WhiskeyD

Well-Known Member

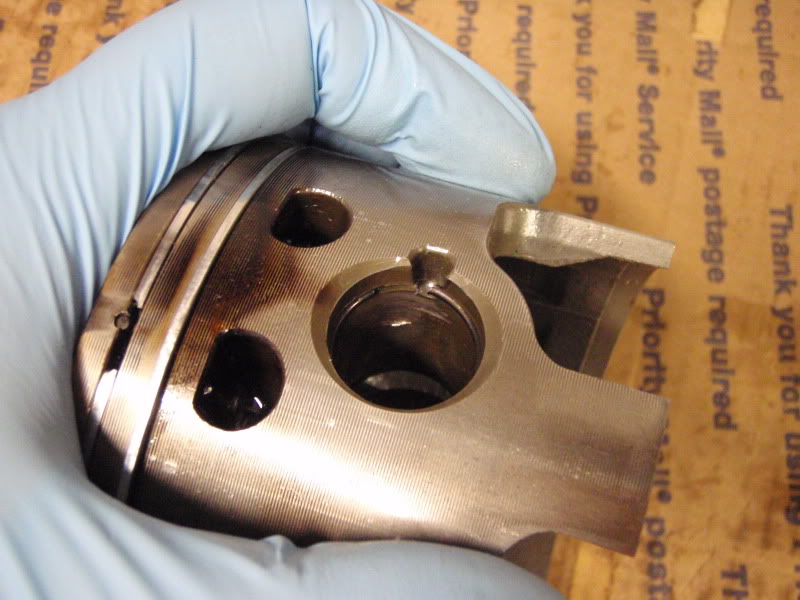

I'm finally getting around to rebuilding the 717 and I cannot for the life of me get the circlips installed. I've broken both thumb nails and tried working it in with a flat head with no luck. I searched around and people said to put the open end first at 6oclock and work your way up the sides and it will snap into place. Well I cant even get the open end into the groove. Before getting mad and giving up I did manage to barely get the open end into the groove once but the clip popped back out before fully going into the groove and now its very slightly an oval shape compared to the others. The clips are rigid and larger than the groove (of course since they compress). They are the ones that came with the WSM kit so I know they are the right ones. I bought some circlip pliers but they are worthless on these clips since they dont have holes at the opening. Any tips on installing these? I've installed circlips in the past but damn they were no where near as hard as these... and I didn't have a broken finger at the time :cuss:

Last edited by a moderator: