SeaDooDoo90

Member

The PO of my '97 SPX said he recently had the jet pump unit rebuilt by a mechanic. This "mechanic" was far from a professional though as his solution for fixing a broken jet pump fitting was silicon-ing at and around the two halves (yes, the ski leaked horribly the first time I launched it, but fortunately I kept it on the trailer).

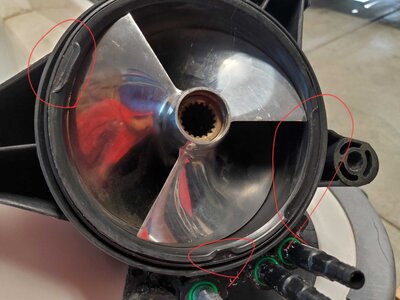

I've extracted the broken OEM plastic fitting and replaced it with an aluminum one from WSM. I'm looking at the wear ring now and it looks off. The lip of it that mates to the neoprene seal against the hull is folded over in a few areas.

Will those folds cause me cavitation issues? At a minimum, should I try trimming down those areas so they don't hang into the channel of the pump as much?

I've extracted the broken OEM plastic fitting and replaced it with an aluminum one from WSM. I'm looking at the wear ring now and it looks off. The lip of it that mates to the neoprene seal against the hull is folded over in a few areas.

Will those folds cause me cavitation issues? At a minimum, should I try trimming down those areas so they don't hang into the channel of the pump as much?