I am glad to be helpful, you're welcome!

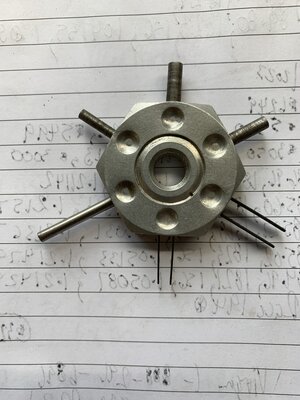

The better pin extractors had a solid rod in the center that you can push the pin out from the front side with, as opposed to pulling it out

from the backside. Damaged pins and sockets are difficult to remove when the latching barbs are all deformed, pressure must be applied from the backside against the metal crimped on end. holding the insulation on the wire with hemostat or needle nose, usually will be rigid enough, while you work the tube over the barbs from the front side. You will probably have to replace the damaged pin, so I would get the replacement pin first,

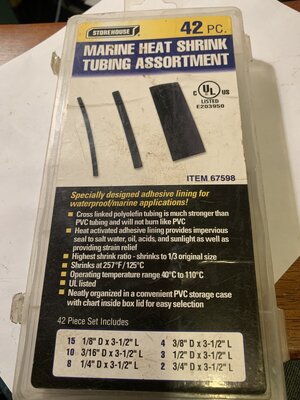

to get a better idea of what you up against. I have tried saving pins for re-use, but that W-crimp is so tight, its almost impossible to un-do. But with enough wire left attached to it, a guy could splice it in, soldering and marine heat shrink.

Digressing from the subject:

I read a lot of posts regarding electrical issues, without mention of the copper in wires being infiltrated by corrosion, under the insulation.

I live by the beach, so my skis are only used in salt water which seems to attack copper. I've found battery cables infected, also smaller 16ga stranded copper wire. Usually feeling the insulation for bumpy, or stiff places will help locate the infection, and when stripping back insulation

to expose the copper, sometimes there's only a few strands still continuous through the powder left from the other "decomposed" copper strands.

I see a lot of this in trailer lights wiring, but also engine wiring. I cut back the wire until I finds bright and shinny copper, then do a "westerm union" splice and solder it, then the marine grade heat shrink tubing that has a clear glue lining on the inside, and shrink it until this glue oozes out both ends. Liquid rubber is an alternative.

Hope this helps someone.