FlyinFred

Member

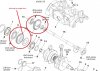

1997 seadoo XP (787) Long story short. I neglected to put locktite on the bolts that attach the spark aresstor housing to the carbs and guess what. a bolt came off and got injested. Tooks a lot of investiagtion by my son and I and it was not until i told him to take off the 4 bolts and he tells me there are only 3. That explains why the Seadoo locked up. Going to split the case and see what happened but my theory is that the bolt is caught in the two gears in picture 1. I will post more pictures once I get into the case.

1. Loctite is important!

2. Any reccomendations for an engine rebuilder in Arizona (or I can ship to)?

3. Anyone have a 787 engine for sale?

1. Loctite is important!

2. Any reccomendations for an engine rebuilder in Arizona (or I can ship to)?

3. Anyone have a 787 engine for sale?