BrianMoore

Member

Carburetor question about the high speed check valve.

Background. 1997 GTI. Two years ago while camping with the family, son-in-law says what about a family jetski? All the men say hell yes, women say hell no. So my son-in law got this ski and trailer from the original owners for $1. They take really good care of their stuff and have only dealers work on it. This boat had no major work done on it, only maintenance. But our family knows that grandpa, me, can fix anything. It didn’t start 7 years before and was sitting since. The fuel filter was completely clogged. Rebuilt with an OEM kit. Changed out the fuel lines. There was low compression, 110 PSI, on the original motor. But it started and we ran it last summer. Only issue was a bog at ¼ throttle. That was solved by opening up the throttle a lot and wait a second or so for it to rip.

But I didn’t trust that really worn engine. Last fall I picked up a SeaDoo factory rebuilt short block. I was really surprised how well it had been running with rusty cylinders, pistons knocking around, blown crank seals, and .020” rotary valve clearance. I never touched the carb. I broke it in for a few hours and the bog was intermittently there. Last week we took it out on the Columbia and started riding it like normal. The bog came back at times. Other than that it ran really well. With the rotary valve fixed, it starts really well when cold. Starts instantaneously when warm.

I was coming back in for the last time to load it up and it died about 10 feet from the dock. Wind is about 35 MPH pushing me back into the channel and the ski refused to start. It would fire for a few cycles with the choke on but wouldn’t run. Then the rescue adventure began as I floated downstream. Back at home I tore back into the carb. I really expected clogged transfer ports or a clogged filter. All those were good. Finally I noticed the high speed mylar check valve was curled and not sitting flush with the block. The little piece of stuff under it was a bit of Cristolube. It is a silicone grease I put on a couple o-rings to make it easier to get apart if I was ever into the carb again. I am never using that again since it never deteriorates in fuel and even using it very sparingly it ended up somewhere else. I gently got the speck of grease out and the check valve was still curled wher it had not been curled after the carb rebuild. Removed and reinstalled the check valve and it was still curled. I got the original check valve I had saved and it went on flat as it should. Ski fires right up now. I have not taken it out on the water yet so I don’t know if the bog is gone.

Question one is why did the mylar strip curl? It is genuine Mikuni so I don't think it is a quality issue.

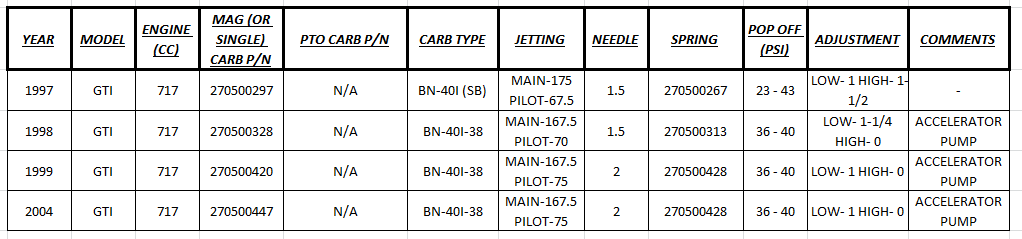

Second question is about accelerator pumps. Seadoo started using them in 1998 from what I see. Was that to overcome the bog I am seeing on this boat with no accelerator pump?

Brian

Background. 1997 GTI. Two years ago while camping with the family, son-in-law says what about a family jetski? All the men say hell yes, women say hell no. So my son-in law got this ski and trailer from the original owners for $1. They take really good care of their stuff and have only dealers work on it. This boat had no major work done on it, only maintenance. But our family knows that grandpa, me, can fix anything. It didn’t start 7 years before and was sitting since. The fuel filter was completely clogged. Rebuilt with an OEM kit. Changed out the fuel lines. There was low compression, 110 PSI, on the original motor. But it started and we ran it last summer. Only issue was a bog at ¼ throttle. That was solved by opening up the throttle a lot and wait a second or so for it to rip.

But I didn’t trust that really worn engine. Last fall I picked up a SeaDoo factory rebuilt short block. I was really surprised how well it had been running with rusty cylinders, pistons knocking around, blown crank seals, and .020” rotary valve clearance. I never touched the carb. I broke it in for a few hours and the bog was intermittently there. Last week we took it out on the Columbia and started riding it like normal. The bog came back at times. Other than that it ran really well. With the rotary valve fixed, it starts really well when cold. Starts instantaneously when warm.

I was coming back in for the last time to load it up and it died about 10 feet from the dock. Wind is about 35 MPH pushing me back into the channel and the ski refused to start. It would fire for a few cycles with the choke on but wouldn’t run. Then the rescue adventure began as I floated downstream. Back at home I tore back into the carb. I really expected clogged transfer ports or a clogged filter. All those were good. Finally I noticed the high speed mylar check valve was curled and not sitting flush with the block. The little piece of stuff under it was a bit of Cristolube. It is a silicone grease I put on a couple o-rings to make it easier to get apart if I was ever into the carb again. I am never using that again since it never deteriorates in fuel and even using it very sparingly it ended up somewhere else. I gently got the speck of grease out and the check valve was still curled wher it had not been curled after the carb rebuild. Removed and reinstalled the check valve and it was still curled. I got the original check valve I had saved and it went on flat as it should. Ski fires right up now. I have not taken it out on the water yet so I don’t know if the bog is gone.

Question one is why did the mylar strip curl? It is genuine Mikuni so I don't think it is a quality issue.

Second question is about accelerator pumps. Seadoo started using them in 1998 from what I see. Was that to overcome the bog I am seeing on this boat with no accelerator pump?

Brian