As title says.

Worked on a few Yami's that had them within engine, most were dusted, replaced. Installed/replaced a few on Kawi's @ pump area, stand alone & not as a washer that secures components as some owners did.

My family & I religiously flush after every ride with salt away. The lake that we go 70% of the time to is considered to have comparably high salinity but still in the "brackish" column. That lake has a high KIA record.

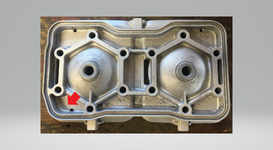

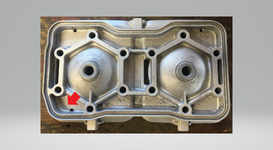

As the pics will testify to, The previous owner & his teenage sons neglected to flush &/or sat for years still "wet". Mind you, this engine only has 40.3 hrs

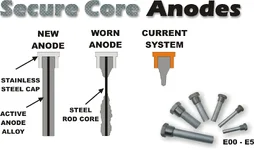

So, considering installing an aluminum pencil anode so as to arrest damage done & as a preventive measure. The arrows denote possible placement. Notice the anode would be placed off center & above metered drain.

Has anyone done or seen this & did it have detrimental effects? Positive?

Worked on a few Yami's that had them within engine, most were dusted, replaced. Installed/replaced a few on Kawi's @ pump area, stand alone & not as a washer that secures components as some owners did.

My family & I religiously flush after every ride with salt away. The lake that we go 70% of the time to is considered to have comparably high salinity but still in the "brackish" column. That lake has a high KIA record.

As the pics will testify to, The previous owner & his teenage sons neglected to flush &/or sat for years still "wet". Mind you, this engine only has 40.3 hrs

So, considering installing an aluminum pencil anode so as to arrest damage done & as a preventive measure. The arrows denote possible placement. Notice the anode would be placed off center & above metered drain.

Has anyone done or seen this & did it have detrimental effects? Positive?