So after all my problems finally getting fixed, I took the sea doo for a rip twice, right in the morning everything was working.

I went up to get some breakfast, then came back down an hour later, and my VTS stopped working, when it was working that morning.

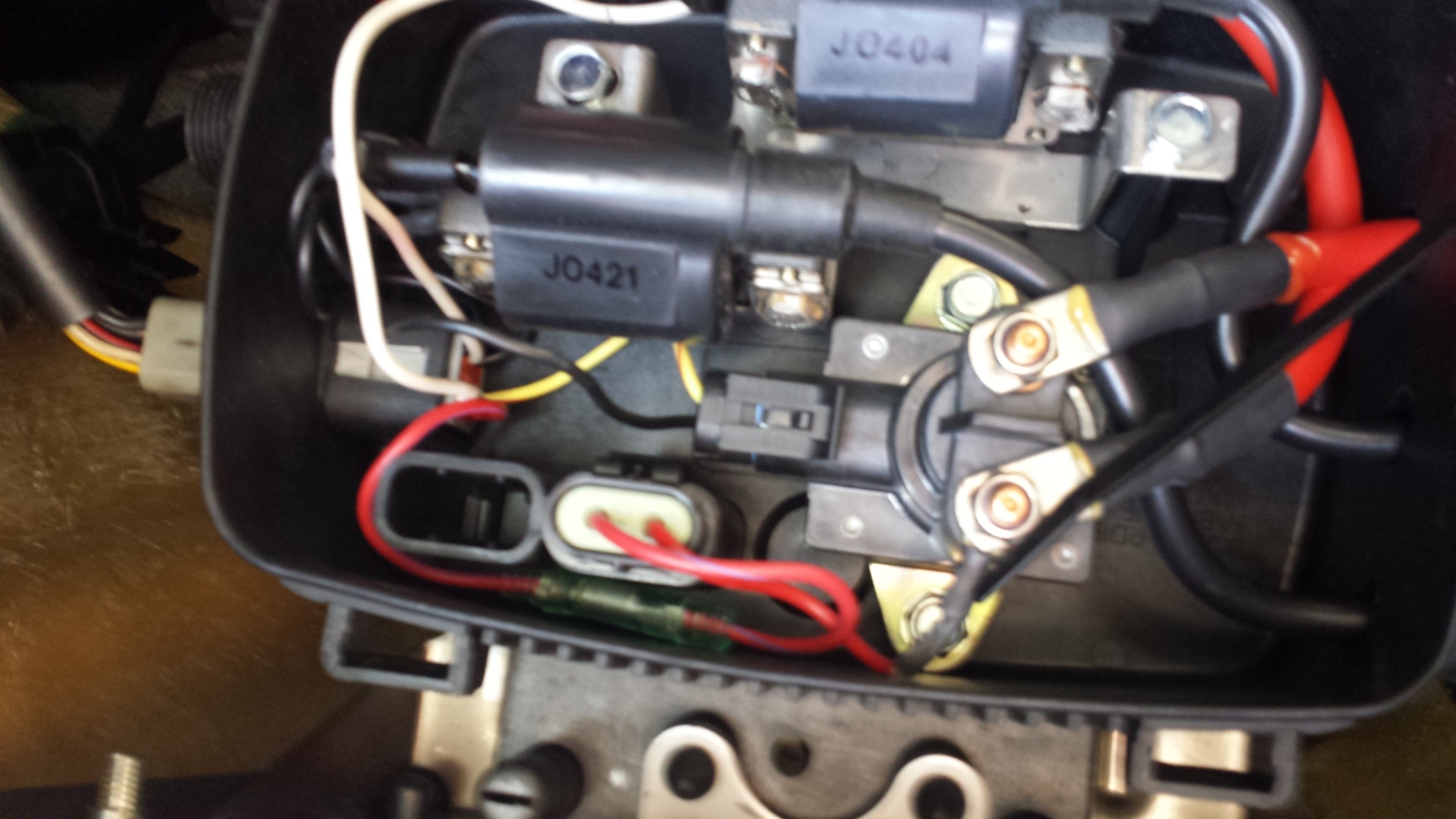

If I open the seat amd hit the VTS, I can hear some type of electrical noise trying to do something, but wont change on the guage or the back...

I went up to get some breakfast, then came back down an hour later, and my VTS stopped working, when it was working that morning.

If I open the seat amd hit the VTS, I can hear some type of electrical noise trying to do something, but wont change on the guage or the back...