CASPX

New Member

Well after 2 years I'm almost finally done with my motor rebuild thanks in part to a lot of the guys on here so I figured it's about time for a rebuild thread.

Have 2 1997 SPX's both bought new in 1997 and used for only about 10-15 hours over the course of 13 years in the port of Long Beach, Salt Water. Of course as they age things start to happen and one of the first things that happen was the pipe plug rotting through and creating a hole which was discovered after about a 2 hour ride in the ocean. Removed the pipe welded in a new plug and called it good. Used the skis 2 or 3 more times until about 4 years ago when I found this forum and read about all the fuel line issues. So I replaced all the grey temp lines with trident marine fuel line, cleaned the carbs, filters, selector, fixed the fuel gauge baffle, changed the jet pump oil, replaced the oil filters, and polished & waxed them including the trailer.

One always had starter issues, replaced one starter and the replacement stopped working so I pulled them both and they where covered in what looked like dirt. I disassembled both of them cleaned them, greased them, & tested them. Both worked good so I stuck the OEM one back in the bike and took it to the local lake for memorial day 2013. Both bikes ran good fr most of the day until we parked them for the afternoon. When we tried to leave and the starter would just spin so towed it back to the launch.

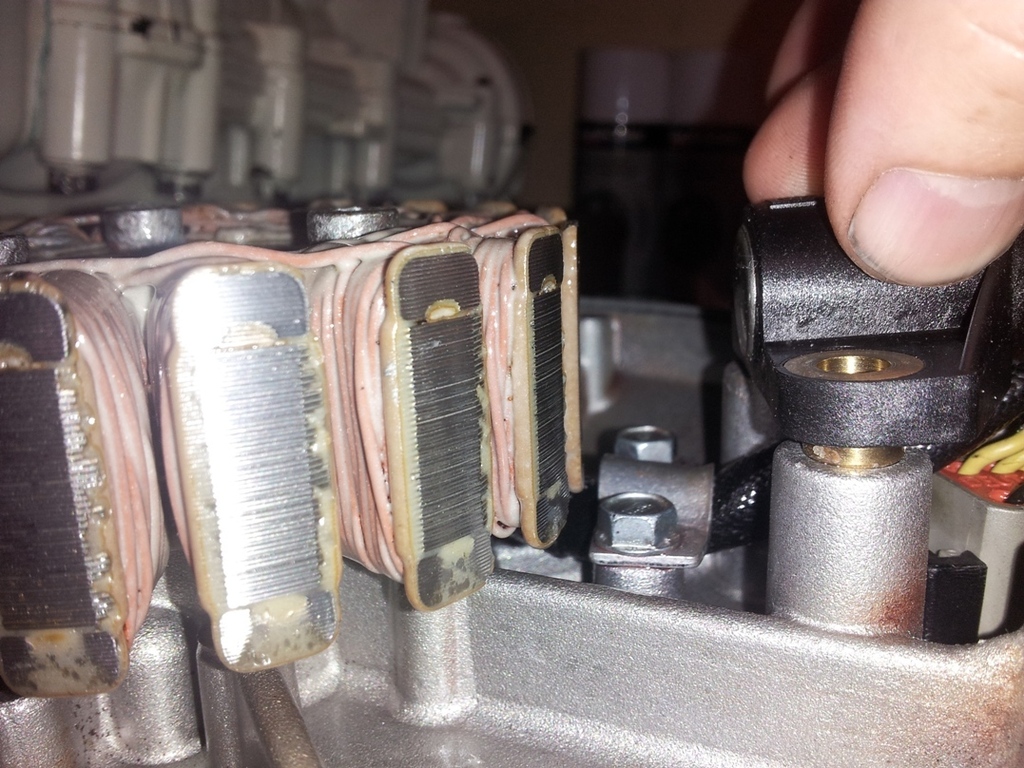

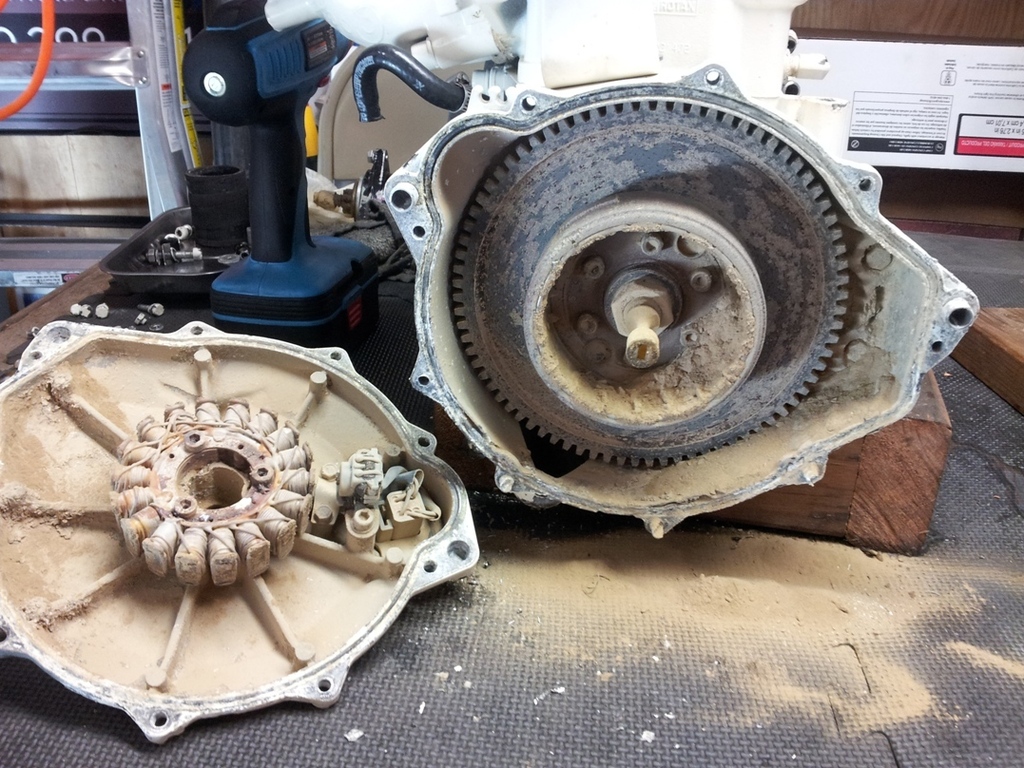

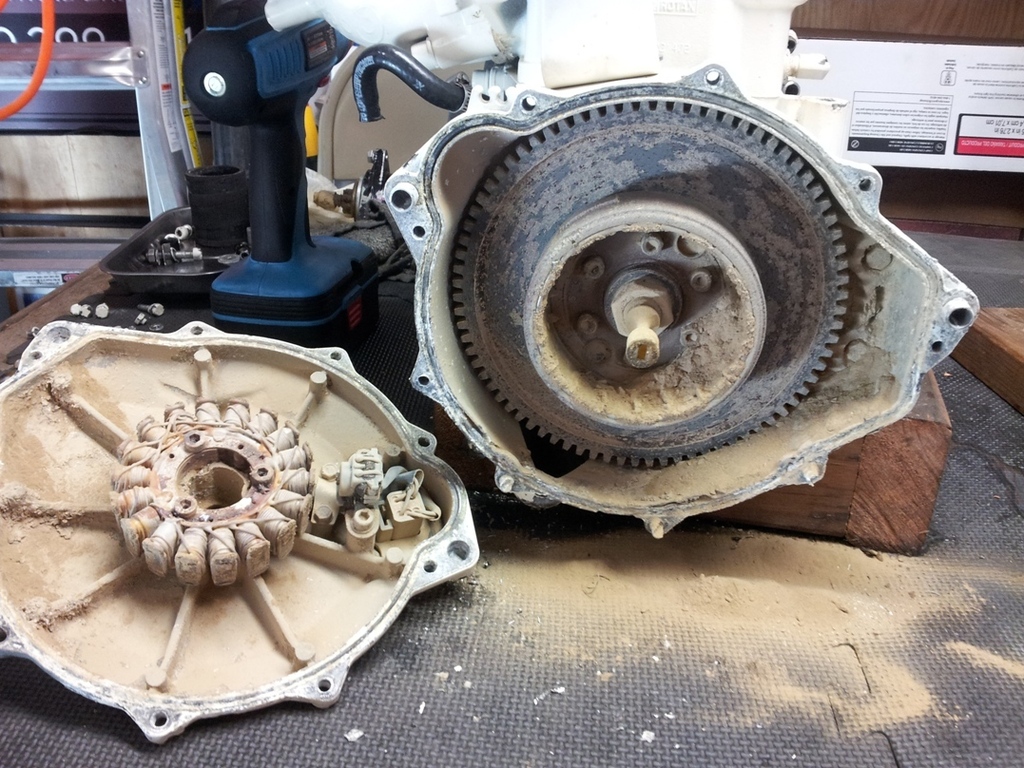

After all that work I decided that I'd try to find out what the problem was so after digging in to it for 5 hours I said F-it and pulled the motor. When I cracked open the stator here's what I found.

I've come to the conclusion that salt water got blasted in to the stator cover through the Deustch stator plug on the front of the housing when the pipe plug went and sat in there for probably 8-10 years then we'd grind it up with the occasional 2 hours of use every 4-5 years. You can see the water line on the back of the stator housing.

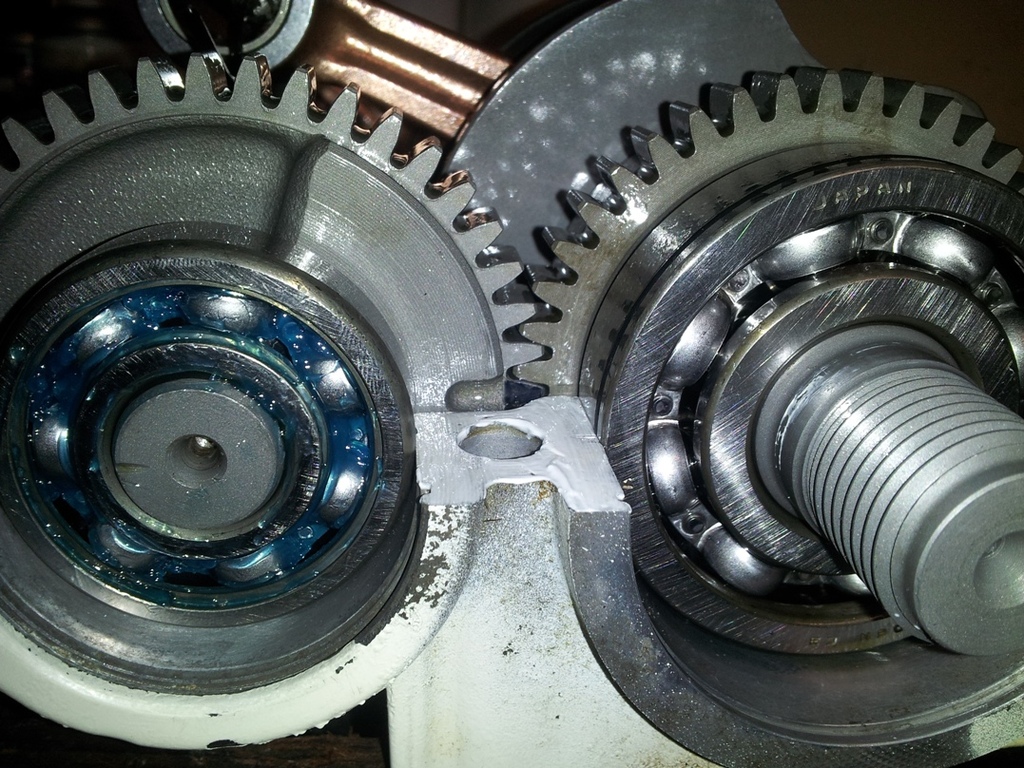

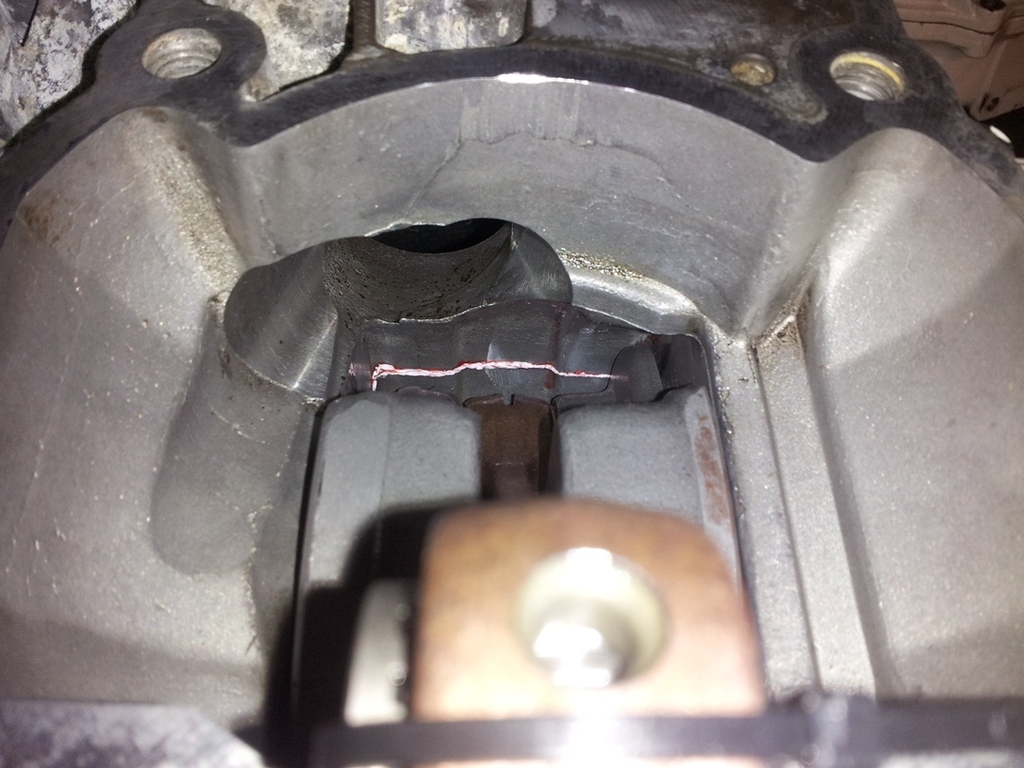

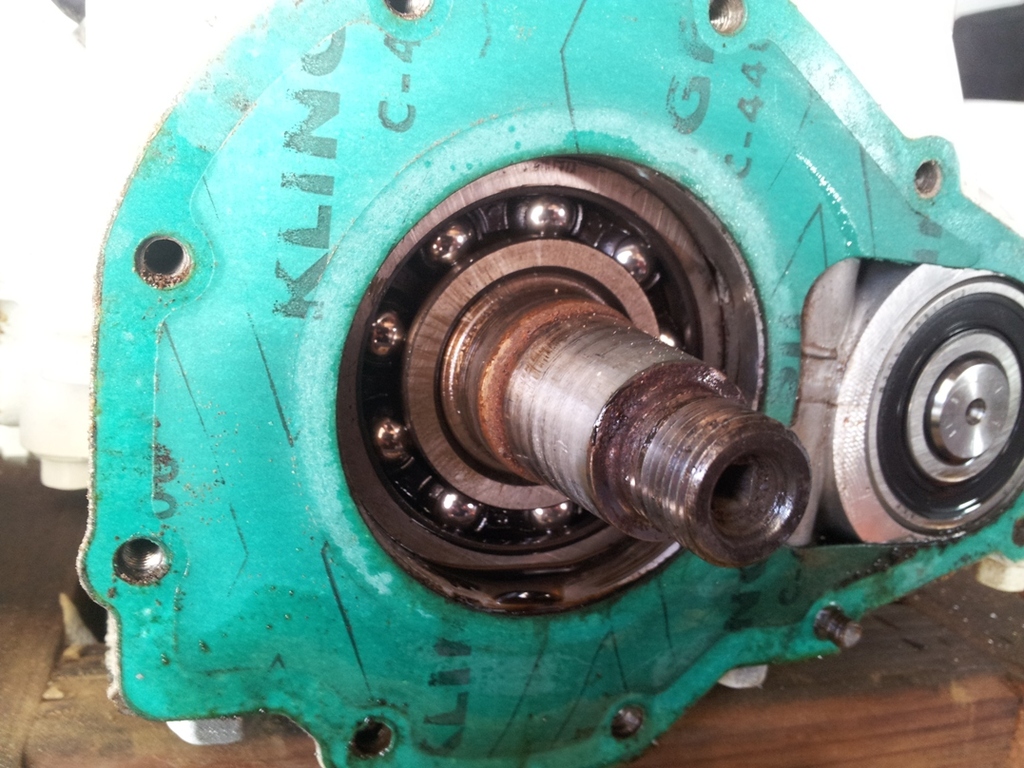

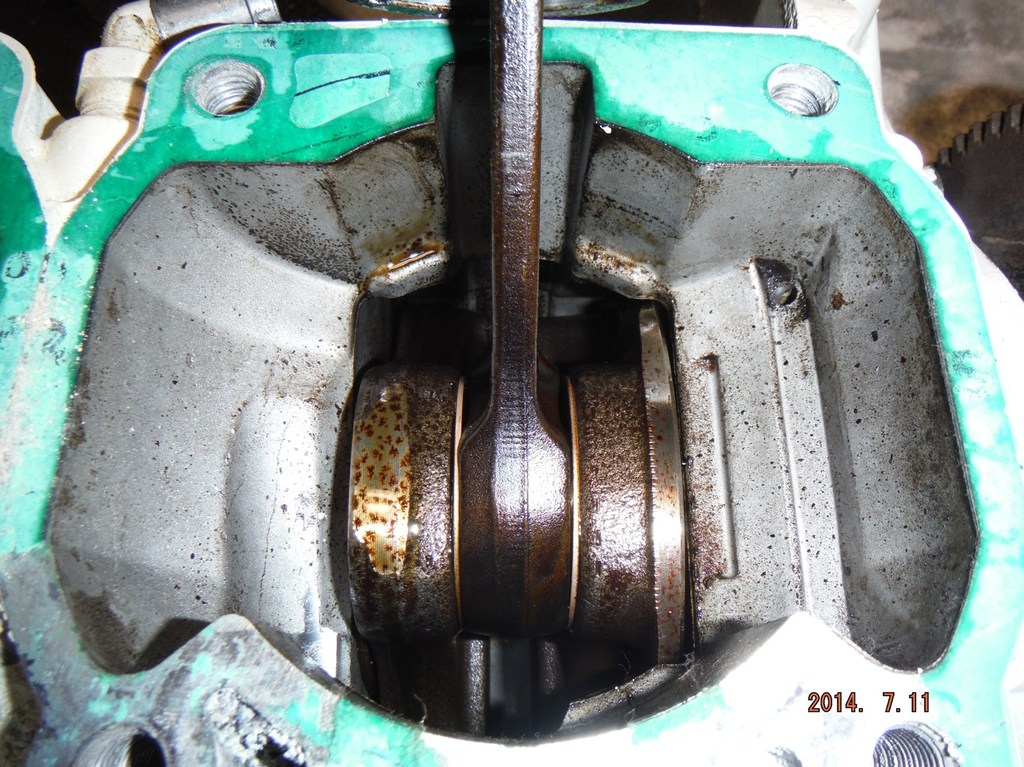

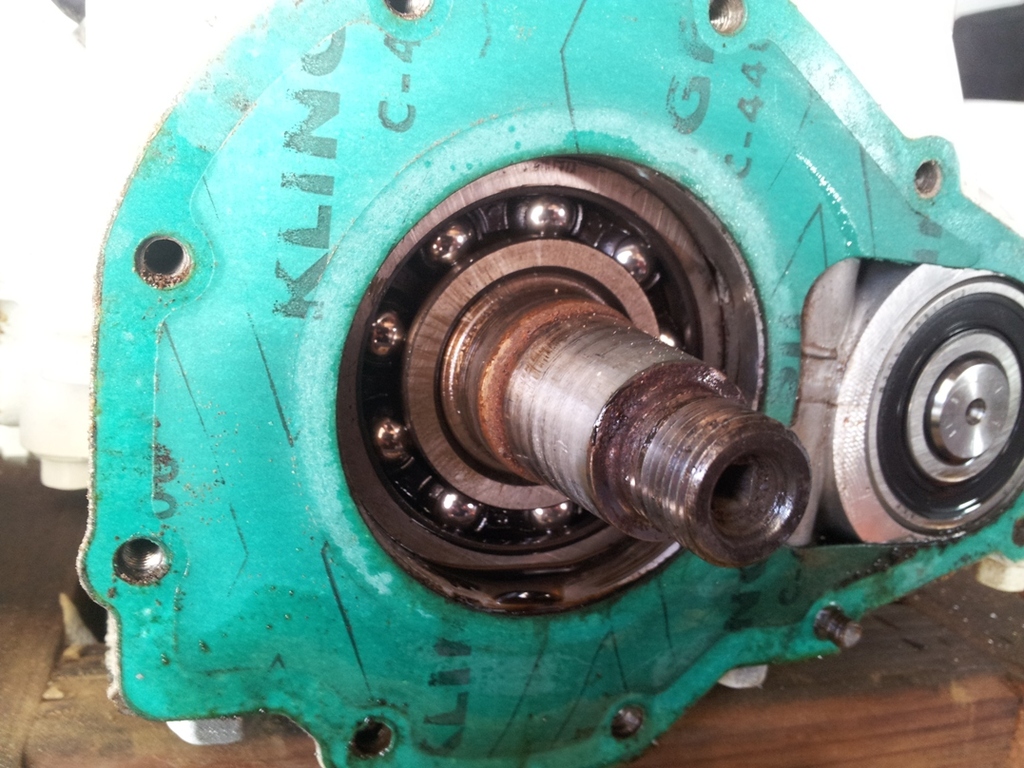

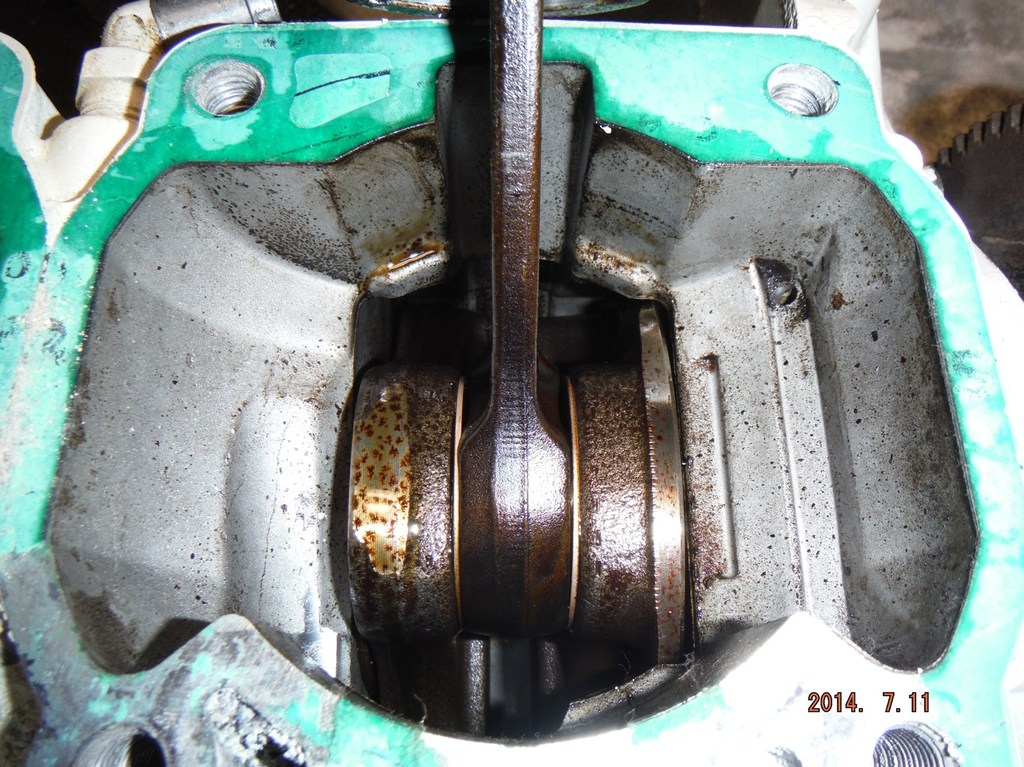

So after learning a little more I decided it was probably best to tear the motor all the way down and rebuild it VS risking blowing it because of a compromised crank seal. So here’s what I found when I dug in to it.

Have 2 1997 SPX's both bought new in 1997 and used for only about 10-15 hours over the course of 13 years in the port of Long Beach, Salt Water. Of course as they age things start to happen and one of the first things that happen was the pipe plug rotting through and creating a hole which was discovered after about a 2 hour ride in the ocean. Removed the pipe welded in a new plug and called it good. Used the skis 2 or 3 more times until about 4 years ago when I found this forum and read about all the fuel line issues. So I replaced all the grey temp lines with trident marine fuel line, cleaned the carbs, filters, selector, fixed the fuel gauge baffle, changed the jet pump oil, replaced the oil filters, and polished & waxed them including the trailer.

One always had starter issues, replaced one starter and the replacement stopped working so I pulled them both and they where covered in what looked like dirt. I disassembled both of them cleaned them, greased them, & tested them. Both worked good so I stuck the OEM one back in the bike and took it to the local lake for memorial day 2013. Both bikes ran good fr most of the day until we parked them for the afternoon. When we tried to leave and the starter would just spin so towed it back to the launch.

After all that work I decided that I'd try to find out what the problem was so after digging in to it for 5 hours I said F-it and pulled the motor. When I cracked open the stator here's what I found.

I've come to the conclusion that salt water got blasted in to the stator cover through the Deustch stator plug on the front of the housing when the pipe plug went and sat in there for probably 8-10 years then we'd grind it up with the occasional 2 hours of use every 4-5 years. You can see the water line on the back of the stator housing.

So after learning a little more I decided it was probably best to tear the motor all the way down and rebuild it VS risking blowing it because of a compromised crank seal. So here’s what I found when I dug in to it.

Last edited by a moderator: