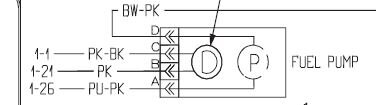

i have a 2004 rxp supercharged and i wasnt getting fuel to the fuel rail so i replaced the fuel pump and made sure the lines wearnt clogged, still wasnt getting fuel so i pulled the NEW fuel pump and tested it outside of the ski. it worked, so then i put a multi meter on the electrical line giving power the pump and i get 10v i have good ground as well. there seems to be a timer because when i put the key in i get 10v for exactly 10sec then i dont get power at all to the pump. all of the connections on the pump are good and i get good power from the battery to the connection on the pump but as soon as i hook it up i dont get power. extremely weird. any help is very much appreciated!!

-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

2004 rxp no power to fuel pump

- Thread starter rjquinn

- Start date