foam and upholstery on a couple automotive applications in the past. So while I have some direction of where to go with this, advice is also appreciated.

I forgot to get a pic of my seat bottom before removing the wrecked upholstery. But here's the back:

It was in the better shape of the two. I removed probably about 1000 staples to get the rotten upholstery off using this tool from Lowe's:

Here's the armrests before I stripped them:

And here's everything after I got all the rotted upholstery off:

Like I said, these are rough, but salvageable. One other thing. The rivnuts that these things are held on with SUCK! Two of them spun in the plastic backs instead of the bolt coming out. I had to use a grinder to cut the bolt of the head off:

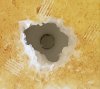

I plan to replace these with something that won't spin in the future. To get at them the foam has to be separated from the Styrofoam backing. It's just glued on with a light spray-adhesive and peels right apart:

I simply pushed the cut-off bolt and loose rivnut through the Styrofoam backer. It leaves a small hole but it won't affect anything. I'm open to suggestions as to what to replace these rivnuts with.

To glue the foam back on I'll use 3M spray adhesive, which works awesome with foam and plastics. You spray both surfaces, let it dry to a tacky state (about 5 minutes) and then stick everything back together.

I think there's a 10-pic limit so I'll continue in another post ...

During the mechanical repair process I quickly realized that I was missing tons of crap from the boat. It became apparent that I needed a parts boat. I also realized that the rear seats were not OEM. The PO had replaced the original bench seat with 2 aftermarket bucket seats that were too tall and made it difficult to fit my legs under the dash. Once I got them under there, any bumps resulted in bruised and painful knees. So when I found a parts boat with a salvageable bench seat and a better trailer than I had, I snatched it up for $1000. It has paid for itself exponentially through this process as I've used almost every component from it except the hull.

Now that winter is here I am starting the project of replacing these aftermarket seats with an OEM bench again. These benches are not easy to find so I am having to work with what I got out of my parts boat. The parts boat sat outside in the woods for 13 years before I got to it. Almost every seat in it was completely rotted and un-salvageable EXCEPT the bench seat. While rough, I knew I could save it. I am not an upholstery guy, but I have worked with foam and upholstery on a couple automotive applications in the past. So while I have some direction of where to go with this, advice is also appreciated.

I forgot to get a pic of my seat bottom before removing the wrecked upholstery. But here's the back:

It was in the better shape of the two. I removed probably about 1000 staples to get the rotten upholstery off using this tool from Lowe's:

Here's the armrests before I stripped them:

And here's everything after I got all the rotted upholstery off:

Like I said, these are rough, but salvageable. One other thing. The rivnuts that these things are held on with SUCK! Two of them spun in the plastic backs instead of the bolt coming out. I had to use a grinder to cut the bolt of the head off:

I plan to replace these with something that won't spin in the future. To get at them the foam has to be separated from the Styrofoam backing. It's just glued on with a light spray-adhesive and peels right apart:

I simply pushed the cut-off bolt and loose rivnut through the Styrofoam backer. It leaves a small hole but it won't affect anything. I'm open to suggestions as to what to replace these rivnuts with.

To glue the foam back on I'll use 3M spray adhesive, which works awesome with foam and plastics. You spray both surfaces, let it dry to a tacky state (about 5 minutes) and then stick everything back together.

I think there's a 10-pic limit so I'll continue in another post ...

Last edited: