An update....

What would be your next step be if you were in my situation?

I had my 951 carb engine rebuilt earlier this year at a cost of $2k (included shipping). I got 15 hours out of the engine before it started having problems. I broke the engine in using premix for the first tank, etc.

It was discovered that water was getting into the cylinders under the head gasket. I have pictures of this. It was not coming in from the pipe gasket. I pulled the engine from the boat.

After discussing the situation with the builder, we thought I could put everything back together since it was unlikely any of the new parts had worn significantly. After taking the top end off, I had a local machine shop deck the head and cylinder. He didn’t need to take much off, but said the inner portions of each were lower than the outer edges, so I’m glad I had this done.

The builder sent me a seal kit to put everything back together. I didn’t split the case since everything seemed fine with the new crank that was installed. I put everything back together, but the engine is still making the horrible sound after running it. There’s no water getting into the cylinder. See Youtube clip below. This was taken prior to pulling the engine, but the sound is the same.

Engine Stats:

Engine passed leak down tests for cooling system and engine.

Squish – I wasn’t able to get a reading after pulling the engine and measuring, so this was out of spec when it was rebuilt. After the head and cylinder was decked, I was able to get .9 and .91, so it should be within tolerance now.

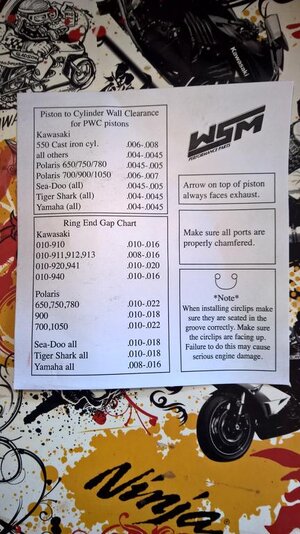

Cylinder wall clearance – Mag was in spec .4-.5, PTO was out of spec at .6. WSM pistons were used. I had the machine shop measure these.

Ring Gap – Mag was in spec at .18, PTO out of spec at .22.

Carbs – accel pump was removed, 90 low speed jets installed (1.5 turns out), stock high speed (0 turns out).

Here’s the clip (same as first post):

https://youtu.be/6gYpwY7tK7s

So, what would you do next to find the problem?