lakeeriejoe

New Member

Some background:

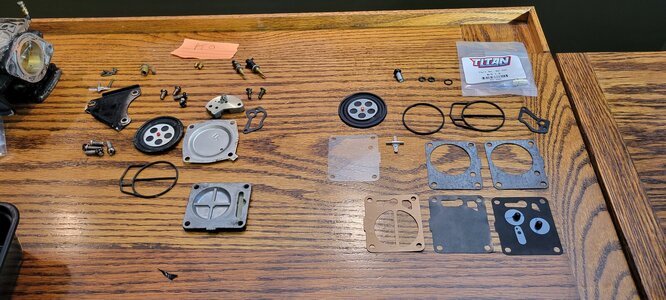

I am handy with home projects (remodeled a bathroom down to the studs among other smaller projects) but when it comes to cars/engines/mechanical things like that, I am very green. Purchased some late 90's skis two years ago and one had continuing problems which most people seemed to think pointed to carbs needing rebuilt (787 engine). So alas, I finally pulled them a few weeks ago and just this week had time to start tearing them down. I have all of the internal parts removed and this is what I have encountered so far:

I am handy with home projects (remodeled a bathroom down to the studs among other smaller projects) but when it comes to cars/engines/mechanical things like that, I am very green. Purchased some late 90's skis two years ago and one had continuing problems which most people seemed to think pointed to carbs needing rebuilt (787 engine). So alas, I finally pulled them a few weeks ago and just this week had time to start tearing them down. I have all of the internal parts removed and this is what I have encountered so far:

- Stripped screw hole for cover plate on PTO side carb (the plate housing the fuel filter)..and no, I didn't do it.

- Speaking of fuel filters, NEITHER carb had one

- Stripped pilot jet on PTO carb (this WAS probably me...think my screwdriver had too much wiggle room/movement, but I was impatient on finding something better. I had to use the torx screw (T10) trick, worked like a charm (had to drill as well)

- Stripped metering block check valve screw on PTO side (this may have been me, not sure), I found a better screwdriver (this one isn't JIS is it?) for the MAG side. I again used the torx trick to remove it.

- I must say, other than the issues with stripping and such, the inside of the carbs appear pretty clean, no gunk, no blocked seats or jets, etc.

- Best chemical(s) to clean the parts that I have removed?

- MAG side adjustment screw with the "T" handle...it doesn't have a "point" end, is that correct? Basically just a screw that manually pushes on the butterfly?

- As I understand it, the PTO side uses NONE of the diaphrams/gaskets (save for the circular one w/ the red thing in middle) from the kit, correct?

- For the MAG side, does it use ALL diaphrams/gaskets? There are three cardboard-like gaskets, I know I use the one that is tan/brown as it is the one I had to spend an hour scraping/sanding off the block. I know I use the two thin black gaskets as well as the clear one (and the small circular ones). The kit also has two grey-ish looking gaskets, do these get used? Pics attached for reference