FlyboyX

Active Member

Well, first of all, I am really excited to be a new member here. We just bought a new to us boat and I have so many questions.

First, over the course of internet searches for manuals and parts, I can never seem to find my model.

it is a 2000 Challenger 14' with twin Rotax Ybcxm engines listed on the placard as 718.3 cubic centimeters. The vin is cecb08471k900. Are these 717 or 720 Rotax engines or are they something entirely different that the company tried and failed at for only a year or so? I called the dealer. they looked up the vin, but I got the impression they are pretty clueless about a boat this old.

any search I do for a "2000 sea-doo challenger" only results in boats with a 6 cylinder Mercury 2 stroke engine. any search I do a year or two earlier only results in the 1800 model.

I've literally spent hours searching.....What the heck am I doing wrong? I know my boat isn't an anomaly.

this is my first experience with a sea-doo or a Rotax but I've had several boats in the past and I have a ton of experience fixing all things mechanical.

I have tons of other questions.....I just don't know where to begin.

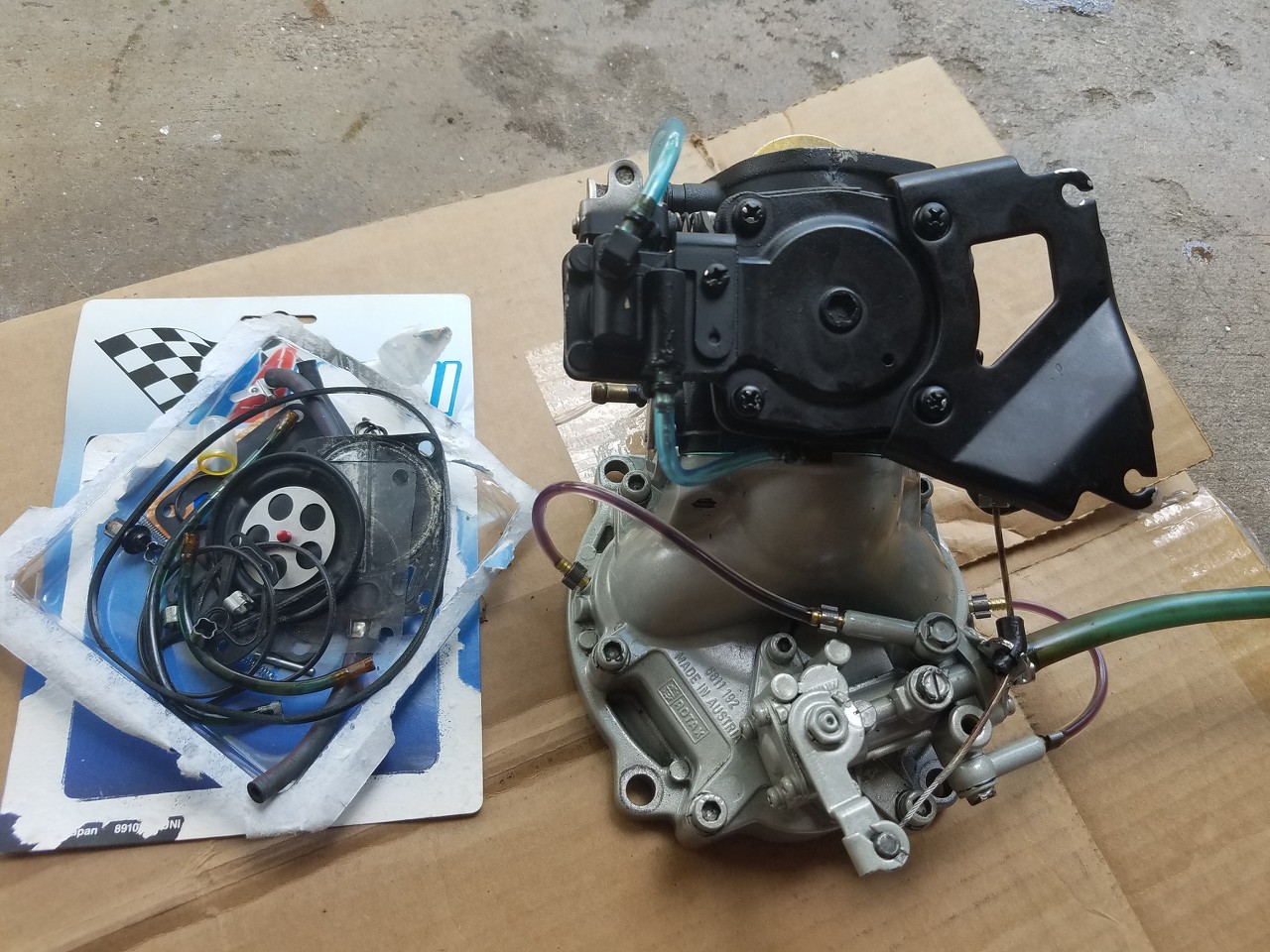

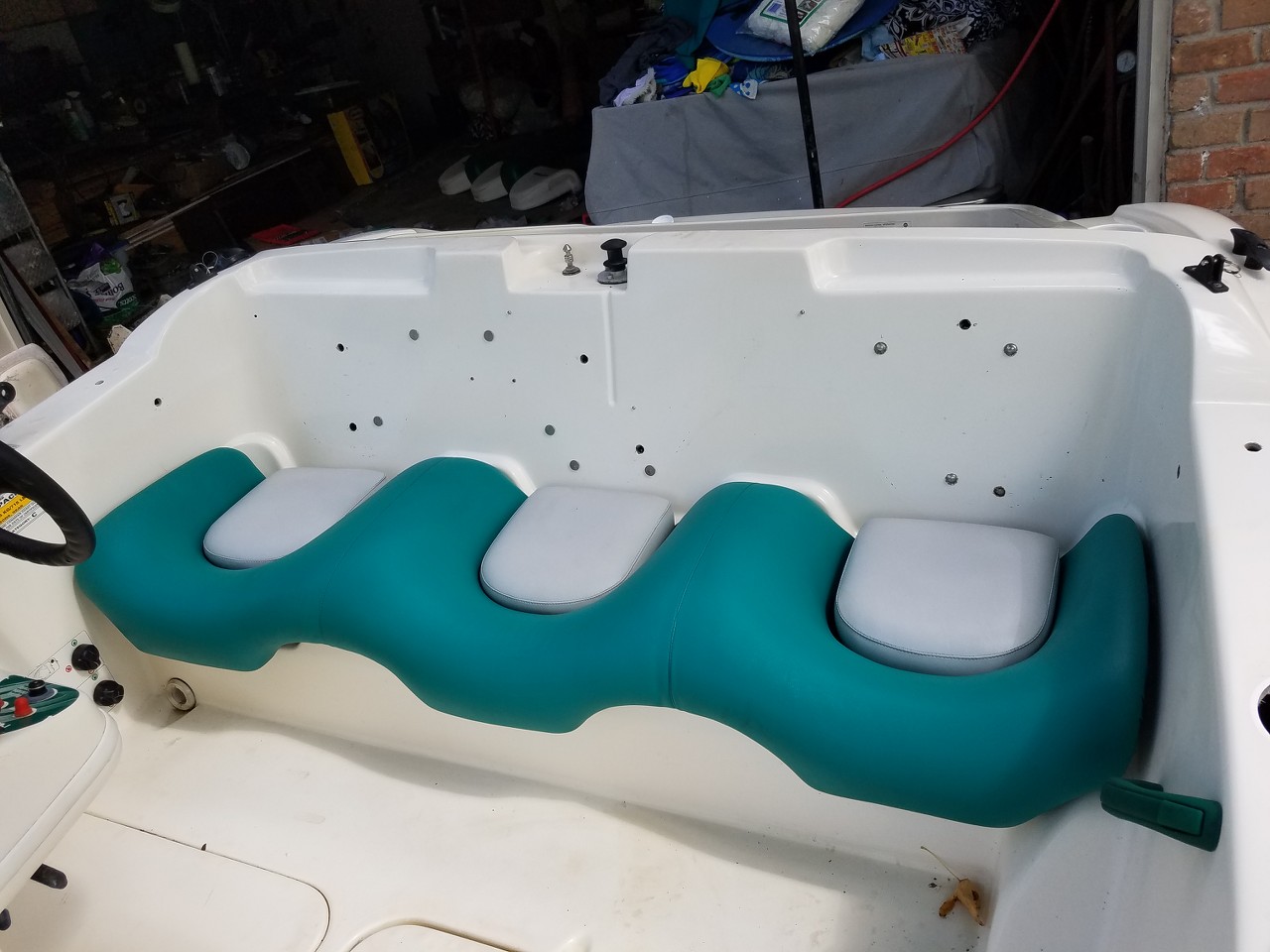

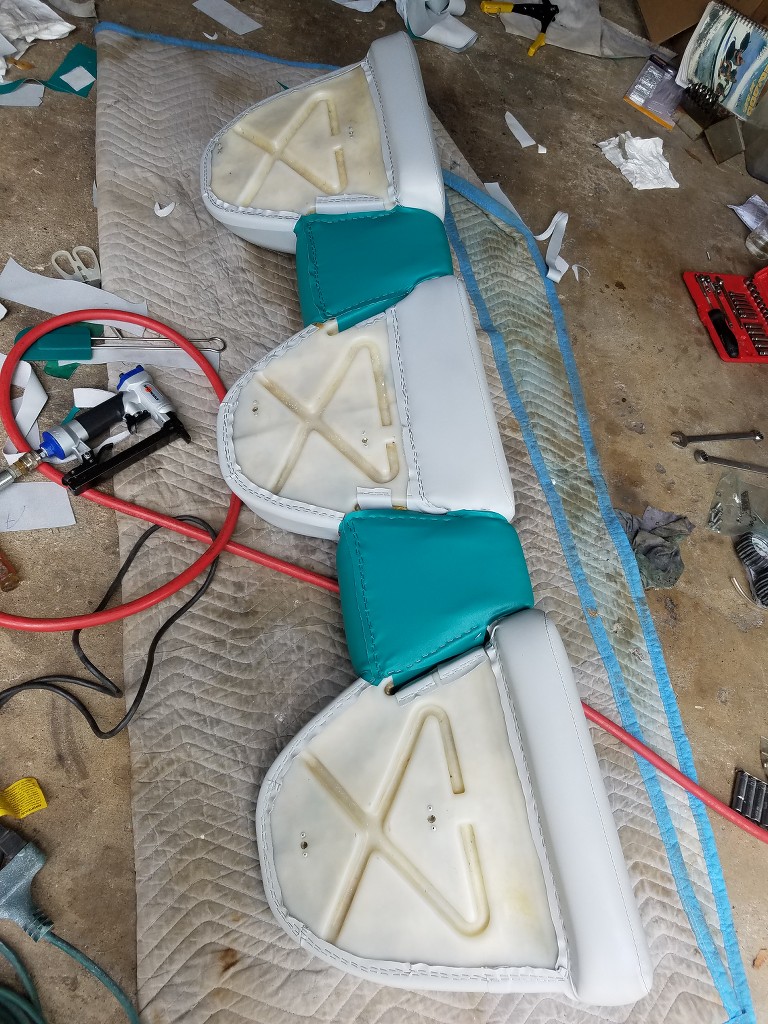

This boat has really low hours (maybe 50-100), has never been in salt, but has been sitting for perhaps 4 years. All 4 cylinders have 150+lbs of compression. they are original to the boat with shiny silver paint. they have never been taken apart but the carburetors appear to have been removed previously. so far, the carbs are off pulled off to be rebuilt. the oil tank and fuel cell have been drained. I pulled off the outdrives today and found I need a shaft protector and 2 shaft seals.

I want to replace the spark plugs and bleed the air out of the oil system since I took it apart. there are about a dozen or so minor parts I have written in my notebook that I need to replace. I just wish I knew where to look?

why is this so difficult for me? anyone with advice and a willingness to steer me in the right direction would be greatly appreciated.

regards,

Brian

First, over the course of internet searches for manuals and parts, I can never seem to find my model.

it is a 2000 Challenger 14' with twin Rotax Ybcxm engines listed on the placard as 718.3 cubic centimeters. The vin is cecb08471k900. Are these 717 or 720 Rotax engines or are they something entirely different that the company tried and failed at for only a year or so? I called the dealer. they looked up the vin, but I got the impression they are pretty clueless about a boat this old.

any search I do for a "2000 sea-doo challenger" only results in boats with a 6 cylinder Mercury 2 stroke engine. any search I do a year or two earlier only results in the 1800 model.

I've literally spent hours searching.....What the heck am I doing wrong? I know my boat isn't an anomaly.

this is my first experience with a sea-doo or a Rotax but I've had several boats in the past and I have a ton of experience fixing all things mechanical.

I have tons of other questions.....I just don't know where to begin.

This boat has really low hours (maybe 50-100), has never been in salt, but has been sitting for perhaps 4 years. All 4 cylinders have 150+lbs of compression. they are original to the boat with shiny silver paint. they have never been taken apart but the carburetors appear to have been removed previously. so far, the carbs are off pulled off to be rebuilt. the oil tank and fuel cell have been drained. I pulled off the outdrives today and found I need a shaft protector and 2 shaft seals.

I want to replace the spark plugs and bleed the air out of the oil system since I took it apart. there are about a dozen or so minor parts I have written in my notebook that I need to replace. I just wish I knew where to look?

why is this so difficult for me? anyone with advice and a willingness to steer me in the right direction would be greatly appreciated.

regards,

Brian

Last edited: