So I’ve been working on my xp for awhile now, finally I’ve gotten it all put back together and running. But when I start it the engine immediately runs at 6 to 7000 rpm with NO throttle. I’ve confirmed this by checking the throttle flaps in the carb and the cable connection to the carb assy. My mind immediately went to check valves on fuel tank pressure release. But there’s no clogs. I did replace the oem pressure release valve with a normal check valve that I bought on Amazon. They are fully functional though and I went through them tonight and started the engine again and… same problem. Only thing I can think is maybe the tank is providing enough pressure to boost the fuel and cramming fuel in, but not enough to push air out of the check valves? It makes no sense to me. Any help is appreciated. Thanks!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

98 Seadoo xp 951 fuel tank pressurizes and forces fuel out overflow of carb

- Thread starter dash75966

- Start date

Ok but how is an air leak causing extreme pressures in the tank. I feel like it should be the opposite if I have a leak somewhere. I’m fairly certain there is not any air leaks though because I’ve pressurized the tank manually and it held pressure until I released it by opening the gas cap. Throttle is the screw on top of the right side right? Right above the pulse line and overflow?

The tanks do build up pressure just from heat and fumes and the pressure relief is at about 1.5-2 psi.

The air leak we are speaking of is between the carbs and crankcase, not the fuel system. If you have air leaking in below the carbs it will cause an extreme lean condition and it will run at high rpm with no spark just like a diesel.

951's are very susceptible to this because they run lean due to emissions. To prevent a runaway on a 951 set the idle to about 1300 out of the water, no air leaks, do not rev it high out of the water with the throttle.

The idle screw is on the front carb and opens the throttle butterfly.

The air leak we are speaking of is between the carbs and crankcase, not the fuel system. If you have air leaking in below the carbs it will cause an extreme lean condition and it will run at high rpm with no spark just like a diesel.

951's are very susceptible to this because they run lean due to emissions. To prevent a runaway on a 951 set the idle to about 1300 out of the water, no air leaks, do not rev it high out of the water with the throttle.

The idle screw is on the front carb and opens the throttle butterfly.

Ok that’s good to know, I did have the studs that hold the back carb break off so maybe the gasket slid off while I was putting it on. That would make a lot of sense since there’s that horrible exhaust pipe on top which makes it hard to see and work on. I’ll check when I get home.

so I thought the carbs were tight on there, but I remembered I didn’t crank them down that much so I went ahead and did my best to tighten them. Still it runs wild at 8000 rpm’s. I don’t think there’s an air leak between my carbs, there’s new gaskets on there. I ran it without the gas cap on and there’s still fuel pouring out the overflow. Any ideas? I can’t believe how close I am but at the same time how far.  Is it possible there’s just a lot of fuel that needs to be burned off before it idles correctly? I’ve read about the runaway 951 but I just can’t pin down why this one is happening. At this point I’m afraid to run it anymore because I have no hose connected to it and it’s not in the water because I can’t get it to work properly.

Is it possible there’s just a lot of fuel that needs to be burned off before it idles correctly? I’ve read about the runaway 951 but I just can’t pin down why this one is happening. At this point I’m afraid to run it anymore because I have no hose connected to it and it’s not in the water because I can’t get it to work properly.

JC-SUPERJET

Active Member

Were the Carbs rebuilt correctly with Genuine Mikuni Kits? Did you do a Pop-off test on the Carbs?

A bad, stuck or incorrectly seated Needle Valve will allow unrestricted Fuel to pass into the Carb Throats. Maybe the Spring(s) is jammed/off center.

What are you calling the Carb "Outflow"?

Did you do an Air Leak-down Test on the re-assembled Engine prior to installation?

Were all the Crankcase Hose Nipples reconnected and none left open?

Is the RAVE Valve System connected and working properly without leaks?

Is the Exhaust Pipe leaking at the big Clamp Joint?

Download a Free Seadoo Manual and read....

A bad, stuck or incorrectly seated Needle Valve will allow unrestricted Fuel to pass into the Carb Throats. Maybe the Spring(s) is jammed/off center.

What are you calling the Carb "Outflow"?

Did you do an Air Leak-down Test on the re-assembled Engine prior to installation?

Were all the Crankcase Hose Nipples reconnected and none left open?

Is the RAVE Valve System connected and working properly without leaks?

Is the Exhaust Pipe leaking at the big Clamp Joint?

Download a Free Seadoo Manual and read....

I rebuilt the carbs with an osd marine kit which is equivalent to the genuine mukini parts. Yes I did a pop off pressure test, although I didn’t have a pressure gauge so I just pumped a lot of pressure in to make sure it would hold the pressure. No idea how much psi was actually in the carb. Needle valve should be good. Carb overflow that I’m referring to is the nipple directly above the pulse line connection. It is highly pressurized no matter what I do. I did not rebuild the inside of the engine or crankcase or any of that, just removed it to clean the hull. To my knowledge yes I have connected all the hoses back on the engine. Is there a way to check the seal on the exhaust pipe? I’m fairly certain it’s sealed correctly because there’s no smoke leaks or anything. I don’t think it would effect engine rpm’s anyways. Not sure about the rave valves, how would I check that they’re functioning correctly? I’m guessing my problem is directly related to the overflow line with pressurized fuel. Any ideas on why it’s forcing fuel out and why it’s pressurized?

JC-SUPERJET

Active Member

Assuming the Carbs were rebuilt correctly and the Gas Cap was off (thereby eliminating Vapor Pressure), then the Return Line would have to be clogged somewhere between the Carb Return Nipples and the Fuel Tank.

If the Return Line is clogged/blocked, that would bring the entire Fuel Pump Pressure to bear on the Needle Valves causing them to crack open all the time and dump fuel into the Carb Throats.

To check this, route the Return Line from the Tank into a small Container which allows one to see Fuel leaving the Carbs. If it is not "returning", then the Carb Return Nipple or Hose is blocked.

At Idle, normal Return Line Fuel Pressure is about 2 psi, give or take. Could place a TEE and Pressure Gauge in the Return Line to check pressure.

By the way, how can you see Fuel dribbling down the Carb Throats? Do you have a Mirror?

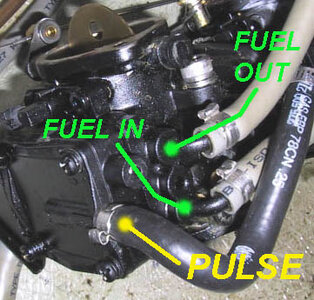

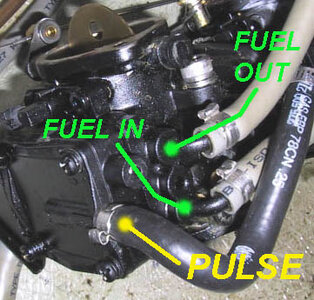

Are you sure the Fuel Supply Hose is connected to the correct Carb (Low) Nipple? And the Return Hose is connected to the Correct (High) Nipple? The Supply is the bigger Hose (5/16?) and the Return is the smaller Hose (1/4?). Is the Pulse Line connected to the right Nipple?

If the Hoses are mixed up, then the Engine would be sucking Fumes from the Fuel Tank or Crankcase via the Return or Pulse Line and running away as that would make for an extremely LEAN Mixture.

Is the Fuel Selector Switch in good working condition? It could also be allowing Air into the Fuel Supply Line to the Carbs. Can bypass the Switch to verify.

And how about the Accelerator Pump? Was it inspected and rebuilt? Removed?

If the Return Line is clogged/blocked, that would bring the entire Fuel Pump Pressure to bear on the Needle Valves causing them to crack open all the time and dump fuel into the Carb Throats.

To check this, route the Return Line from the Tank into a small Container which allows one to see Fuel leaving the Carbs. If it is not "returning", then the Carb Return Nipple or Hose is blocked.

At Idle, normal Return Line Fuel Pressure is about 2 psi, give or take. Could place a TEE and Pressure Gauge in the Return Line to check pressure.

By the way, how can you see Fuel dribbling down the Carb Throats? Do you have a Mirror?

Are you sure the Fuel Supply Hose is connected to the correct Carb (Low) Nipple? And the Return Hose is connected to the Correct (High) Nipple? The Supply is the bigger Hose (5/16?) and the Return is the smaller Hose (1/4?). Is the Pulse Line connected to the right Nipple?

If the Hoses are mixed up, then the Engine would be sucking Fumes from the Fuel Tank or Crankcase via the Return or Pulse Line and running away as that would make for an extremely LEAN Mixture.

Is the Fuel Selector Switch in good working condition? It could also be allowing Air into the Fuel Supply Line to the Carbs. Can bypass the Switch to verify.

And how about the Accelerator Pump? Was it inspected and rebuilt? Removed?

Last edited:

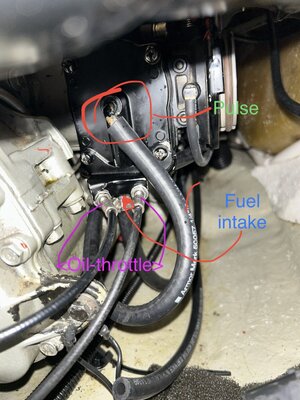

So I’ve done some other things tonight to try and confirm the fuel overflow. First off my carbs are not the same as your picture. My carbs look quite different. I’ll post a picture of what mine look like and my connections. But anyways the fuel return has nothing to do with it. I tested it with a separate line and bottle to see what was happening and it did lower the rpm’s a tiny bit. I think it was running about 5000 instead of 7000 but it’s probably just because the length of the line was shorter so there was less pressure. Although there is an enormous amount of fuel return. Is that normal, I’m guessing since you said 2psi was normal return pressure that it is. You’ve got me thinking maybe I’ve got my lines a little mixed up, so let me know if I’m right. I’ve looked at diagrams so I think it’s correct but you can’t be to sure.  I also forgot to mention I videoed the inside of the front carb during it running. And I really can’t see any fuel or anything. I also took the coil connectors off and just turned it over while I videoed the back carb but I didn’t do it while running. Still no fuel dripping or anything though.

I also forgot to mention I videoed the inside of the front carb during it running. And I really can’t see any fuel or anything. I also took the coil connectors off and just turned it over while I videoed the back carb but I didn’t do it while running. Still no fuel dripping or anything though.

Last edited:

You still have an air leak somewhere.

If the throttle butterflies are closed and it is dumping fuel in it will flood out, not rev to 8000. The only way it is going to get to 8000 is if the butterflies are held open (even a little) or air is getting in below the carbs.

I also don't see any clamps on any of your fuel lines which could be sucking air causing a lean condition.

Is the orange RTV from the pipe?

If the throttle butterflies are closed and it is dumping fuel in it will flood out, not rev to 8000. The only way it is going to get to 8000 is if the butterflies are held open (even a little) or air is getting in below the carbs.

I also don't see any clamps on any of your fuel lines which could be sucking air causing a lean condition.

Is the orange RTV from the pipe?

Last edited:

ok I do seem to remember when I put the carbs on that there was a small gap in the throttle butterflies. But I assumed it was an idle gap. Is there supposed to be a complete seal there?

Yes the RTV is from the pipe, but I also used it to hold down the brass choke barrel set screw bc it stripped out. I know it’s not a permanent fix but it’s been working for me for right now. I’m just trying to get it to work properly before I look into more permanent fixes for small things like that.

Yes the RTV is from the pipe, but I also used it to hold down the brass choke barrel set screw bc it stripped out. I know it’s not a permanent fix but it’s been working for me for right now. I’m just trying to get it to work properly before I look into more permanent fixes for small things like that.

At Idle yes, there is a very small gap in the butterflies.

Have you tried backing out the idle screw?

Better yet, when your ski goes to 8000 rpm does hitting the stop button or pulling the lanyard turn it off?

Back out the idle screw until it isn't touching the throttle shaft. then snap the throttle on the bars and see if you can hear bot butterflies actually close. If you verify they are actually closing then set the idle screw 1-1/2 turn in once it touches the lever and it should start.

The only time I have seen runaway skis is if the idle is set too high or if there is an air leak.

Have you tried backing out the idle screw?

Better yet, when your ski goes to 8000 rpm does hitting the stop button or pulling the lanyard turn it off?

Back out the idle screw until it isn't touching the throttle shaft. then snap the throttle on the bars and see if you can hear bot butterflies actually close. If you verify they are actually closing then set the idle screw 1-1/2 turn in once it touches the lever and it should start.

The only time I have seen runaway skis is if the idle is set too high or if there is an air leak.

Yeah I’ve fully backed it out. It’s at the lowest it could be. It does rev higher when I give it throttle though. I don’t know if this is normal, but it happens. How would I go about connecting it with a hose? There’s 2 inlets in the pump, one on the left and one on the right. One is much longer than the other. Which do I use? Both? All I can think of is maybe there was fuel to burn off inside and I need to run it a minute. I always shit it off fast because I don’t want to overheat it outside the water.

Man @mikidymac thanks a lot for that last one! Turns out my throttle cable was just barely too tight and I loosened it and now she runs like a champ!

This is why this forum is worth its weight in gold and the annual membership fee!

Similar threads

- Replies

- 34

- Views

- 1,370

- Replies

- 14

- Views

- 713